Lithographic Printing Explained: Process, Benefits, and How It Works for Packaging

.jpg)

Have you been on the lookout for Lithographic printing prospects? Well, Lithography, invented in 1796 by German author and actor Alois Senefelder, is a reasonable and effective way to print and publish artwork. It is a high-volume printing method that uses plates, water, and oil-based ink to transfer images to paper or packaging. It delivers sharp color, low unit cost at scale, and consistent results, which makes it ideal for cartons, labels, magazines, and marketing materials.

Even in a world full of digital presses and short-run solutions, lithographic printing holds great importance in packaging supply chains. If you manage a brand, handle procurement, or run operations, you care about print methods that control unit cost, protect brand colors, and run at scale without surprises. That is where litho, often called lithography or offset printing, still shines.

This blog is going to educate you about what lithographic printing is, how the lithography process works step by step, and why it still makes sense for folding cartons, sleeves, and other printed packaging. We are here to help your team determine which printing technique is right for your next printing run, ask better questions to packaging suppliers, and avoid costly mistakes on your next print run.

Let’s get started.

Key Takeaways:

- Lithography is a plate-based print method using oil and water to keep image and non-image areas separate.

- Lithography is ideal for high-volume packaging where you need sharp detail, fine text, and accurate brand colors.

- Alois Senefelder invented lithography during his efforts to reduce his publication costs.

- Offset printing moves the image from the plate to a rubber blanket, then to the substrate, which protects the plates and improves quality.

- Modern litho runs on aluminum plates, CMYK color separation, and automated pre-press systems that shorten setup time.

- Litho is more cost-effective than digital for long runs, but less flexible for variable data and on-demand work.

- Lithography artwork supports complex images, gradients, and photo-level detail across boxes, inserts, and catalogs.

- Litho can print on coated and uncoated paperboard, labels, and some synthetic substrates used in packaging.

- With good housekeeping and chemistry control, litho can support eco goals using low-VOC inks and recyclable stocks.

- For brands, litho’s biggest value is consistency across thousands or millions of packs.

What is Lithographic Printing?

Lithographic printing is a planographic print method where image and non-image areas sit on the same level of a flat plate. In simple terms, Lithographic Printing uses the natural push between oil and water to keep ink only where the image should be. A thin layer of water protects non-image zones, while oil-based ink sits on the image zones. The image is then applied to a rubber blanket and finally to the substrate. This is why modern lithography is also called offset printing.

Typically, this print technique is used for magazines, books, cartons, and other custom printed packaging where full color, detailed graphics, and tight registration are needed. It handles lithographic artwork, photos, and fine text well. It is probable that you are looking at a lithography print on a litho press when you see gradients and sharp logo edges on retail packaging.

A total of USD 501.36 billion was estimated for the global commercial printing market in 2024 and USD 598.06 billion is projected for 2030. Lithography accounted for 44.1% of the global market in 2024. (Source: Granview Research)

Types of Lithographic Printing

There are different types of lithography available. Generally, commercial and artistic forms of Lithography fall into three major groups that are commonly discussed in packaging and print discussions.

Here are the details of each type.

Traditional Stone Lithography

Traditional stone lithography is a manual method where the artist draws directly onto a limestone surface with greasy materials.

In this classic printing process, the stone is treated so that drawn areas attract ink while blank areas attract water. Afterwards, the inked stone is directly pressed against the paper by pressing it directly against it.

In most cases, this method is used for fine art lithographs and lithography artwork, and not for packaging. Despite its unique textures and collector value, this method is slow and is not suited to high-volume production.

