What is Cardboard Packaging? Types, Benefits and Uses Explained

.jpg)

In the packaging industry, cardboard is a broad term. Cardboard packaging is a paper based packaging material made from layered paper pulp that brands use for boxes, cartons, and retail displays. It is thicker and more durable than standard writing paper. It supports all types of printing formats and is an eco-friendly choice.

Globally, over 72 million tonnes of cardboard are produced annually, of which 90% is used for product shipment. If you’re running a business that requires packaging, then you know the pressure. You have to deal with costs, damages, sustainability goals and still keep your product premium on the shelf. Cardboard feels simple, yet there are many grades, flutes, and board types that can confuse even seasoned buyers.

In the coming sections of this blog, you will learn about what cardboard really is, what cardboard is made of, how corrugated fiberboard works, and where each type fits best in your product line. Our goal is to talk like a packaging partner, not like a textbook, so you can provide your printer or box supplier with information in confidence.

You will know which cardboard stock to use for folding cartons, which corrugated cardboard sheets you need for heavy loads, and how to match board grade to your budget and risk level.

Let’s start now.

Key Takeaway:

- Cardboard packaging comes in paperboard and corrugated fiberboard grades.

- A stronger cardboard uses liners plus flutes for higher packaging durability.

- Different corrugated board sheets suit retail, shipping, or industrial loads.

- Cardboard supports custom packaging solutions and strong branding.

- Most grades come from paper pulp material and are widely recyclable.

- The right cardboard choice lowers damage, freight costs, and returns.

- Cardboard helps brands hit environmental impact and cost targets together.

What is a Cardboard?

Cardboard is a versatile and stiff paper based material. It is made from one or more pulp layers of paper pulp material that are pressed and dried into a thick board. Cardboard is essentially an umbrella term for two very different materials.

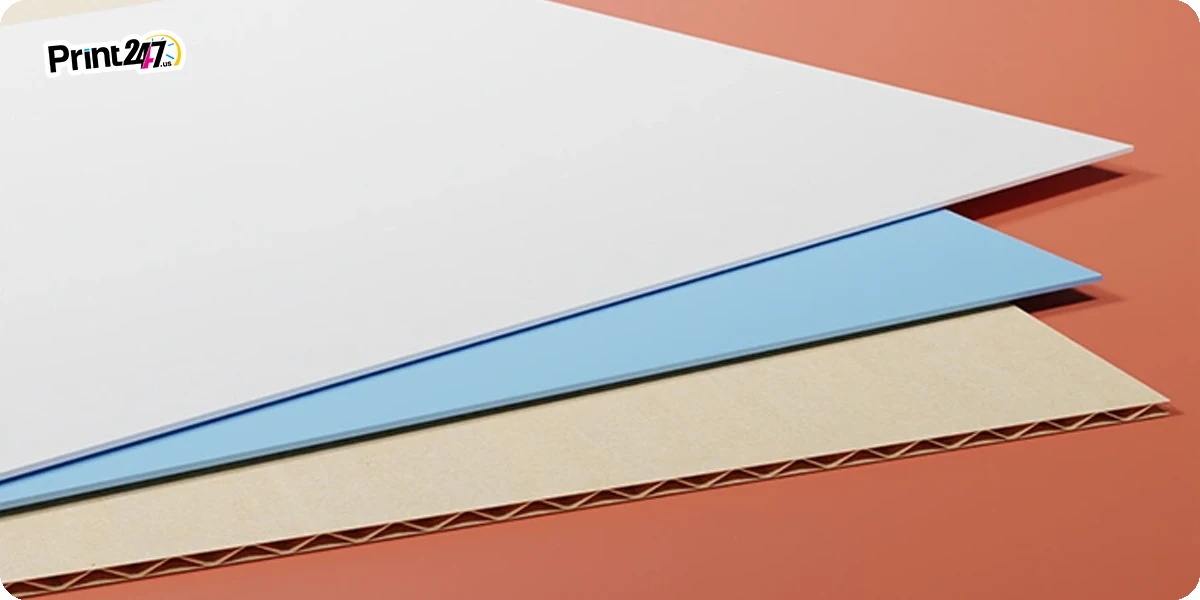

Most people use the word “cardboard” for any carton or box, but in packaging, we split it into two big groups. One is a flat paperboard that is used for folding cartons. It is a single solid layer of thick paper. It is usually 0.010 inches (10pt) thick or more. The other one is corrugated fiberboard that is used for shipping and transport packaging. It consists of a wavy inner layer called fluting and glued between two flat outer layers called liners.

Both types come from the same basic source: trees or recycled paper that are turned into shock-resistant material using controlled fiber blends.

