What Is Paperboard Packaging? A Comprehensive Guide to Types and Uses

.jpg)

Paperboard packaging is a thick, recyclable, and flexible paper-based board used for retail cartons, sleeves, and inserts. It is made from wood pulp or recycled fiber, pressed into sheets, then coated for high print quality. Brands use it for clean graphics, lightweight, and easy recycling across food, beauty, and healthcare.

If you sell products in stores or ship them in cases, you need a packaging solution that looks sharp, runs fast, and keeps costs in check. Paperboard packaging does that job well. It is the familiar cereal box material, yet today’s grades handle barcodes, lot codes, windows, foil, and tough line speeds.

In this guide, we are going to explain what a paperboard is, how it is made, where it beats other options, and how to choose the right grade. You will see the types of paperboard, how to frame paperboard vs cardboard, the real advantages of paperboard packaging, the main paperboard packaging materials, and simple ways to support sustainable paperboard packaging without losing shelf appeal.

The paper and paperboard packaging market is expected to expand by 4.28% by 2034, from USD 337.64 billion in 2025 to USD 492.33 billion in 2034. (Source: Towards Packaging)

What is Paperboard Packaging?

Paperboard packaging is a versatile and rigid packaging that is thinner than cardboard packaging. It’s a finished structure made from paperboard material and specifically designed to protect products. Its creation process includes die-cutting, scoring, folding, and gluing. Examples include medicine cartons, frozen pizza boxes and cosmetic folding cartons.

It folds clean at the crease, glues fast, and stacks well. It is the go-to for folding cartons, sleeves, trays, and retail-ready packs. It also supports packaging teams that track packaging sustainability goals across regions.

What is a Paperboard?

Paperboard is a multi-ply, thick, paper-based sheet made from virgin or recycled pulp. It offers a smooth print face, enough stiffness for shape, and a caliper that supports creasing and folding. Brands use it for folding cartons, sleeves, and custom paperboard boxes across beauty, OTC, snacks, and small electronics.

How is Paperboard Made?

Mills turn wood chips and recovered paper into pulp, clean it, and form a wet web on a wire. Layers are pressed, dried, and finished in a calendaring stack that sets smoothness and gloss. A clay or polymer coat may be added. This paper pulp production creates stable paperboard grades with repeatable pack performance.

What Are the Different Types of Paperboard Packaging?

Packaging plays a vital role in each industry. There are 4 main types of paperboard grades that are used to manufacture packaging for various industries. Each type has its own advantages and disadvantages and varies in characteristics.

There is a balance between strength, appearance, and cost for each grade. You should choose based on your filling line, print requirements, and route to market. In this section, you will find information about the main types of paperboard used by brands.

Solid Bleached Sulfate (SBS)

.webp)

SBS is made from virgin bleached fibers, which is often coated with a clay-based material on the top of the surface. It has a bright white core and a smooth coated face. The clean shade helps color match and fine text. SBS holds foils, emboss, soft-touch, and spot UV well.

It resists odor transfer, which makes it a common food safe paperboard for chocolate, bakery, and pharma inserts. It is a premium choice when you need a brand white that is precise. SBS is a good choice for hero products, seasonal gift sets, and medical device IFUs where small barcodes and batch codes are necessary. Short digital runs can also be run with SBS, which gives a steady ink laydown similar to offset.

Coated Unbleached Kraft (CUK)

.webp) CUK uses strong unbleached kraft fibers with a white coated face. The brown back signals a natural feel without marketing copy. It has high tear and some wet strength options, which helps in cold chain and condensation. Beverage carriers, multipacks, and frozen lines often use CUK because the board holds shape when damp.

CUK uses strong unbleached kraft fibers with a white coated face. The brown back signals a natural feel without marketing copy. It has high tear and some wet strength options, which helps in cold chain and condensation. Beverage carriers, multipacks, and frozen lines often use CUK because the board holds shape when damp.

It also supports cutout handles without fast tearing. For brands with an eco look, the Kraft back inside the carton adds a warm tone. Think six-pack carriers, freezer sleeves, and rugged retail trays. Many teams call it Kraft paperboard, and it pairs well with water-based coatings for eco-friendly packaging stories.

Coated Recycled Board (CRB)

.webp)

CRB is a recycled paperboard made with multiple plies and a white coated top. It is often called chipboard packaging and is widely used in high-volume packaging. The core can be gray or brown. Coated Recycled Board gives strong value and supports paperboard recycling goals.

Print is crisp on the coated side, though you should avoid tiny reverse text at very low ink limits. CRB is great for puzzles, toys, dry foods, and seasonal packs. It also shines in club store trays and secondary displays. Smart structural design can compensate for slightly lower stiffness at the same caliper compared with SBS. Maintain clean edges by adjusting your converter's crease rules.

