What Are Cardboard Boxes? All You Need to Know About Cardboard Packaging

.jpg)

Cardboard boxes are fiber-based containers used for shipping, storage, and packaging. Most shipping boxes are corrugated cardboard made with a wavy flute sandwiched between two liners for strength, while retail cartons use paperboard. These boxes ship flat and are easy to recycle.

Businesses in operations, supply chain, and procurement departments need packaging that fits specs, arrives on time, and supports brand goals. Cardboard boxes are the perfect answer for all of them. These boxes for a wide range of industries from pharmaceuticals to cosmetics.

Cardboard packaging is a proven way for brands to ship products safely, look good on the shelf, and control costs. This type of packaging plays an important role in the modern day business environment and economy. A cardboard box is lightweight, cost effective, and easy to fold that makes it ideal for transportation.

We have written this detailed blog that gives you clear answers without any irrelevant information. You get the basics, the options, and the steps that matter when you source custom boxes at scale. You also get quick tips, common box types, and simple tables for tests and sizes.

Let’s get started.

Key Takeaways

- Cardboard boxes are either corrugated cardboard for shipping or paperboard for retail packaging.

- Corrugated box strength comes from the inner flute profile plus liner weight and tests like ECT.

- Box manufacturing follows a repeatable flow from pulp to folding and gluing, then packing and pallets.

- Common types include RSC, FOL, die-cut custom, and folding cartons for branded items.

- Right flute and board grade cut damage, returns, and freight costs for e-commerce and wholesale.

- Boxes ship flat, store well, and are easy to recycle when clean and dry.

- Printing choices range from simple one-color to high-impact retail print for packaging.

- Moisture, overstacking, and poor pallet patterns reduce box strength and lead to crush.

- Working with a reliable shipping box supplier speeds up quotes, sampling, and change control.

What is a Cardboard Box?

A cardboard box is a fiber-based container made from corrugated cardboard or paperboard for packaging, shipping, and storage. Corrugate adds strength using a wavy flute between liners, while paperboard serves retail packaging with clean print. Both formats ship flat, assemble fast, and recycle easily.

History of Cardboard Boxes

Cardboard packaging started with stiff paperboard cartons in the 1800s for dry items and soap. Corrugated cardboard arrived soon after as a stronger shipping carton. Over time, better liners, coatings, and flute options built the modern corrugated box used across global supply chains.

Materials Used in Cardboard Production

Materials in cardboard production support print, strength, and cost.

- Virgin Kraft liner made from softwood pulp

- Recycled liner and medium from recovered fiber to support recycle goals

- The corrugating medium that we corrugate into the flute

- White bleached paperboard for retail packaging

- Starch adhesive is used to bond the flute to the liners

- Water-based inks, varnishes, or aqueous coatings

- Specialty packaging material like tear tapes, easy-open zips, or window films

Main Features of a Cardboard Box

In warehouses and on the shelf, cardboard boxes are great for drive performance due to their outstanding performance on the shelf.

- High strength-to-weight due to flute geometry

- Ships and stores flat for space saving

- Accepts barcodes, lot codes, and color print

- Works with tape, staples, or glue for folding and closure

- Scales from small mailers to large carton sizes

- Easy to recycle when free of food or oil

A well-specified cardboard box supports product safety, brand clarity, and cost control across your packaging program.

