Why Transparent Barcode Labels Are a Game Changer for Retail Business?

.jpg)

Transparent barcode labels help retailers keep products neat, easy to scan, and on brand. They blend with packaging, keep key artwork visible, and work on glass, plastic, and metal. With the right film, ink, and print contrast, they scan fast, resist moisture, and cut rework on the shelf.

Retail teams want products to scan fast, look clean, and meet shelf rules. Paper labels can cover design, peel at edges, or leave sticky marks. That hurts scan time and shelf appeal. Transparent barcode labels solve these pain points for brands and stores that care about speed, beauty, and cost.

Clear film blends into bottles, jars, and boxes. The pack design stays visible. Codes still scan well when you use high contrast art and the right print method. For teams that manage many SKUs, this can mean fewer voids, fewer returns, and fewer line stops. In short, clear barcode labels bring order to busy shelves. They also support simple, modern looks that shoppers like. In this guide, you will see how these labels help retail teams hit scan rates, protect branding, and control spend.

What Are Transparent Barcode Labels?

Transparent barcode labels are clear film stickers that carry UPC, EAN, or QR codes without hiding the packaging design. The film, often BOPP or PET, fades into the surface, so art and product stay visible. A strong, clean adhesive keeps the code flat. With the right ink and contrast, scanners read them as quickly as paper labels.

Key Characteristics Transparent Barcode Labels

Clear label performance depends on film type, adhesive, ink system, and layout. When these work together, you get fast scans and a clean look.

- Film options include polypropylene, PET, and vinyl for moisture resistant labels and abrasion resistant stickers.

- Adhesives range from permanent to removable for glass, HDPE, and coated cartons.

- Print methods include barcode printing by thermal transfer, flexo, and digital.

- Contrast planning sets dark bars on a light field for strong PCS.

- Layout protects the quiet zone and code size for quick reads.

- Finishes include overlaminate or varnish that resists smudge and wipe downs.

- Compliance support covers GS1, UPC transparent labels, and retail inventory labels.

When you match film, adhesive, and print setup to the pack, your scannable transparent barcodes stay clear, flat, and easy to read in store and in the warehouse.

The Core Benefits of Transparent Barcode Labels for Retail

In inventory management, barcode labels are unquestionably the unsung heroes and provide retailers and brands with an essential tracking system. The use of clear labels helps retailers keep products neat and on brand while meeting scan and shelf requirements. Also, they allow you to place the code anywhere you want. This reduces returns, rework, and checkout lines.

Here are 10 ways transparent barcode labels help your team every day.

#1 - Aesthetic Integration

In a crowded aisle, retail packaging must look clean. Using clear barcode stickers ensures that the design is not blocked by cartons, jars, and bottles. While meeting scanning rules, you maintain the minimalist look of the packaging. The edges of paper labels make this difficult.

Using custom transparent labels helps you match gloss or matte levels to the pack. You can add a soft-touch varnish or a high-gloss coat for glassy items. The barcode appears there without drawing extra attention. The polished fit of luxury products can support premium pricing and repeat purchases for these labels.

#2 - Product Visibility

Food jars, serums, and sprays often sell best when shoppers can see the product. Clear film keeps content visible and makes clear product labels look neat. The brand art and product color show through, while the barcode stays easy to read.

Many retailers now want brand transparency labels. With a clear code, you can show ingredients and origins without visual clutter. This is handy for clean-beauty SKUs and cold drinks. You get the data you need on pack and still keep the fresh, open look shoppers like.

#3 - Enhanced Shelf Appeal

When there is a mess in product rows, why would shoppers stay there so they move on. Paper shelf labels can crease or curl. Transparent film sits flat and keeps edges low profile. That makes the full set look neat and premium. The result is better first glance value and fewer damaged returns.

Clear film also pairs well with foil, emboss, and spot varnish. If you sell tea tins or glass tonic bottles, custom barcode stickers on clear film let the base pack shine. Many buyers judge quality in seconds. A clean code that blends in can raise trust at that moment of truth for retail packaging solutions.

#4 - Flexibility in Placement

Not every packaging box has a perfect white spot for a code. Clear material gives your brand more options. You can set the code on curved glass, plastic bottles, or coated board and still keep art visible. This helps when you run late-stage barcode stickers for retail during kitting or co-packing.

If your brand ships products in multiple markets, you can vary code placement by region without new base art. The use of custom transparent labels provides a single global solution. In this way, changeovers and short runs can be sped up. Additionally, it reduces the risk of a change in rules for a buyer group or chain.

#5 - Durable Protection

There is a tough environment for labels in stores. The environment is cold, hot, spilled, and wiped. The BOPP and PET films that are clear are used as label protectors in the retail industry. They resist water, oils, and cleaners. This prevents paper fuzz and edge lift and keeps bars sharp.

You can add a clear overlay to build durable barcode stickers that survive coolers and back rooms. For high-touch packs, choose polypropylene (PP) clear labels with a scuff resistant varnish. Your codes stay crisp through the full path, from DC to aisle, with fewer reprints.