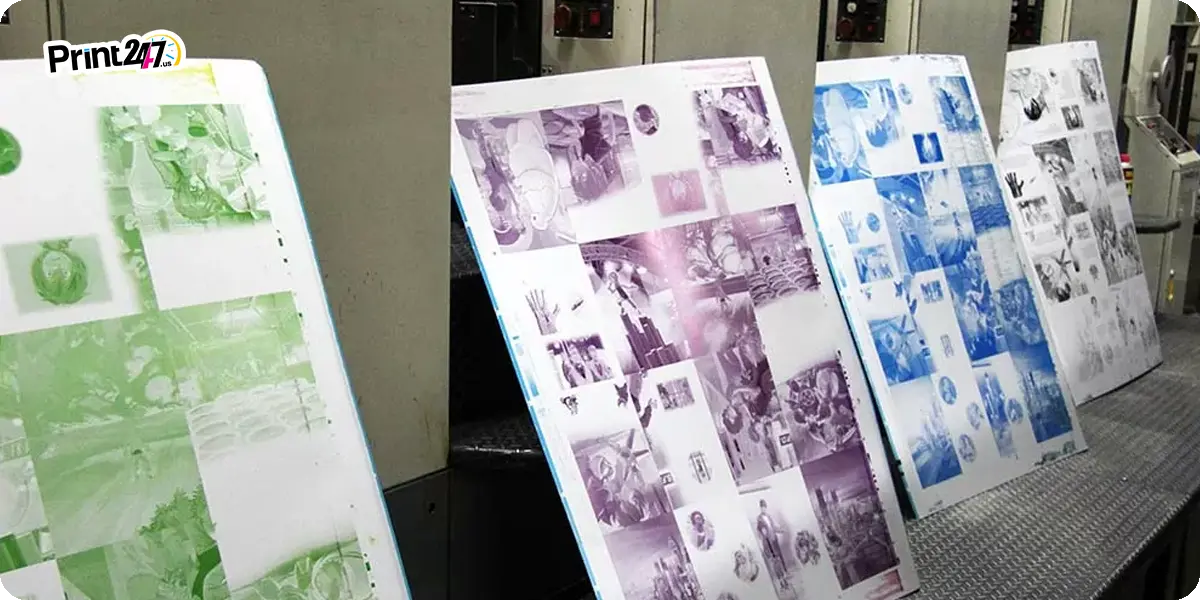

Offset Lithography (Modern Standard)

.webp)

The offset lithography process is a modern industrial form of lithography used for packaging, books, and marketing materials.

In this printing technique, the image is placed on a thin metal plate, then transferred to a rubber blanket, and only then to the substrate. The "offset" method protects the plate, allows for faster speeds, and supports a wide range of boards, coated and uncoated.

The majority of retail lithography examples you see are printed offset on cartons, labels, or sheets.

Waterless Lithography

Waterless lithography is a variant of modern lithography that uses special plates with silicone-coated non-image areas and no dampening water.

Rather than using water, the plate repels ink itself in non-image areas. It offers sharper dots, more stable color, and less paper stretching, which can be beneficial for lithography artwork and high-end product packaging.

It also reduces the need to manage fountain solution chemistry, though plate costs and process control can be more demanding.

How Does Lithographic Printing Work? (Step-By-Step Process Overview)

The lithographic process involves creating images, making plates, moving the ink to a blanket, and printing the finished substrate. Lithographic printing follows a clear chain from pre-press to finishing. Files are checked, plates are imaged, ink and water are balanced on press, sheets run through multiple units, and then cut and folded into the finished packaging you receive from your supplier.

The lithographic printing workflow is important because each stage affects color, cost, and lead time. A small file issue in pre-press or a plate problem on press can slow the entire job. Understanding the basic stages helps your team talk clearly with printers and spot risk early.

Here's a step-by-step lithographic printing process.

Step 1: Pre-Press Preparation: Image Creation and File Setup

In this step, your lithography artwork is reviewed for resolution, overprint settings, bleed, and dielines. Fonts are outlined or supplied, and barcodes are checked for size and quiet zones. The goal is to ensure the design will hold up at press speed and in real-life packaging use.