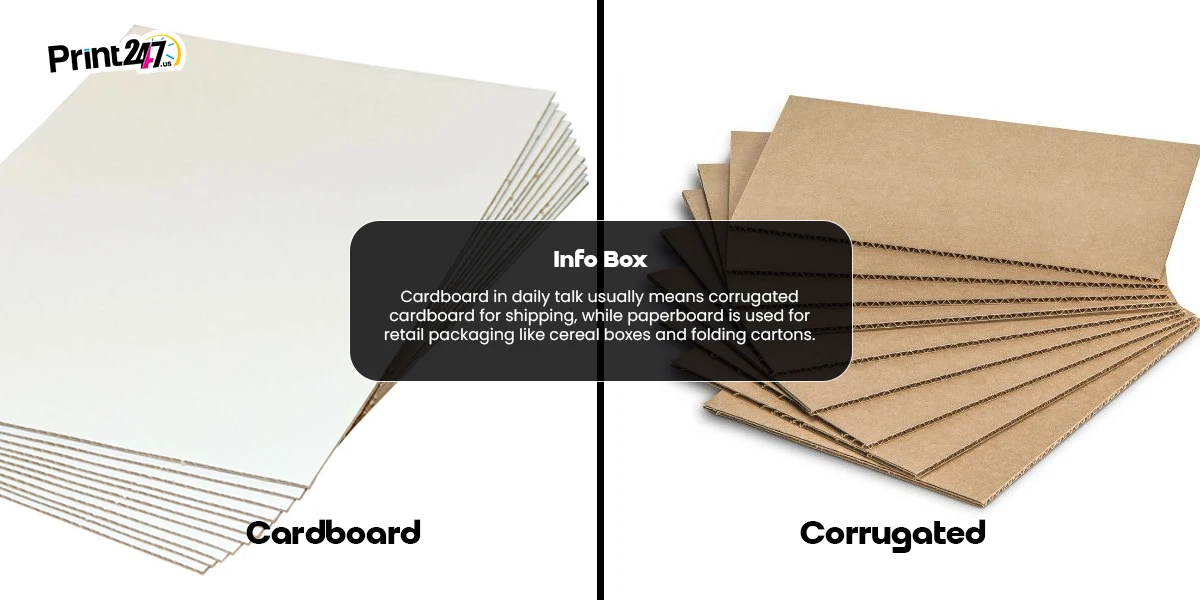

The Difference Between Cardboard vs. Corrugated

Cardboard is a broad term people use for both shipping and retail boxes, while corrugated refers to a specific board made with a wavy flute between liners. Corrugated cardboard handles shipping and stacking, while paperboard serves retail cartons with high print quality.

Cardboard vs. Corrugated Comparison

What Are Flutes in Cardboard? What Are the Types of Flutes?

Flute is the wavy paper in corrugated cardboard that creates vertical columns for stacking strength and cushioning. Flute height and count per foot set the crush resistance and print surface. Larger flutes cushion better, smaller flutes print cleaner and fold tighter, so manufacturers match flutes to product, route, and storage.

Common Flute Types and Uses

With the right flute choice, pallets will stack better, damage will be reduced, and packaging costs will stay in line.

Tip Box

Match flute to supply chain: long parcel routes like boxes for moving may prefer C or B flute for a mix of crush and print, while beauty retail packaging often uses E or F for fine graphics and tight folding.

What is the Process Of Manufacturing Cardboard Boxes?

Cardboard packaging manufacturing processes follow a clear flow from fiber to finished carton with checkpoints that protect quality and lead time. During the process, paper is converted to board, blanks are printed and cut, then the boxes are folded and glued. You can achieve better crush ratings, prints, fits, and speeds at each step of the process.

Here’s the step by step for cardboard packaging

Step 1: Pulping and Papermaking

Mills turn wood chips and recovered fiber into pulp with the help of digesters and refiners. They form sheets on a paper machine, dry them, and wind liner and medium rolls.

Step 2: Corrugating the Medium

Plants heat and corrugate the medium into a flute, apply starch, and bond it to one or both liners to make a single face or board. The flute height can be 0.8 mm to 4.8mm.

Step 3: Slitting, Scoring, and Sheeting

Cutting and creasing large sheets is an important part of cardboard manufacturing. In converters, rolls are scored to width, fold lines are scored, and sheet boards are trimmed to length for each cardboard box style.

Step 4: Printing

Cost-effective printing methods like flexo, digital, or litho print add barcodes, brand marks, and instructions for packaging lines and retail packaging.

Step 5: Die Cutting

Flat or rotary tooling creates slots, tabs, and windows for RSCs, mailers, or die-cut custom carton designs. It’s a high-speed process to cut the cardboard precisely.

Step 6: Folding and Gluing

It's the critical final stage in cardboard packaging manufacturing. These lines apply glue, fold the boxes, and knock them down so they can be shipped and stored flat.

Step 7: Quality Checks and Palletizing

The team verifies size, Mullen or ECT, print, and glues pallets, then wraps and stages them for outbound shipments.