#6 - Reduced Residue & Waste Perception

Shoppers dislike gummy edges and torn paper on products. In the end, these things make products unappealing, which results in decreased sales. Clear films peel cleaner and leave less sticker residue than many paper stocks. That helps when stores need to remove promo codes or swap asset tracking labels on loaner items.

Clear waste also looks lighter in bins. A retail team who sees fewer torn white scraps will be less likely to make a mess. These types of small things matter a lot. Keeping the back room clean reduces stress and accelerates the completion of tasks. Clean removal is a simple way to help staff and keep morale up.

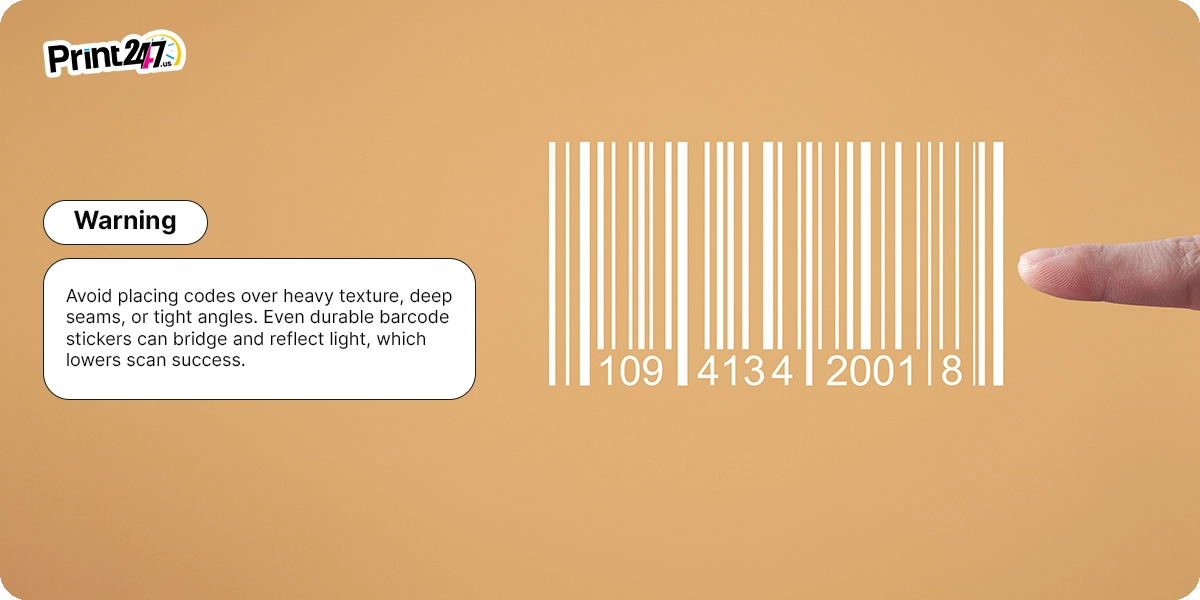

#7 - Optimized Scanning Performance

Good scans need contrast, quiet zones, and flat codes. Transparent barcode labels can do all three when planned well. Use a light background with dark bars and clear margins. With these things, scannable clear labels scan as fast as paper in POS and DC lines.

For harsh spots, use thermal transfer labels with resin ribbons for deep, crisp bars. If you need fast on-demand runs, digital print works well too. Always check retail targets and test with store scanners. A quick pilot can save many hours later.

#8 - Brand Consistency

Brands spend a lot on look and tone. Brand consistency builds trust and recognition. Clear labels support that work. You can keep color palettes, textures, and finishes in view while meeting barcode rules. That makes line reviews smoother and protects retail space wins.

Using custom transparent barcode labels, you can control the sheen and tint across all product lines. The labels align regardless of whether you use matte jars or glossy PET bottles. Buyers see one clear family on the shelf. By doing so, planograms and resets can move more quickly with fewer tweaks.

#9 - Security and Tamper Evidence

Combining tracking and authentication capabilities with tamper evidence is an art. Clear materials can carry slits or void patterns that show if someone lifts the label. This helps with seal points on caps and lids. You can pair the code with a small clear tab for simple tamper clues that do not block art.

For goods with a higher level of risk, QR codes should be combined with batch data on clear labels. There is a possibility of checking returns, and there is a possibility of tracking lots using systems. It builds trust between stores and shoppers without cluttering up the front panel with bulky seals and stickers.

#10 - Cost Savings

Transparent barcode labels are helpful in cost savings. Direct printing on packaging can cost thousands of dollars. Clear labels provide a cost-efficient alternative to direct printing on packaging. It means one printing mistake and the entire container is wasted. You can tackle this problem with these transparent labels. Reducing errors and improving efficiency means fewer resources are spent on correcting mistakes.

Moreover, clear labels have a longer life expectancy, so they save you money. This is because they are inherently durable, so they do not require any additional lamination or protective coating. Therefore, less material is used, resulting in a cost savings.