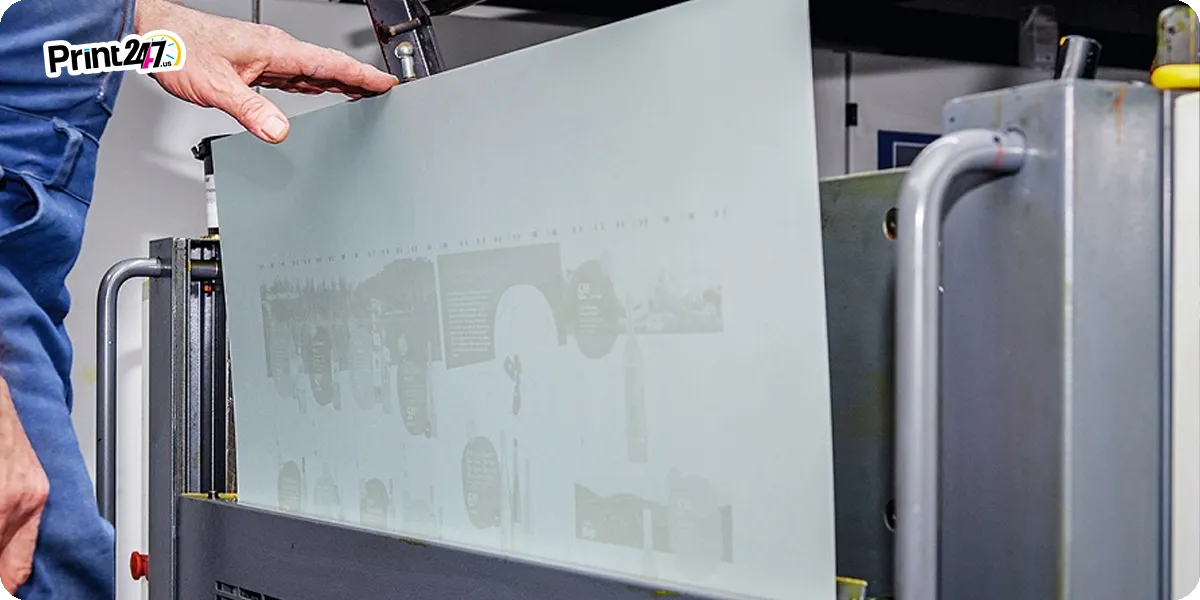

Step 2: Plate Making

Plate making is the process by which digital files become physical printing plates. Most modern litho operations use aluminum plates coated with light-sensitive layers. A platesetter uses a laser to image the design onto the plate, hardening or removing coating in image areas, depending on the system. Plates are then processed, gummed, and ready for press mounting.

Step 3: Mounting Plates on the Press

Mounting plates on the press is the step where prepared plates are wrapped around plate cylinders. Operators mount one plate per color unit, locking the plates in position with clamps and register pins. Accurate mounting ensures that each color aligns correctly, so that your text and images are sharp and not doubled.