Folding Boxboard (FBB)

.webp)

FBB is a layered board that blends mechanical and chemical pulps with a bleached liner. It is common in Europe and now growing in North America. FBB is very stiff for its weight, which helps reduce material use. If your team wants lightweight packaging without a dull look, FBB is a strong option. The surface is smooth and bright, which supports fine graphics and foil. Beauty and confectionery brands like FBB for its hand feel and flatness. If you run global SKUs, FBB helps align specs across regions where this grade is standard.

Common Uses of Paperboard Packaging

Paperboard is one of the most commonly used packaging materials due to its versatility, excellent print quality, and high sustainability. It serves high-volume markets because it balances print quality and line speed. It ships flat, saves space, and runs on automated folder gluer lines.

Here are core use cases with simple examples to guide your spec.

Retail Folding Cartons used in stores and display trays

Retail cartons are the face of your brand on the shelf. A moisturizer carton in SBS shows skin tones with tight color. A vitamin carton in CRB hits cost targets while keeping codes readable. A power bank carton in FBB stays stiff even in a thin caliper, which helps prevent panel sag.

Food and Beverage Sleeves that wrap trays and multipacks

By using sleeves, you are able to add billboard space without heavy packaging. Yogurt 4-pack sleeves in CUK are designed to withstand cold rooms and light condensation. A frozen entrée sleeve in SBS with a grease barrier keeps oil from showing through. Clear windows or cutouts help shoppers see the product while saving material.

Pharma and Healthcare kits that need clean print and codes

Pharma cartons need neat panels for instructions, lot codes, and safety icons. SBS and FBB run well in tiny text and print. Cartoners easily feed inserts and medication guides because they stay flat. Consequently, less line stoppage occurs and fewer reprints are necessary.

Confectionery and Gourmet packs that carry gift appeal

Chocolate, cookies, and tea brands use SBS or FBB paperboard for foil, emboss, and soft-touch. A holiday sleeve can carry the product information without changing the inner tray. Windows show the product while the board protects edges from chipping in transit.

Retail Inserts and Headers for bagged goods and blister cards

Using paperboard inserts, you can store earbuds, cables, and small tools inside clamshells or bags. In terms of cost, CRB offers value for larger runs, while SBS offers a bright surface for logos that must be color-critical. With the right grain direction, the paperboard provides excellent fold strength and hole tear resistance for hanging header cards.

Paperboard Packaging vs. Other Materials

Choosing the right material is easier when you compare how each behaves on the line, in the truck, and on the shelf. The table sets a quick overview for teams weighing corrugated vs paperboard and related picks.

Paperboard vs. Cardboard

Corrugated “cardboard” wins for crush and stacking. It protects heavy or fragile items moving alone through a parcel system. Paperboard is best for shelf look, space savings, and fast gluing. Many brands use paperboard for the retail box and corrugated for the outer shipper.