What Are Different Types of Cardboard Boxes?

Cardboard boxes include shipping, retail, and specialty types that fit different loads, print needs, and routes. Corrugated cardboard is most often used for shipping, whereas paperboard can be used for display and retail units. The choice you make is influenced by the product weight, stack height, print goals, and carton unit count.

Here are more details about each type of cardboard packaging.

Single Wall Corrugated Box

A single wall corrugated box uses one flute between two liners. It handles most parcel and light pallet loads with good print and value. It works well for e-commerce product lines, cross-dock shipments, and general packaging boxes with standard ECT like 32 or 44, depending on weight.

Double Wall Corrugated Box

A double wall corrugated box stacks two flute mediums and three liners. It supports higher stacking and longer storage. Use it for heavy units, larger packaging boxes, and mixed pallets that see pressure changes. It is a smart pick for appliances, auto parts, and bulk shipping boxes.

Triple Wall Corrugated Box

A triple wall corrugated box adds a third flute layer similar to plywood in strength. It is used for very heavy or fragile items that require high crush and puncture resistance. Pallet boxes and export crates benefit from this level for long routes and tougher material handling.

Regular Slotted Container (RSC)

An RSC is the most common cardboard box style with flaps that meet in the center. It is fast to set up, tape, and stack. It fits automated lines and is cost-effective for many SKUs. Most packaging programs start with RSCs for clean spec control and easy recycling.

Full Overlap Box (FOL)

An FOL has long flaps that fully cover the top and bottom. It adds extra layers for edge and face strength. It is useful for narrow, heavy, or fragile items and for routes with rough handling. Teams often pair it with corner boards for better stacking.

Die-Cut Custom Box

A die-cut box is a custom cardboard carton with precise cuts, vents, locks, and closures. It ships flat, sets up clean, and can reduce void fill. Retail mailers, subscription kits, and branded shippers use this to add a better unboxing experience with less material waste.

Folding Carton

A folding carton is a paperboard box for retail packaging like cosmetics, food sleeves, and OTC items. It prints very well, stores flat, and sets up quickly on cartoners. It is not a shipping box, so teams often pair it with an outer corrugated box for transit.

Rigid Setup Box

A rigid setup box is a thick paperboard box that arrives pre-assembled. It gives a premium look for gifts, luxury items, and brand kits. It protects the finishes well, but costs more to ship and store due to volume. Many teams use it for VIP kits and special launches.

What Are the Applications of Cardboard Boxes?

Cardboard packaging applications are wide-ranging and support a multitude of business cases from online orders to wholesale pallets. Businesses choose cardboard box type by weight, route time, stack needs, and display goals. The right specification reduces damage and keeps freight costs in line while keeping brand print clean and readable.

E-commerce Shipping

E-commerce brands use RSCs and die-cut mailers for safe parcel moves. The right flute and void fill prevent crush and scuff. Easy-open features, print inside panels, and return labels improve the user experience. Boxes must scan clean for hubs and arrive ready to recycle.

Product Retail Packaging

Retail brands use paperboard folding cartons for shelf impact and SKU density. Litho or high-end digital print delivers color accuracy and small text. Cartons pair with outers for ship-to-store or ship-to-DC. Hang tabs, windows, and coatings support planogram goals in retail packaging.

Moving and Storage

Moving services and warehouses rely on sturdy cardboard boxes for moving with clear packing labels and hand holes. Standardized sizes stack well, use C flute for crush, and keep items safe. Boxes work with bubble, foam, or paper pads and are loaded into large shipping boxes or bins.

Food and Beverage Packaging

Food and beverage brands use coated corrugated boxes and paperboard sleeves that meet food-contact guidance. Chill and moisture can soften the board, so coatings and the right flute help. Clear date codes and barcodes support traceability and cold chain checks.

Industrial and Heavy-Duty Shipping

Heavy items ship in double or triple wall corrugated cardboard with reinforced seams. Pallet boxes and bulk bins reduce unit load cost. Teams test with ECT or Mullen and, when needed, add straps, corner posts, and liners to reduce puncture.