Real-World Applications of Transparent Barcode Labels in Retail

Transparent barcode labels are used in the retail industry due to their aesthetic advantages and practical functionality. They bridge the gap between high-end product appearance and operational efficiency.

Clear codes help many categories, from beauty to beverages. Here are some common use cases where a clear, neat look matters as much as scan speed and data accuracy.

Cosmetics and Personal Care Products

In the beauty industry, transparent barcode labels are perhaps most prevalent, since a "no-label" look is an important part of premium branding. Serum droppers, lip oils, and toners need clean bottles. Clear codes keep the luxe look while meeting GS1 rules.

- Great for glass and PET where art is key

- Works with luxury product labels and fine finishes

Using transparent stickers with crisp black bars creates a sense of texture and shade for buyers. The beauty aisles are filled with testers and wipes, so label protectors are a good idea to protect your labels.

E-Commerce and Warehouse Management

In the process of shipping online orders, they pass through bins, totes, and racks. Transparent barcode labels stick to plastic and metal without flaking.

- Ideal for asset tracking labels on gear

- Clean removal helps re-use containers

In the distribution center, scannable transparent barcodes speed picks and cycle counts. For on-demand work, keep blank clear rolls and print with thermal transfer labels to match batch needs.

Food and Beverage Industry

A transparent sticker is commonly used in beverages and gourmet foods. It highlights freshness and the artisanal quality of the items. Cold drinks, sauces, and condiments sit in wet coolers and ambient shelves. Clear film resists moisture and keeps edges sealed.

- Strong choice for moisture resistant labels in chill cases

- Pairs with UPC transparent labels for POS speed

With clear product labels, shoppers see color and clarity in the jar. You should choose polypropylene clear labels with freezer grade adhesive for deep chill and light condensation.

Luxury Goods and High-End Retail

For luxury and high-end retail products (like laptops, audio equipment, or small appliances), labels should be discreet and provide essential High-end items live on small design details. Clear codes avoid visual noise and let textures show.

- Supports foil, emboss, and matte packs

- Fits brand guidelines that limit visible stickers

With brand transparency labels, you add codes for POS and returns without spoiling the look. If you set a small white block under bars, scans stay fast even on dark packs.

Final Thoughts

Transparent barcode label solutions are more than a trend. Their solutions solve challenges for buying teams, packaging leads, and store operations on a daily basis. They keep art in view, codes flat, and scans quick. They also control cost when SKUs change often. With opaque barcode labels, you can keep shelves cleaner and lanes moving faster without having to create new base art.

Do you need assistance choosing the film, adhesive, and print method? Take advantage of Print247's services. As the leading packaging supplier based in Rosenberg, Texas, we offer free design support, eco-friendly materials, fast delivery, and physical samples. Our printing and packaging expert team creates custom, transparent barcode labels and durable barcode stickers that match your SKU list and retail requirements.

Interested in seeing results in store with our printing products? Get in touch with Print247 today.

FAQs

What is the lifespan of transparent barcode labels?

The average lifespan of transparent barcode labels is 1 to 5+ years. These stickers are made from reliable polyester or polypropylene. Their lifespan depends on the printing method, environmental condition (UV, moisture), and protective coating.

Are transparent barcode labels a good fit for curved bottles and jars?

Yes. Flexible films like BOPP and PET conform to curves when paired with the right adhesive. Keep the code over a smooth zone and respect the quiet margins. It makes it easier to read clear scannable labels on busy counters and in coolers since this setup allows them to be read quickly.

How do I keep contrast high on dark or metallic packaging?

Place the barcode on a light patch, use a white underlayer, or choose high-opacity black. Test with retail scanners before full run. This simple step helps clear barcode labels scan well even on rich colors or foil packs.

What print methods work best for clear retail codes?

Barcodes should be placed on light patches, with white underlayers, or with high opacity black. Perform a test run with retail scanners before going live. In this simple step, clear barcode labels will scan well even on foil packs or rich colors.

Can I add QR plus UPC on the same clear label?

Yes. The UPC is often accompanied by a QR code. Make sure both quiet zones are clean and avoid crowding. By using custom transparent labels, you can organize codes neatly while still maintaining minimalist packaging.

Do clear labels hold up to cleaners in beauty and grocery aisles?

Choose stickers that have an overlap that protects against abrasion. Whether you use PET or thick BOPP materials, you won't have to worry about smudges or shelf wipes. Protective label holders for retail display bins keep items in good condition when it is used daily.

What if I need eco options for clear barcodes?

Ask about eco-friendly barcode labels with thinner films, wash-off adhesives, or recycled liners. You can still get strong scans and good shelf life. Match the eco spec to your pack and supply chain.

Is BOPP the only option for clear barcode film?

No. PET and vinyl films are also common. BOPP is popular for value, clarity, and crack resistance. PET brings heat strength. Pick based on fill temp, squeeze, and store care. All work with scannable clear labels when contrast is planned well.

.jpg)

.jpg)

.jpg)