What Is Sublimation Printing and How Does It Work?

.jpg)

Sublimation printing is a renowned printing technique that transfers design elements onto the materials by using heat and pressure with a heat press machine. When heat is applied, the ink turns into microscopic particles and embeds onto the object's surface. The result is full color, long-lasting, and smooth to the touch, ideal for packaging, labels, and custom apparel printing.

Brands want color that pops, quality that is unmatched, and prints that will not be easy to peel or crack. All of these elements are crucial for enhancing brand perception. Sublimation Printing helps with all three. This process uses heat to move color into the surface rather than on top of it. Unlike traditional printing, it’s not stuck onto the surface, but it becomes a surface of the product itself.

For packaging staff, this can help samples, short orders, and promo lines look clean and pro. In this blog, we are going to explain what sublimation printing is, how it works, what you need, where it fits in packaging, and how it stands up against other print methods. We keep the concepts easy to understand and the steps clear, so your team can choose with confidence and act fast.

Key Takeaways:

- In sublimation printing, ink is turned into a gas by heat, which bonds to the surface.

- Works best on polyester fabric and polymer-coated hard goods.

- All you need is a dye sublimation printer, sublimation paper, and a heat press.

- Color is permanent, smooth, and resists cracking.

- Best for high-resolution designs and intricate designs with many colors.

- Ideal for short projects, samples, and fast changes.

- Cotton and uncoated paperboard are not good targets.

- For boxes, start with polymer-coated stocks or panels.

- Common items include sublimation blanks like coated tins, ceramic jars, and poly canvas bags.

- You can do an inkjet printer conversion for entry level setups.

- The Heat Transfer window is short, so workflow matters.

- Best mix of bright color and long wear for coated packaging parts.

- Great for full-color transfer and photo-like art.

- Keep files at print size with 300 DPI for clean edges.

- Use Heat-Resistant Tape and pre-press to remove moisture.

What Is Sublimation Printing?

Sublimation is a type of digital printing where a design is transferred from paper to the material using heat and pressure. With a heat press machine, the ink in the transfer paper reaches a gaseous state and bonds to polyester fabric or a polymer-coated surface. With it, you can print realistic, bright, and full-color designs, prints, and artwork. There is no raised ink layer. The result feels smooth, carries rich color, and holds detail well. This method is strong for high-resolution designs, photo work, and custom designs.

The Dye Sublimation market size in 2025 is USD 15.22 billion and is projected to reach USD 25.52 billion with a CAGR of 10.88%. Source: Mordor Intelligence

What is Sublimation Printing In Packaging?