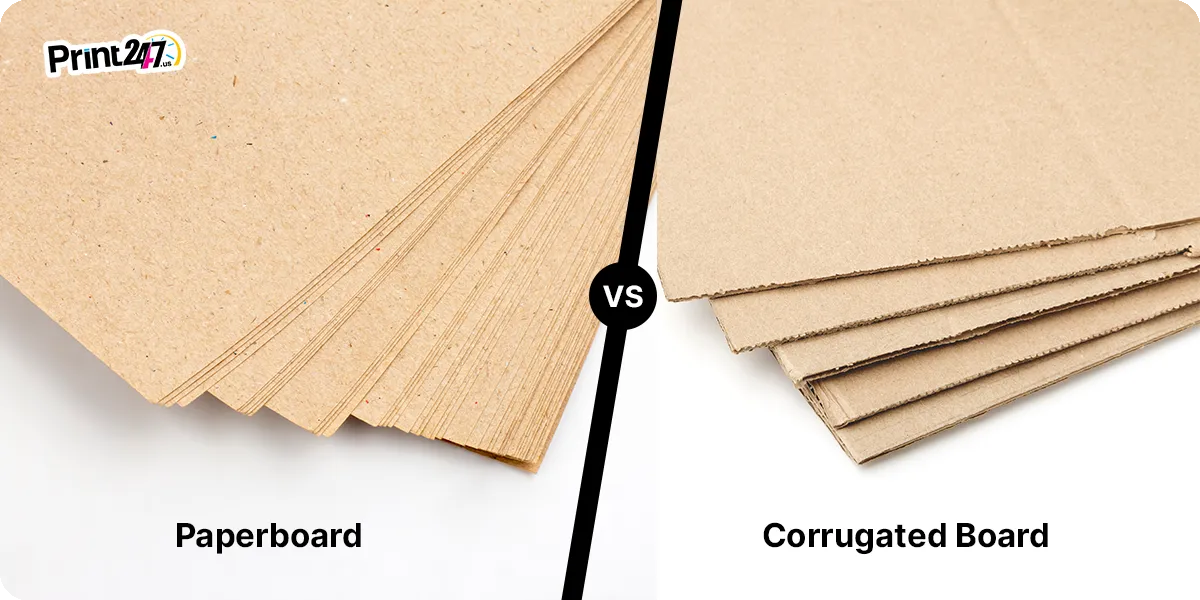

Paperboard vs. Corrugated Board

For single-item shipping or warehouse stacking, corrugated is the safer option. For shelf sets or inner packs that live inside a master case, paperboard gives better graphics and a lower cost per unit. You can add paperboard inserts to hold parts in place.

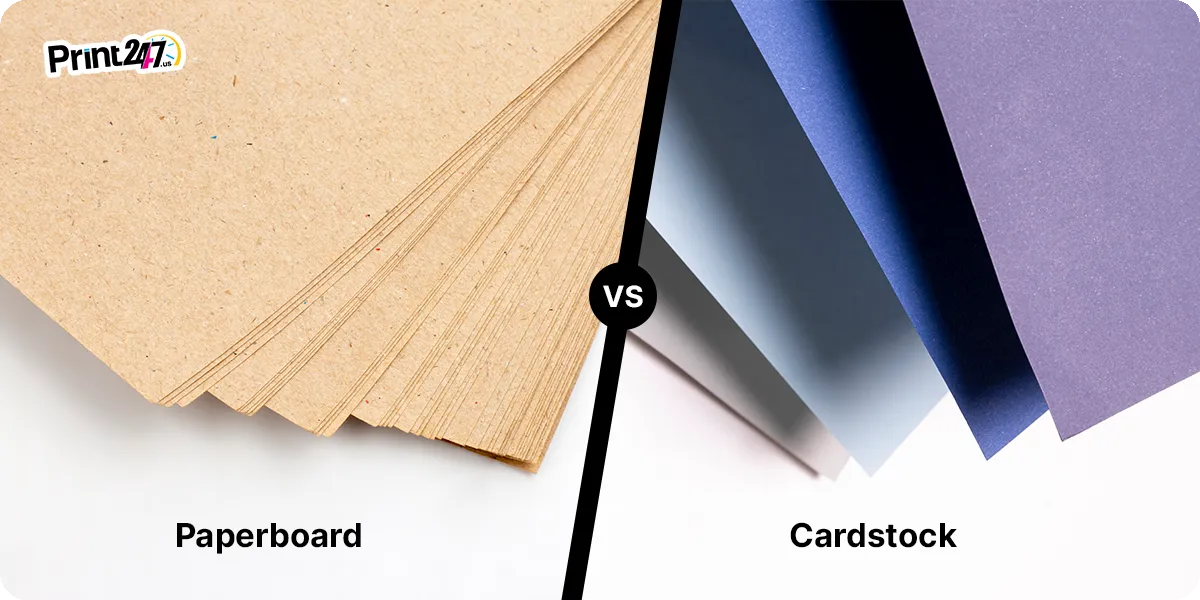

Paperboard vs. Cardstock

Cardstock is a thicker, flexible, and often decorative paper. With its bright surface and smooth structure, it offers vibrant colors and a high level of contracting power. The paperboard has defined caliper, stiffness, and coatings. High-speed cartoners can easily handle it because it folds cleanly and holds its shape.