The cardboard boxes market was valued at US $124.92 billion in 2025. Now it’s expanding at a CAGR of 4.1% and expected to reach US $186.70 Billion by 2035. This trend is driven by accelerating e-commerce volumes, which account for nearly 45% of global box demand, and by rising eco-friendly mandates. Source: Towards Packaging

What Are Different Types Of Cardboard in Packaging?

There are two main types of cardboard packaging. The first is paperboard, often called boxboard or carton board, used for cosmetics, food sleeves, and pharma packs. The second is corrugated fiberboard, built from liners and flutes, used for shipping cases and heavy-duty boxes.

Type A: Paperboard (Folding Cartons)

Paperboard is a smooth, single layer board used for branded folding cartons and sleeves. In terms of strength, it is in the middle of boxboard versus corrugated. It is thinner and sleeker than a shipping board, yet stiffer than regular paper. This makes it ideal for unit cartons, secondary packaging, and small POS units. Paperboard often carries high-end printing, foil, and coatings while still staying in the lightweight packaging category that saves freight.

Paperboard is further categorized into two types. One is a standard paperboard that is slightly thinner and the other is a matboard that is a thicker and more rigid form of paperboard.

Here’s the comparison table between standard paperboard and matboard.

Type B: Corrugated Fiberboard (Shipping Boxes)

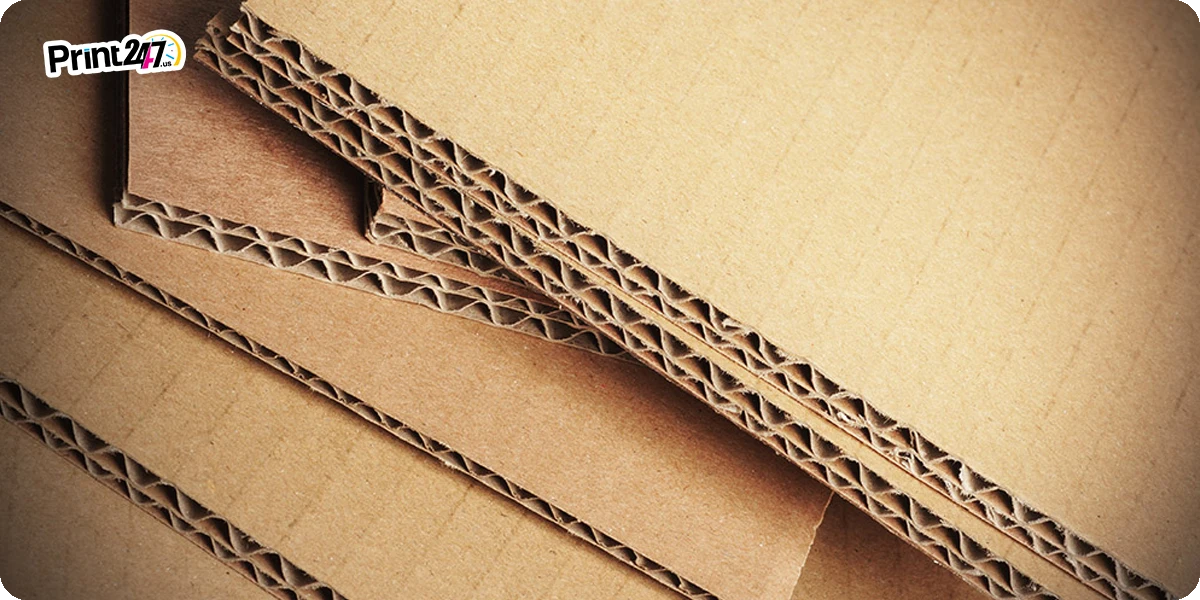

Corrugated fiberboard is another type of cardboard. It is a multi-layer board made from flat liners and wavy flutes for strong shipping boxes. This is the material most people picture when they think of a cardboard box.

Two or more flat liners sandwich a fluted cardboard medium to form a strong, impact-resistant board. The final corrugated board sheet can then be cut, creased, and glued into cases, trays, or die-cut mailers. Corrugated is ideal when you need transport packaging that can handle stacking, vibration, and long routes.

Here’s the comparison table between common flute types or flute grades.

Why Are Brands Switching to Cardboard Packaging?

Most brands are rapidly switching to cardboard packaging due to its cost-effectiveness, sustainability, and consumer perception. This shift is supporting a circular economy, reducing carbon footprints, and meeting consumer preferences for green packaging solutions. Cardboard packaging is a multipurpose solution that gives brands a balance of cost, strength, and sustainability across many SKUs.