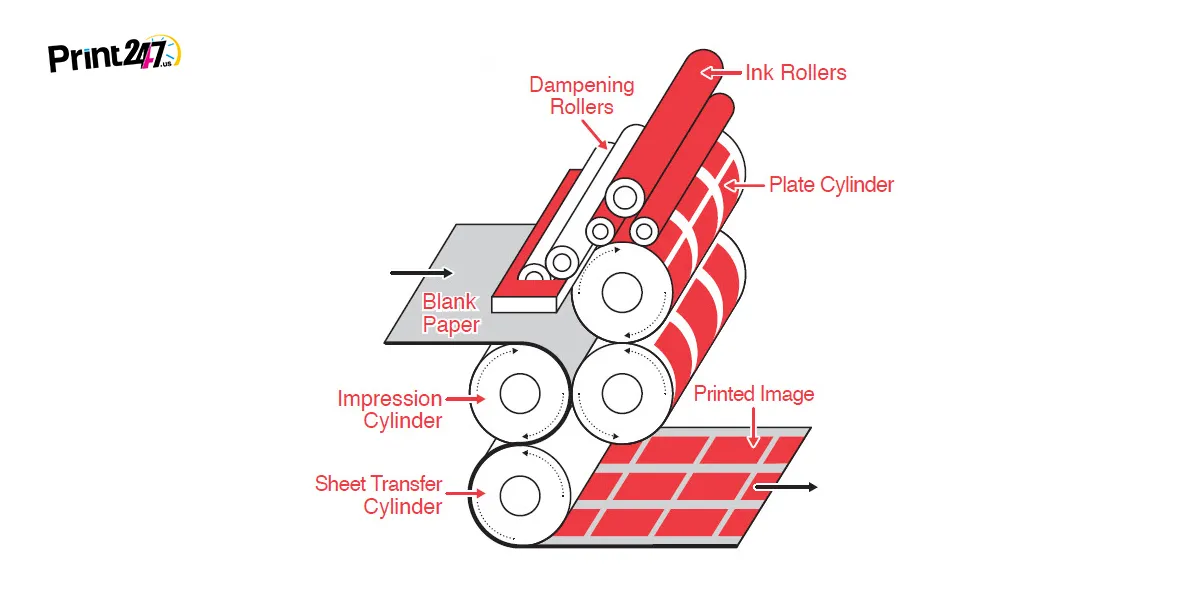

Step 4: Dampening System: Applying Fountain Solution

The dampening system is the part of the press that feeds water-based fountain solution to the plate. Rollers apply a thin, even film of fountain solution to non-image zones. This layer keeps those areas water-rich and ink-free, which is the heart of how Lithography works.

Step 5: Inking Process

The inking process in lithographic printing is where ink travels from the ink fountain through rollers to the plate image areas. Ink passes through a train of rollers that smooth and meter the film thickness. The ink only sticks to image zones, since those areas are not wet. Stable ink feed is essential for smooth solids and even tints in lithography print work.

Step 6: Image Transfer: From Plate to Blanket to Substrate

Image transfer is the point where the printed image moves from plate to blanket and from blanket to substrate. The plate first gives the inked image to the rubber blanket. The blanket then presses the image onto the sheet or web as it passes through the nip between the blanket and impression cylinders. This two-step action helps manage rough or uneven surfaces and protects the plate.

Step 7: Printing and Drying

Printing and drying are the stages where sheets receive the image and then stabilize for handling. Sheets pass through color units, one for each CMYK and spot color. After printing, the ink must dry through absorption, oxidation, or UV curing before the job moves to cutting or further processing.

Step 8: Post-Press Finishing

Post-press finishing is where printed sheets turn into final products like cartons, sleeves, and inserts. After drying, the sheets move to die-cutting, folding, and gluing lines. Quality checks at this stage catch issues like cracking, misfolding, or color variation before packs reach your co-packer or warehouse.

What Are Some Advantages of Lithographic Printing?

There are several advantages to lithographic printing that make it a smart choice for long-term packaging and print programs. Printing with litho is a great option when you need high image quality, stable unit costs at volume, and reliable repeatability across multiple print runs. Compared with other methods, it hits the sweet spot between speed, cost, and visual quality for many packaging categories.

High-Quality Output and Resolution

High-quality output and resolution are core strengths of lithographic printing. It manages small types, fine lines, and smooth gradients better than many other analog processes. This makes it a strong match for cosmetics boxes, pharma inserts, and any lithography artwork that uses photos or soft tonal areas on board or paper.

Cost-Effectiveness for High-Volume Runs

Cost-effectiveness for high-volume runs is a major reason brands keep using lithography. While plates and setup take time and money, unit cost drops sharply as run length grows. For regional or national launches with many pallets of packaging, litho often gives a lower price per piece than digital or smaller analog systems.