Gift and Subscription Boxes

Subscription brands favor custom die-cut mailers with high-impact print. Inserts hold items snug, and tear-strips make the opening clean. Boxes must balance print with fiber content to keep recycle streams clean. Right-size box sets reduce DIM and freight fees.

What is The Importance of Cardboard Packaging?

Cardboard packaging is a core supply chain resource that lowers damage, protects brand assets, and supports sustainability goals. Good specs align with your pick-pack, pallet patterns, and carrier mix. With clean print and the right flute, your packaging boxes do their job and save money throughout the year.

Here are more details about the importance of cardboard boxes in our regular lives.

Cost-Effective Packaging

Costs stay in line due to efficient fiber use, flat shipping, and fast setup. Correct board grade prevents damage that drives returns. Volume pricing and standard footprints add more savings.

Lightweight & Reduces Shipping Costs

Fiber-based boxes weigh less than many alternatives. Lower mass helps with DIM charges, fuel surcharges, and manual handling limits. Teams see savings across parcel and LTL lanes.

Highly Recyclable & Eco-Friendly

Clean, dry cardboard is easy to recycle in most programs. Recovered fiber feeds new liner and medium, which supports brand sustainability goals and helps meet retailer scorecards.

Excellent Protection & Cushioning

The flute acts like a spring that resists crush and absorbs shocks. Right board plus inserts cut in-transit moves that cause scratches, dents, and breakage.

Fully Customizable (Size, Print, Strength)

You can set size, die-cuts, coatings, windows, and print. Board grade scales from light mailers to bulk bins. This helps teams match box to product and route.

Easy to Store & Handle (Flat-Pack)

Boxes are shipped flat and stored in a flat place. The pallets of blanks slide into racks and flow smoothly to the pack stations. This saves time on the floor and keeps aisles clear.

Versatile for Almost Any Industry

From packaging supplies to packaging solutions for electronics, food, beauty, and auto, the format fits many needs. Brands add branded items and shipping supplies to create full kits.

Final Thoughts

To conclude this, cardboard boxes give brands a simple, strong, and smart way to move products through complex routes. A solid spec links your team’s goals to real-world results, like fewer damages, faster pack times, and less freight waste. When you need a partner to guide custom packaging design, testing, and rollout, choose Print247. We are a leading local US packaging supplier that supports free design help, eco-friendly options, fast shipping, and physical samples so your team can test before you scale. With the right corrugated cardboard or paperboard choice, the right flute, and clear folding and print specs, your packaging material works as hard as your product.

FAQs

What is a cardboard box?

A cardboard box is a fiber-based container used for shipping, storage, and retail packaging. Shipping versions use corrugated cardboard with a flute core and liners for strength, while retail cartons use paperboard that prints cleanly. Both ship flat, assemble fast, and are easy to recycle when clean.

Is a chipboard the same as cardboard?

A chipboard is a type of paperboard without a flute, used for folding cartons, pads, and sleeves. Cardboard in shipping usually means corrugated cardboard built with liners and a flute for crush strength. They serve different roles in a full packaging system.

What is another name for a cardboard box?

Another common name is a carton for retail units or an RSC for a standard shipper. Teams also say case, shipper, or master pack. The term corrugated box points to shipping-grade boards with a flute between liners.

What is the most durable type of cardboard?

Triple wall corrugated cardboard offers very high crush and puncture resistance due to three flute layers and heavy liners. It is used for bulk bins, export crates, and very heavy items where stack height and long routes demand stronger packaging material.

What qualifies as cardboard?

Cardboard refers to thick fiber sheets used for packaging. It includes paperboard for retail packaging and corrugated cardboard for shipping. Both start from pulp, form into sheets, then convert into boxes by folding, cutting, and gluing.

Are cardboard boxes compostable?

Many plants prefer recycling cardboard rather than composting uncoated cardboard, since fiber is more easily repurposed by recycling. Avoid composting if the board has plastic films, heavy inks, or oil. Always check local rules before you divert from recycling streams.

Are cardboard boxes toxic?

Standard cardboard boxes use starch adhesives and water-based inks. When certified for contact or indirect food contact, they meet strict standards. Avoid putting oily or hazardous items inside without liners or approved barriers, and always recycle clean boxes.

.jpg)

.jpg)

.jpg)