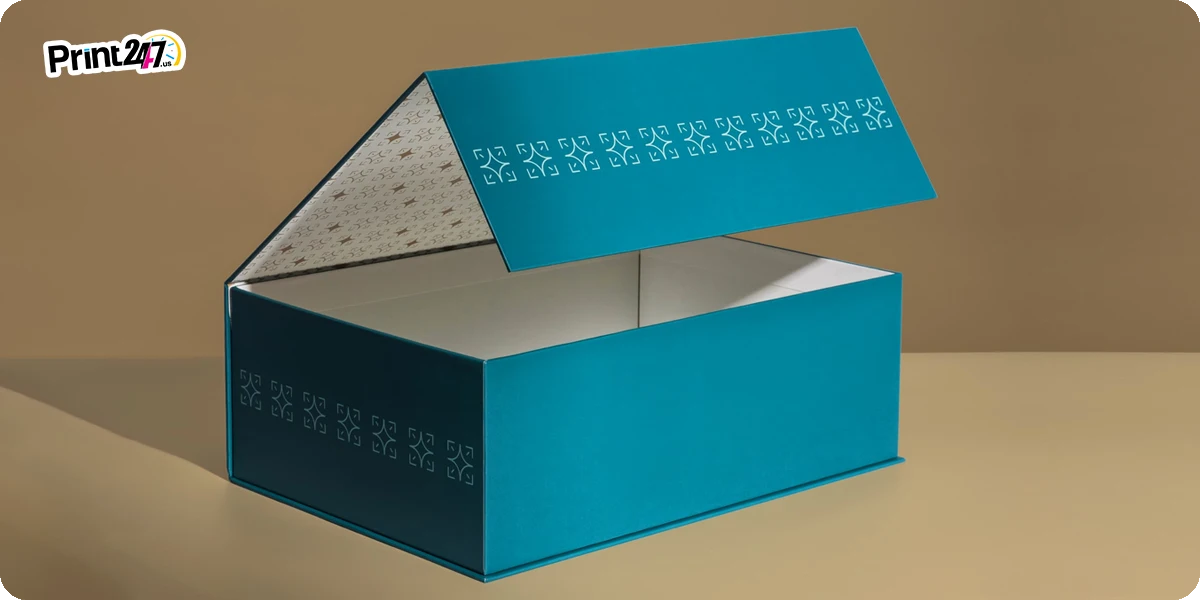

The concept of sublimation in packaging is the use of heat and pressure to print the design onto the packaging substrate. The process involves first printing a design onto a transfer paper, which is usually made of high-grade cellulose fibers. After that, this paper is pressed against the packaging material at high temperatures (180°C to 200°C). Typical products include coated box panels, tins, ceramic jars, and poly canvas bags. The print goes into the coating, so graphics look sharp and last through handling and shipping.

For packaging companies, dye sublimation helps in two ways.

- First, it supports short runs for new product tests.

- Second, it gives near photo color for gift sets, limited drops, and promo kits.

We recommend only using coated substrates. Uncoated kraft or cotton will not bond, so color will wash out or look dull. You can also combine sublimation transfer parts with other prints. For example, sublimate a coated lid for detail and pair it with a flexo printed shipper. This helps control cost while keeping the hero panel rich in color.

What Do I Need For Sublimation Printing?

It is important to have the right tools and components in order to create beautiful sublimation prints. These components work together and transfer the image permanently to the material. You need five parts to run sublimation printing in house. A printer that can handle dye sublimation, ink, paper, blanks, and a heat press machine or oven. Good files and clean preparation make the rest easy.

This is the complete list of what you need.

#1 - Sublimation Printer

Use a dedicated dye sublimation printer or do an inkjet printer conversion with refillable carts. A dedicated unit gives better uptime and color control. Pick a width that fits your largest item plus room for bleed. These printers come with all the essential software that is needed for perfect prints.