Versatility with Substrates

Versatility with substrates is another benefit of offset printing. Litho presses can run many grades of paperboard, text stocks, and label materials, including coated, uncoated, and some specialty stocks. Using this flexibility, you can create lithography examples ranging from cereal boxes to premium gift packaging.

Consistency in Large Print Tasks

Consistency in large print tasks is the reason many global brands rely on litho as a standard. With lithographic printing, colors and densities can remain stable for thousands or even millions of sheets once the press is centered. The control of logo colors and the quality of lithography prints is tightly controlled and managed with plate-based tools and ink management.

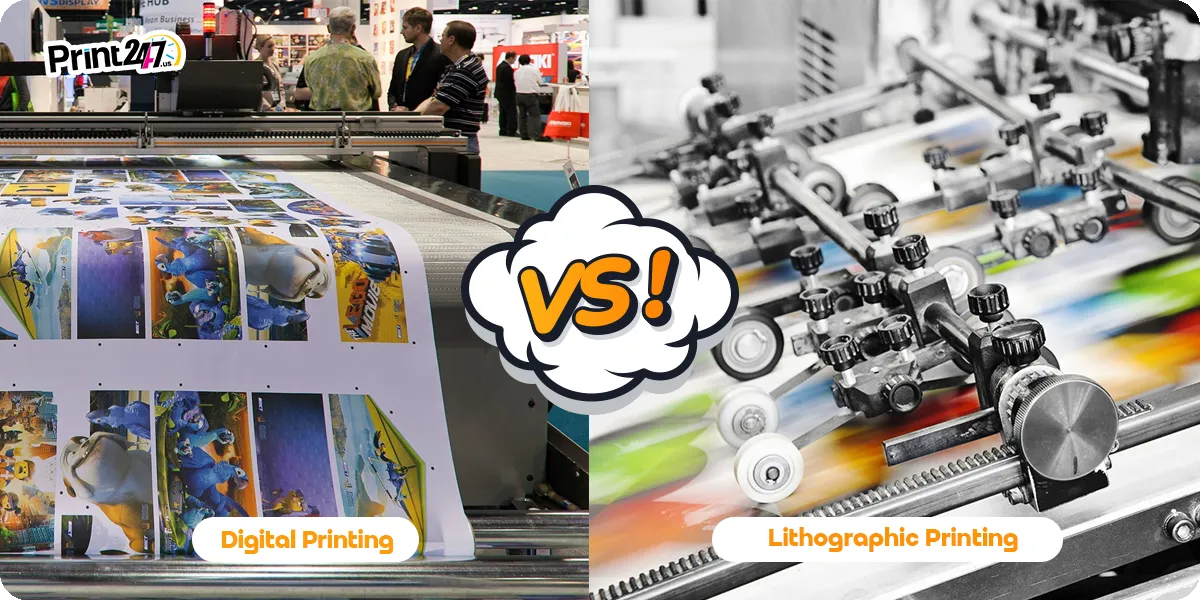

Lithographic Printing vs. Other Printing Methods

Lithographic Printing vs other printing methods is a common comparison that helps buyers match process to job needs. Each method has its own setup cost, quality range, substrate fit, and best use case. For many brands, the right answer is not one method but a mix, with litho handling core high-volume work while other printing methods manage short runs or special materials.

Lithographic Printing vs. Digital Printing

Lithographic Printing vs digital printing is the most common question from teams who want both speed and quality. Litho is strong for long runs with fixed artwork, while digital printing excels at short runs, personalization, and frequent design updates. For growing brands, it is common to start on digital and then move to litho once the forecast and volume stabilize.

Here’s the comparison table for lithographic vs. digital printing.