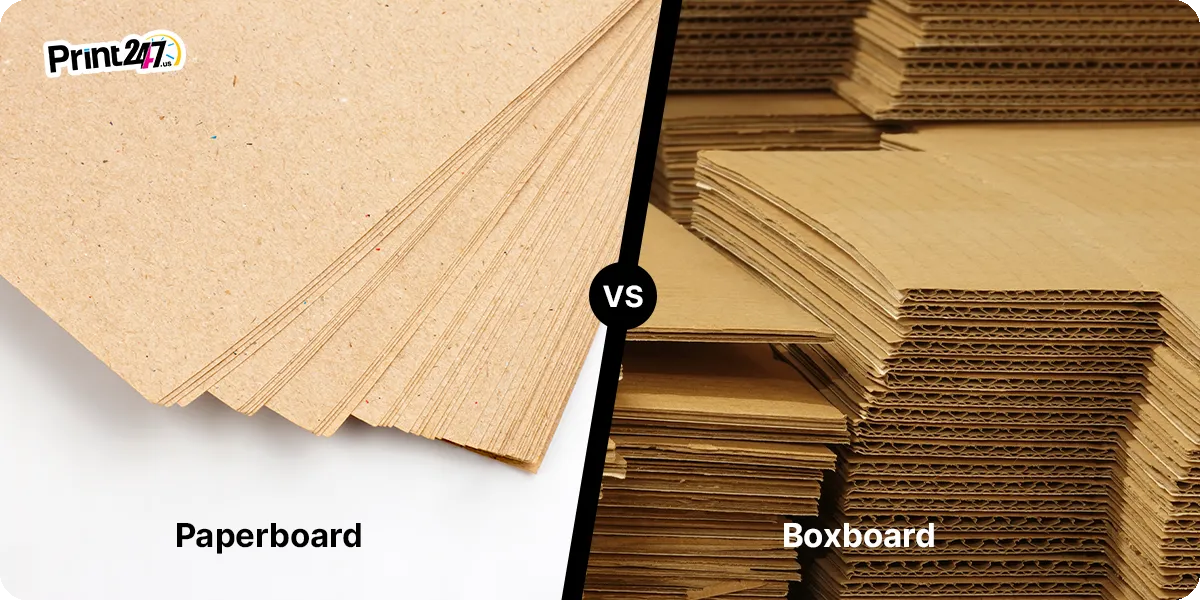

Paperboard vs. Boxboard

Boxboard is a strong kraft-based utility board often used in bulk or industrial packs. It is strong but rough. Paperboard gives a smoother surface and brighter print for consumer-facing panels. If your brand relies on color and clean edges, paperboard is the better face.

Popular Finish Techniques for Paperboard Packaging

Visual experience is the deciding factor in a consumer's purchasing choice. Paperboard is highly suitable for various types of finishes due to its smooth surface. Each finish choice ultimately affects on paper grade.

Paperboard supports offset and digital print with sharp text and images. Aqueous coats protect from rub and fingerprints. Soft-touch, foil, and emboss add premium cues. Window patching shows the product while keeping dust out.

For food, choose coatings tested for contact or migration. Share your folder gluer model, speed target, and adhesive with your converter. Good crease design, correct grain direction, and the right glue flap help you hit rate without jams.

Conclusion

Paperboard packaging gives brands a strong mix of print quality, speed, and recycling. It helps you hit shelf dates, protect color, and control cube. With SBS, CUK, CRB, and FBB, you can fine tune weight, shade, and strength by SKU.

If you want an easy path from idea to line-ready custom packaging, talk to Print247. We are a leading local US packaging manufacturer that offers free design support, eco-friendly materials, fast shipping, and physical samples.

Our team of packaging experts can choose the right paperboard thickness and build custom paperboard boxes that match your budget and timeline. We help you balance paperboard vs cardboard in the full supply chain so your retail pack and your shipper work as one.

Order paperboard packaging now at Print247 and give your brand an uplift.

FAQs

What paperboard grade works best for small glass jars?

For light jars under 8 ounces, start with 20 to 24 pt SBS or FBB. Add a paperboard insert or a simple tray for added top-load support. If the jar is oily, use a grease-resistant coat. Test a short run to confirm crease and glue at your line speed.

Is paperboard packaging the same as cardboard packaging?

No. They are often used interchangeably, but are different in terms of structure, strength, and purpose. Paperboard is made of a single layer, while corrugated cardboard is made of multiple layers. Paperboard is mostly used in primary packaging, while cardboard is used in secondary packaging.

How do I choose between SBS and CRB paperboard?

Pick CRB if your main goal is cost control with a solid print face. Use SBS if your colors are critical and include fine gradients or skin tones. Run drawdowns for both and review text at small sizes. Many brands use CRB for value SKUs and SBS for hero SKUs.

Can paperboard handle freezer and condensation?

Yes, with the right grade, paperboard packaging can handle freezer temperatures. CUK with wet strength is common for beverage carriers and some frozen foods. Coated SBS and FBB also work when paired with moisture-resistant coats. Always test on your exact line with your cold room settings to confirm glue and fold.

What coatings should I use to reduce scuffing on dark colors?

Aqueous gloss lowers rub on rich blacks and deep blues. Matte gives a softer look to paperboard packaging, but it can show marks. Therefore, consider a protective overcoat on high-touch panels. Keep ink densities within your printer’s limits to prevent set-off during stacking.

Is a chipboard the same as recycled paperboard?

“Chipboard” commonly refers to coated recycled board with a gray or brown core and a white top. It is a form of recycled paperboard. It prints well for many dry goods and seasonal items. Use care with tiny reverse text and confirm print limits with your vendor.

Can I add windows and still recycle the paperboard carton?

Yes, if the window area is small and the film peels off during recycling. Ask about bio-based or easy-release films. Keep windows away from main creases for better folding. Window patching works well on SBS and FBB for a clear product view.

.jpg)

.jpg)

.jpg)