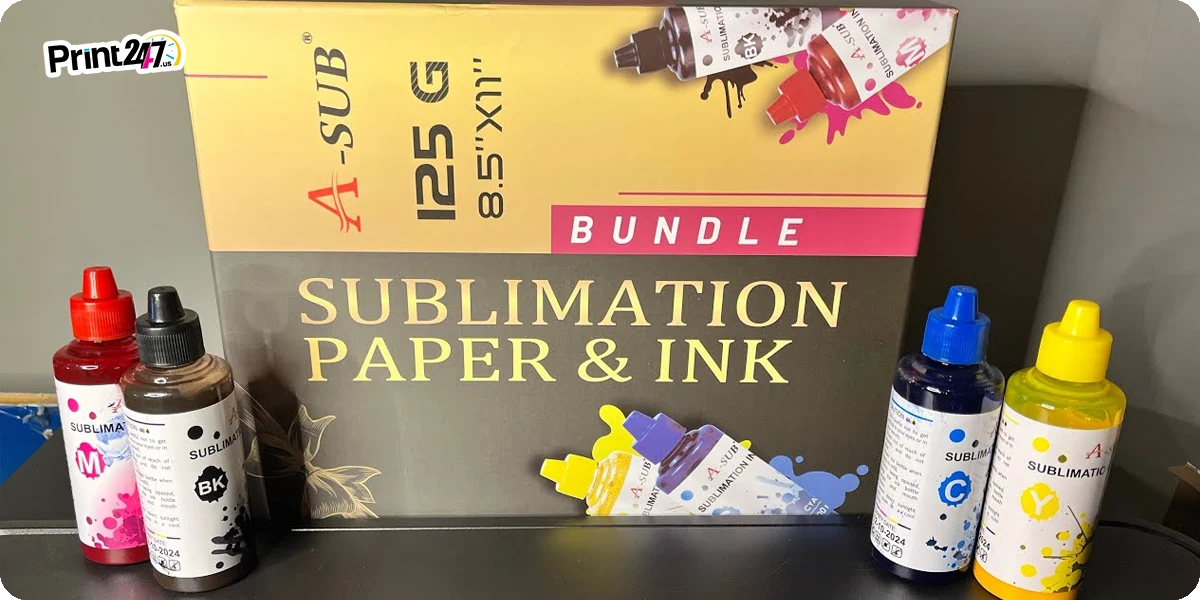

#2 - Sublimation Paper & Ink

Use sublimation paper made for your printer type. There are two types of paper: sheets and rolls, depending on the printer's specification. Pair it with dye-sublimation ink from the same brand to avoid clogging. Store both in a cool, dry spot. Keep sealed until use.

#3 - Sublimation Blanks

Sublimation blanks are items created to be used with sublimation transfers. Choose them with a polymer coat or polyester coat. Buy one or two test units first. Check size, shape, and coating quality. Keep a small buffer stock for rush orders.

#4 - Sublimation Oven Or Heat Press

Next, you will need a heat press or sublimation oven. A flat heat press handles sheets, panels, and textiles. Mug or tumbler presses help with round goods. For odd shapes, a convection oven made for heat transfer can work with wraps. Use a temp gun to verify heat.

#5 - Sublimation Designs

Sublimation designs are digital artwork files created with sublimation inks. The file type can be PNG, JPEG or SVG. Set files at print size with 300 DPI. Keep text above 6 pt where possible. Embed fonts or outline them. Save a master in PDF. For photos, use clean lighting and avoid heavy filters that can shift skin tones.

How Sublimation Printing Works? Step-by-Step Process

It uses a simple 3-step process that transfers artwork onto material. First, print your art with a dye sublimation printer onto sublimation paper. Then place that sheet on the coated item, secure with heat-resistant tape. After that, use a heat press to reach the needed heat transfer window. The ink goes to a gaseous state and bonds inside the coating.

The following steps will guide you through the process.

Step #1 - Print the Design

The first thing you need to do is send your file to a sublimation printer or a converted inkjet printer that uses dye sublimation ink. Print a mirror image on special transfer paper or sublimation paper. Keep files at 300 DPI at size. Use a solid vector where possible. For photos, keep sRGB color. Let prints dry before handling to avoid smudge.

Step #2 - Prepare the Print for Sublimation

Cut the transfer paper to the desired size and place it face down on the item. Tape edges with heat-resistant tape so it does not shift. It is recommended that you pre-press the material for five to ten seconds to remove moisture and wrinkles. Clean hard goods with a lint-free wipe. Any dust can show in the high-resolution designs.

Step #3 - Apply Heat And Sublimate!

Set the heat press or oven to the right time and temp. Most items are pressed between 185 to 205°C for 45 to 90 seconds. Pressure is light to medium. During the press, sublimation ink turns to gas, moves into the coating, and cools back to a solid. Remove paper while warm. Let the part cool before packing.

What Packaging Products Can Be Customized With Sublimation Printing?

Sublimation printing is ideal for various types of packaging products, including coated soft goods and hard goods. Think gift bags, drawstring pouches, coated box sleeves, tins, and jars. If the surface has a polyester or a polymer layer, the sublimation printing process can bond the color inside it.

Reusable Bags

Poly or poly-cotton bags with a high poly content can take sublimation prints very well. Art looks smooth and bold. Great for gift sets, trade samples, or event packs. Confirm fiber content is 65% or higher for the best bond.

Drawstring Pouches

Poly micro or satin pouches show clean edges on intricate designs. They add value to small goods like cosmetics, perfumes, watches, and tech items. Add a hang tag for specs and use heat-resistant packaging tape to place art with care.

Poly-Canvas Bags

Thick poly canvas gives a premium feel and holds high-resolution designs well. Use a pressing pillow to keep seams from causing uneven pressure. Pre-press to clear moisture before the main press.