Across retail, food, pharma, and industrial goods, more brands are moving from rigid plastics and wood to biodegradable boxes made from paper based board. Cardboard packaging fits most automated packing lines, prints well, and moves easily in existing recycling systems. It also allows tight size control, which means less air inside cases and lower freight cost per unit.

Here are some key reasons why brands are switching to cardboard packaging in the modern era.

Sustainability

The material that we use during the construction of cardboard packaging is made from renewable fibers and supports recycling systems. To start the construction of cardboard, first paper pulp material from managed forests or recovered paper streams is gathered. Now, many board mills are using a mix of virgin and recycled fibers to balance performance and environmental impact. Reporting on cardboard recycling rates is easier than on mixed plastic waste for brands with ESG targets.

Cost-Efficiency

Cardboard has become a center of packaging portfolio for many brands, not only due to cost-efficiency. It’s all due to its unique strength-to-weight ratio. When we compare it with plastics and wood, it is light, strong, and relatively low in material cost. Furthermore, using recycled paperboard can reduce 20% more costs.

Flat-packed cardboard minimizes warehouse space and freight costs for your plants. For many brands, switching from overbuilt plastic to tuned corrugated fiberboard sheets can reduce packaging cost per unit and cut damage rates at the same time.

Brand Protection

Brand protection is a key benefit because the right material keeps products safe and brand image intact across the full route. Properly chosen corrugated board sheet grades act as shock-resistant material, especially when combined with smart inner protective liners and dividers. This prevents crushed corners, broken seals, and scuffed labels that can hurt perception at delivery. Cardboard also supports strong print, so warning icons, lot codes, and branding stay legible on pallets, in hubs, and at retail. Matching flute profile and liner weight to your product protects both contents and your brand promise.

What Are Common Uses and Applications of Cardboard Packaging?

Cardboard packaging is a versatile and cost effective option for retailers, e-commerce sellers, and industrial shippers. They all can benefit from this packaging solution at the same time. The reason is that it comes in many calipers and grades, cardboard works for small folding cartons, medium mailers, and large bins. It can be die cut, glued, folded, and printed in one pass. It also pairs well with printing when you need large cardboard sheets for POP units and retail displays.

Using cardboard for everything from simple mailers to complex multi-part kits, you can build a complete packaging system with just a few core board grades.

Here are some uses and applications for cardboard packaging.

E-Commerce and Shipping Solutions

E-commerce and shipping solutions are among the largest users of corrugated cardboard because parcels must survive rough handling. Online orders face conveyors, sorters, and multiple van rides. Here, corrugated sheet, cardboard and tuned corrugated fiberboard sheets matter more than glossy print.

You want a consistent board caliper, tested ECT or BCT values, and inner protective liners where needed. Many brands now move to right-sized mailers and ship-in-own-container designs that still rely on durable cardboard, which reduces voids and air. Strong, well-designed shippers lower claims and help platforms trust your brand.

Retail and Consumer Packaging

Retail and consumer packaging is where paperboard shines by balancing appearance and structure. For shelf packs, cardboard sheets are converted into sleek folding cartons that can run on automated packing lines. Here, board smoothness and whiteness matter because they affect how your graphics print.

Printing on cardboard sheet large sizes is also common for in-store signage, shelf strips, and free-standing retail displays. By choosing the right coatings and finishes, cardboard packaging can handle scuffs and maintain its clean, bright look, which matches your brand.

Industrial and Transport Packaging

The use of double walls and triple walls of corrugated board is common in industrial and transport packaging for the protection of heavy and bulky products. A high-quality corrugated board sheet is often used as an alternative to wood for pallet bins, drum overpacks, and automobile components.

With a triple-wall, tall loads are more rigid and stack more securely while still being easier to handle than timber. Inner cardboard sheets and pads separate layers and spread the weight. The fiber-based packaging can also reduce tare weight and simplify customs procedures since everything stays within a single fiber family.

Creative and Non-Traditional Uses

In recent years, designers have experimented with cardboard for fixtures, brand experiences, and non-traditional uses. The use of large cardboard sheets is becoming more popular for event booths, short-term kiosks, and 3D shapes that would normally be made of plastic or metal. These creative cardboard products include school kits, promotional mailers, and reusable display trays. In many cases, these pieces still flatten for shipping and then join regular cardboard recycling streams.

How to Choose the Right Cardboard Packaging?

The right cardboard packaging choice is a step-by-step process that matches your product and brand goals. Ideal cardboard packaging requires a strategic balance between structural integrity and logistical efficiency. When the wrong material is chosen, it can result in costly product damage and unnecessary shipping surcharges.

The steps below help you brief suppliers and compare quotes in a structured way.