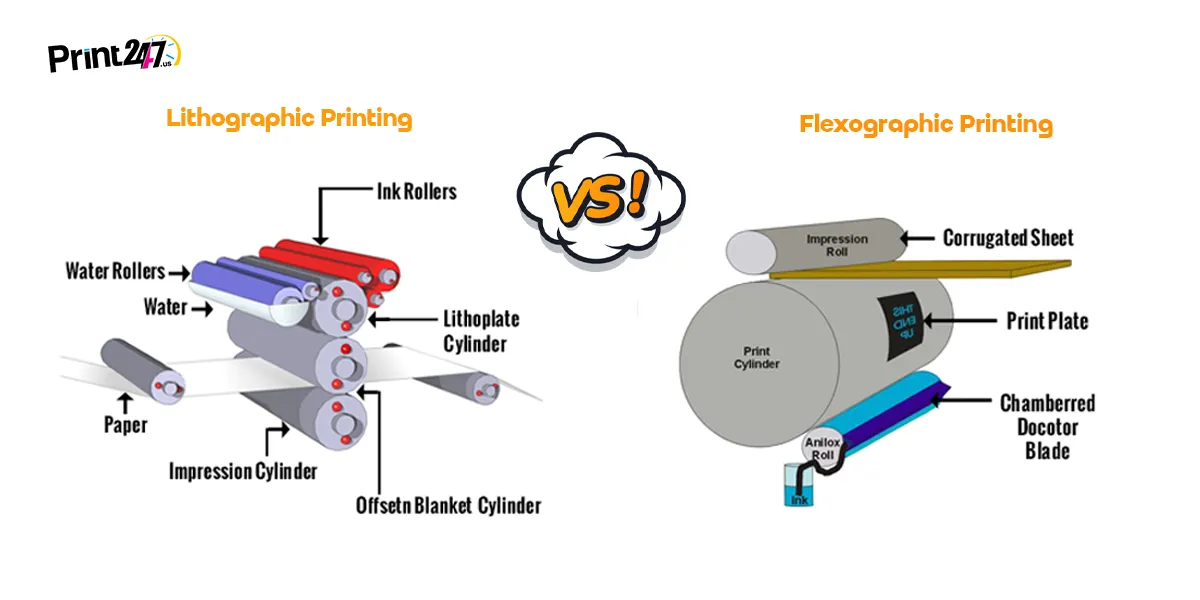

Lithographic Printing vs. Flexographic Printing

It is vital to understand the difference between lithographic and flexographic printing for folding carton and label buyers.

Litho provides fine detail and smooth images, while flexo provides flexible packaging, labels in rolls, and very long runs on websites. The right choice depends on substrate, run length, and print quality expectations.

Here’s the comparison table between lithographic vs. flexographic printing.