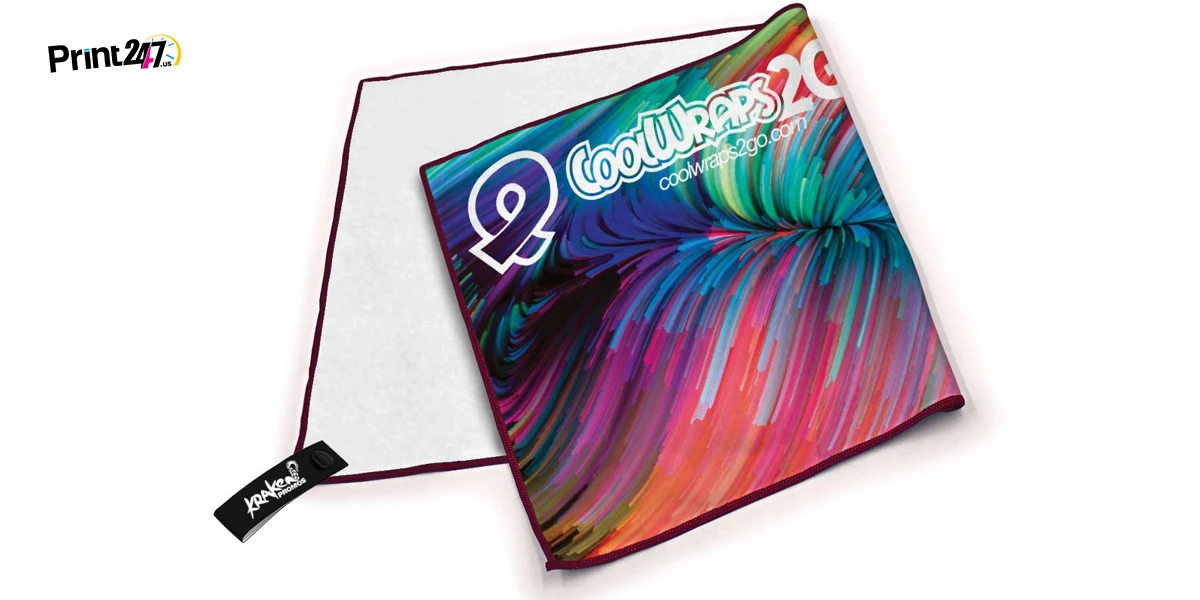

Microfiber Cloths

These are classic sublimation blanks. They take fine text and small logos. Include them in kits as a simple add-on with great color hold. Pack flat between sheets to prevent curl after press.

Coated Cardboard Boxes

Standard paperboard will not work, but polymer-coated box sleeves or insert panels do. You can sublimate the panel, then mount it to the box. This is a smart path for short runs or special drops.

Polymer-Coated Metal Tins

It’s great for tea, candy, or gift sets. The coated lid or face plate takes a full-color transfer with crisp lines. Keep dwell time steady to avoid warping. Let the metal cool before handling.

Polymer Plastic Boxes

Some clear or white plastic boxes with a polymer layer can accept sublimation transfer decals or panels. Apply the printed panel on the flat area, not across deep ridges.

Pros and Cons Of Sublimation Printing

Sublimation can be a smart fit for branded packaging parts, short runs, and gift sets. It is fast to set up, gives smooth color, and handles fine detail. There are limits to it. Size limitations are tied to your press and require a polyester or polymer coat.

The following are some pros and cons associated with this printing type.

Pros of Sublimation Printing

- Smooth, no hand feel on the print area

- Photo-like color for custom designs

- Handles complex designs and small text well

- Fast setup for prototypes and small lots

- Lower waste compared to some analog methods

- No weeding or screens to make

- Strong wear and rub resistance on coated items

- Easy to repeat once settings are dialed in

- Works with many sublimation blanks

- Good full-color transfer without extra layers

- Clean edges with special transfer paper

- Fits on-site sample runs for sales teams

Cons of Sublimation Printing

- Surfaces must be polymer-coated or have polyester fabric

- Not suited for cotton or raw paperboard

- Press size limits oversized panels

- Curved or deep shapes may need special wraps

- Color on dark items needs a white base coat panel

- Some items need tight temp control to avoid warp

- Entry setup still needs training and a safe space

Why Choose Sublimation Printing?