Step 1: Define Product and Route Risks

To choose the right cardboard packaging for your brand, first, it is important to examine the product’s risk profile and shipping route from the plant to the customer. For that, list product weight, fragility, and any sharp edges or pressure points.

The journey begins with the pallet. Next, it goes to the hub, then to the store, and finally to the customer's door. Consider humidity, temperature swings, and the number of touches. For high-risk routes, triple-check your need for shock-resistant material and ask for tested corrugated cardboard sheet grades instead of generic “standard board.”

Step 2: Match Board Type to Use Case

In the next step, you need to determine which type of box you need based on the role they play in your system. Primary display packaging, such as a cosmetic unit carton, usually calls for paperboard or SBS.

Outer shipping cases need corrugated fiberboard sheets with the right flute and liner weight. In some cases, pallet bins or bulk packs require double-wall or triple-wall insulation. It prevents overbuilding small boxes and underbuilding master cartons when there is clear separation.

Step 3: Identify Strength, Not Just Thickness

Apart from the thickness of the cardboard box, strength is also an essential factor in this journey. The reason is that strength largely determines real-world performance. Thickness alone doesn’t guarantee durability. Not specifying it correctly can damage your product and increase shipping costs. Ask renowned packaging suppliers like Print247 to quote ECT or BCT ranges for corrugated board sheet options and bending stiffness for paperboard. Build a small table for your team linking product weight to board performance.

Step 4: Determine Print Method and Graphics Needs

The next step is to align the print method with your brand’s graphic needs and budget. High-end artwork may push you toward coated paperboard or premium liners. For outer shippers, simple flexo print or even custom printed labels can be enough. You should consult your print partner about resolution, coating, and handling when printing on cardboard sheets. When it comes to B2B channels, clean, clear branding and regulatory text are more important than special effects.

Step 5: Include Sustainability and End-of-Life Goals

The final step in choosing the right cardboard packaging is to factor in sustainability and end-of-life goals early in your product specification. In about two months, cardboard biodegrades. If your brand targets recyclable or biodegradable boxes, talk about fiber source, recycled material, and coatings at the start. Avoid plastic lamination unless truly needed. Ask how easily the final cardboard box enters common recycling streams in your key markets.

Why Cardboard Packaging Still Makes Business Sense?

Cardboard packaging is a practical, scalable answer for brands that need strength, print impact, and sustainability in one material family. For business to business teams, the situation is straightforward. Cardboard covers primary packs, shippers, and POS units with one core skill set. It works with all types of printing formats, runs on modern automated lines, and supports custom packaging solutions without locking you into one plant or region. It fits transport packaging rules around the world and makes it easier to meet both cost and ESG goals.

If you are looking for a reliable packaging supplier that understands real-life lead times, budget pressure, and quality checks, Print247 is the most suitable choice. With Print247, your team can receive free design support, free shipping on many orders, eco-friendly materials, fast production, and physical samples so you can test items prior to rollout.

From simple mailers to complex CBD packaging, you can source smart cardboard solutions with one experienced partner.

FAQs

Is cardboard packaging waterproof?

The nature of cardboard packaging does not make it waterproof. The reason is that it is made from paper pulp material that absorbs moisture. You can add coatings, wax, or liners for short-term water resistance, but this may affect cardboard recycling. For damp or chilled routes, discuss special barriers and liners with your supplier early.

Why is cardboard packaging better than rigid packaging?

Cardboard packaging is often better than rigid plastic or wood because it is lighter, easier to recycle, and cheaper to move. In contrast, rigid items consume volume even when empty, whereas flat-packed cardboard sheets take up less warehouse space and require less freight services. In many cases, tuned corrugated or paperboard will provide enough strength without being rigid.

What is the process of making cardboard for folding cartons?

To make cartons, pulp layers are pressed and dried into a smooth board and then coated with ink. A stable sheet of paperboard is obtained by controlling fiber mix, moisture, and caliper. A folding carton is then made by printing, cutting, and creasing cardboard sheets, ready for packing by converters.

How do I choose the right cardboard thickness for my product?

You choose the right cardboard thickness by matching product weight, stacking height, and route conditions to a tested board grade. Instead of guessing, ask for ECT or BCT data for each corrugated board sheet and bending stiffness for the paperboard. Run ship tests on samples to verify performance before a full rollout.

Is cardboard packaging sustainable?

Comparatively, cardboard packaging is highly regarded as one of the most sustainable options. Due to its renewable fiber content and recycling capabilities, it is a very environmentally friendly choice. In modern mills, biodegradable boxes and recycled-material boards are becoming more common. When placing an order, make sure the recycled content and certifications are accurate.

.jpg)

.jpg)

.jpg)