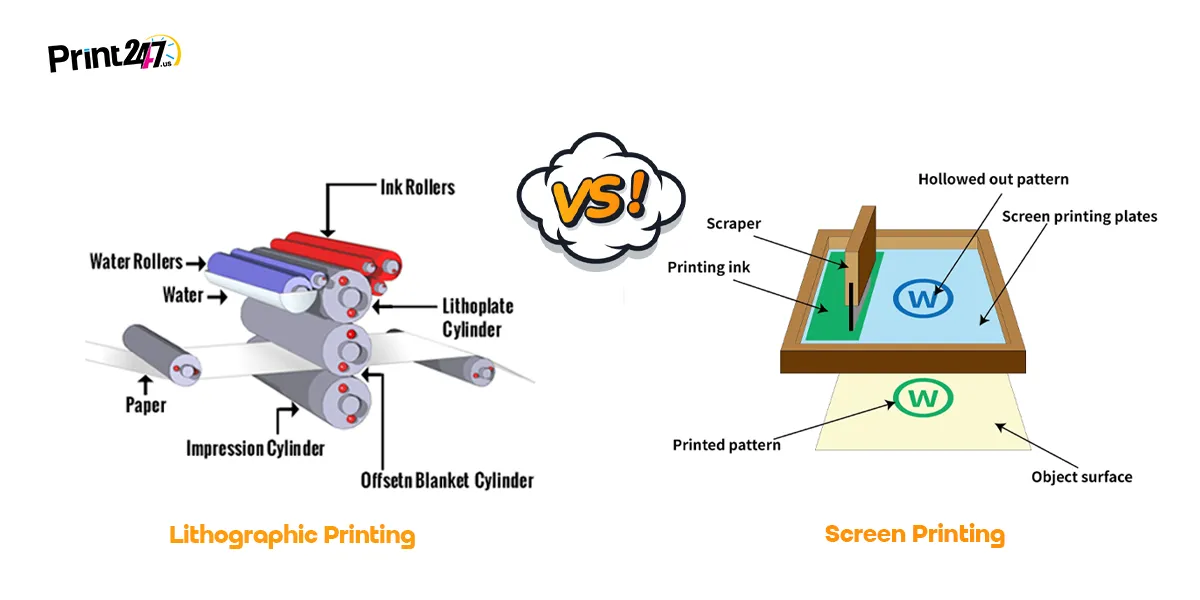

Lithographic Printing vs. Screen Printing

Lithographic Printing vs screen printing often comes up with premium finishes and special effects. Litho gives fast speed and fine detail for most of the job, while screen is often used for heavy white, metallics, or raised coatings. Many high-end packs combine both methods on the same piece.

Here’s the comparison table for lithographic printing vs. screen printing.

Lithographic Printing vs. Gravure Printing

Lithographic Printing vs gravure printing is relevant for very large consumer brands and long global runs. Litho uses plates with flat image areas, while gravure uses engraved cylinders. Gravure is powerful for ultra-long runs with stable artwork, but cylinder cost is high, which limits its use in many regional packaging projects.

Here’s the comparison table for lithographic vs. gravure printing.

Common Applications Of Lithographic Printing

The most common uses for lithography are product categories where lithography's quality and volume advantages are in line with business needs. In packaging and publishing, litho remains a workhorse for flat products made from paper and board. When you see consistent lithography print quality across nationwide packaging or high-page-count items, a litho press is often behind it.

Here are some common applications of lithographic printing.

Magazines and Newspapers

Magazines and newspapers are classic lithography examples in the world of publishing. Publishers use offset printing on web presses to print fast and at scale, keeping unit cost low while still offering photos, ads, and text that are easy to read. Although digital channels grow, many titles still rely on litho for physical copies due to the balance of speed and cost.

High-Volume Packaging (Cereal Boxes, Cosmetics)

.webp)

Lithography is well-suited to high-volume packaging such as cereal boxes and cosmetics cartons. To provide readable legal text, crisp barcodes, and strong shelf presence, folding cardboard converters run sheetfed litho presses on coated boards. Litho is well-suited to food, beauty, and personal care brands that live on retail shelves because it is capable of handling detailed lithograph artwork and CMYK images.

Posters and Maps

Posters and maps are traditional lithography examples that rely on large sheet sizes and good color control. Maps, on the other hand, require fine detail and legible type at small sizes, whereas posters require strong images and solid color fields. For event runs or public campaigns, lithographic printing provides quantities that justify the setup and plate investment.

Final Thoughts

Lithographic printing is a long-standing print method that continues to power large parts of the packaging world. For brands, the key benefit of this printing technique is control. Litho gives you reliable color, sharp lithography artwork, and predictable unit cost once your volume is high enough. Besides working across numerous board types, it integrates with coatings and foils, as well as slotting into existing folding, gluing, and finishing lines.

If you are planning a packaging project in the United States and need a local partner that understands lithographic printing in real production, Print247 can help. Print247 is a leading printing and packaging supplier in the US that provides free design support, eco-friendly materials, free shipping, and physical samples to help you sign off with confidence.

Our packaging manufacturing company allows you to create litho cartons, inserts, and branded pieces seamlessly, so your team can stay focused on growth rather than pressroom problems.

.jpg)

.jpg)

.jpg)