Pick sublimation printing when you need bright color, small lots, and sharp detail on coated goods. Print essentially rests on the surface, so there is no need to clean it, and it resists wear. It is a smart add-on to a box line that needs photo panels, promo kits, and quick-turn samples.

Vibrant, Detailed Designs

You get rich color and crisp edges on high-resolution designs. Dye sublimation handles fine fades and tiny text better than many transfer methods. For hero panels or promo sleeves, this helps your brand look sharp in photos and on the shelf.

Long-Lasting Prints

The ink bonds inside the coat during the heat transfer step, not on top. Thus, it is resistant to rubbing and scratching. Also, cracks are less likely to occur. For packs that ship and move a lot, this adds real value.

Versatile Applications

From polyester fabric totes to coated tins, the list of sublimation blanks is wide. You can run one-off sales samples or a few hundred units. Swap files, reprint fast, and keep color close by using a press log.

Eco-Friendly Process

No screens, no washout, and low waste for small runs. You print only what you need on transfer paper and press. Many shops use water-based Sublimation Ink. Always follow local rules on disposal and ventilation.

Sublimation Printing Vs Other Printing Methods

Sublimation is great for color depth and detail on coated items. Heat transfer vinyl, screen print, and DTG each have their own sweet spot. Use the tables below to pick what fits your run size, substrate, and finish goals.

Sublimation vs. Heat Transfer Printing

Sublimation vs. Screen Printing

Sublimation vs. Direct-To-Garment (DTG)

Final Thoughts

It is worth your time to explore sublimation printing if you want color-rich panels, quick samples, or short runs on coated packaging. It gives smooth prints, sharp detail, and strong wear on polyester fabric and polymer-coated goods. Ideally, you'd like a partner who will simplify the process from beginning to finish. Contact Print247, one of the leading local packaging suppliers in the US, for more information. Our packaging services include free design support, eco-friendly materials, fast shipping, and physical samples for leading brands in the US. Let's set your line up and get your next launch off to a great start.

FAQs

Can Any Printer Do Sublimation?

No. To print dye sublimation ink, you need a sublimation printer or an inkjet printer that can be converted to print dye sublimation ink. Regular inkjet printer models with normal dye or pigment ink will not turn to gas at press temps. Use gear that is made for dye sublimation and test before production.

Is Sublimation Printing Better Than Vinyl?

For coated goods and polyester fabric, yes. Sublimation printing gives smooth in-surface color and handles small text well. In addition to being positioned on top, heat transfer vinyl can crack. For cotton tees or dark items, vinyl may still be the better pick.

Does Sublimation Printing Use White Ink?

No. White ink cannot be used in sublimation printing. On dark or clear items, use a white polymer-coated panel or a white base insert. For tees that need white ink, DTG or screen print is a better match.

What Is The Meaning Of Sublimation Printing?

It is a printing technique where sublimation ink turns to a gaseous state under heat and pressure. The gas bonds to polyester fabric or a polymer coat, then cools to a solid inside the surface. In this case, the color is a part of the item.

How Does A Sublimation Printer Differ From A Regular Printer?

A regular inkjet printer uses dye or pigment that sits on paper. A dye sublimation printer uses dyes that can turn into gas under heat. It also uses sublimation paper that releases ink cleanly during press for a strong heat transfer.

How Can I Get The Cheapest Sublimation?

Start with an inkjet printer conversion, entry-level sublimation paper, and a small flat heat press. Buy a few blanks for testing. Keep the setup simple. As volumes grow, upgrade to a dedicated dye sublimation printer for better speed and color control.

Is Sublimation Ink Permanent?

On the right surface, yes. Sublimation Ink bonds inside the coating and resists rub and peel. On the wrong surface, like cotton or uncoated paperboard, it will not bond and will fade. Match the substrate to the method.

What Type Of Image Is Best For Sublimation?

Use high-resolution designs at 300 DPI at the size. Vector logos stay sharp. For photos, use clean lighting and sRGB color space. Avoid heavy filters that may shift during the press process. Always soft proof on your media if time allows.

.jpg)

.jpg)

.jpg)