Biodegradable Cardboard Transforming Cosmetic Packaging: The Future of Sustainable Boxes

.jpg)

If you sell beauty products, you know the box is the first touch. It has to look great, feel premium, protect the bottle, and still be kind to the planet. That is a big list for a small carton. Biodegradable cardboard helps you meet it. It is strong, printable, and made from renewable fiber. It also has a clear end of life when you design it right.

In this informative blog, we are going to keep things simple and hands-on. You will learn what “biodegradable†means in the context of cosmetic packaging. Moreover, you’ll learn how it differs from “compostable,†which boards to choose, and which inks and coatings work best.

We will walk through design do’s and don’ts, honest claims, rules to watch, and a step-by-step plan to launch. Think of this as a friendly playbook for packaging, sourcing, and brand teams who need a better box without long meetings or uncertainty.

Paper and paperboard recycling in the U.S. has held above 68% in EPA’s last full reporting cycle, making fiber a strong end-of-life path compared with many other materials. (Source: US EPA)

What does “biodegradable cardboard†really mean?

Biodegradable cardboard is paperboard that breaks down by natural microbes into water, carbon dioxide, and biomass over time. Plain fiber does this well. The confusion starts when a carton adds films, foils, thick varnishes, or plastic windows. Those layers can slow breakdown or block it. “Compostable†is different.

Compostable packaging must pass strict lab tests that check disintegration speed and safe residue under set heat and moisture. In the U.S., the key test is ASTM D6400. If you plan to say “compostable,†you need proof that matches one of these standards.

Biodegradable vs Compostable VS Recyclable

Why beauty brands are moving to biodegradable cardboard boxes?

In the modern era, customers want less plastic and less waste. Retailers want clear, honest claims. Designers want strong color and clean folds. Cardboard cosmetic boxes check these boxes. It prints well, feels natural, and supports many premium looks.

The key is to keep the structure simple so mills can recycle it at scale. The U.S. has been leading the world in material recovery for years. Paper and paperboards accounted for just over 68% of the total amount reclaimed during the last full recycling cycle. (Source: US EPA)

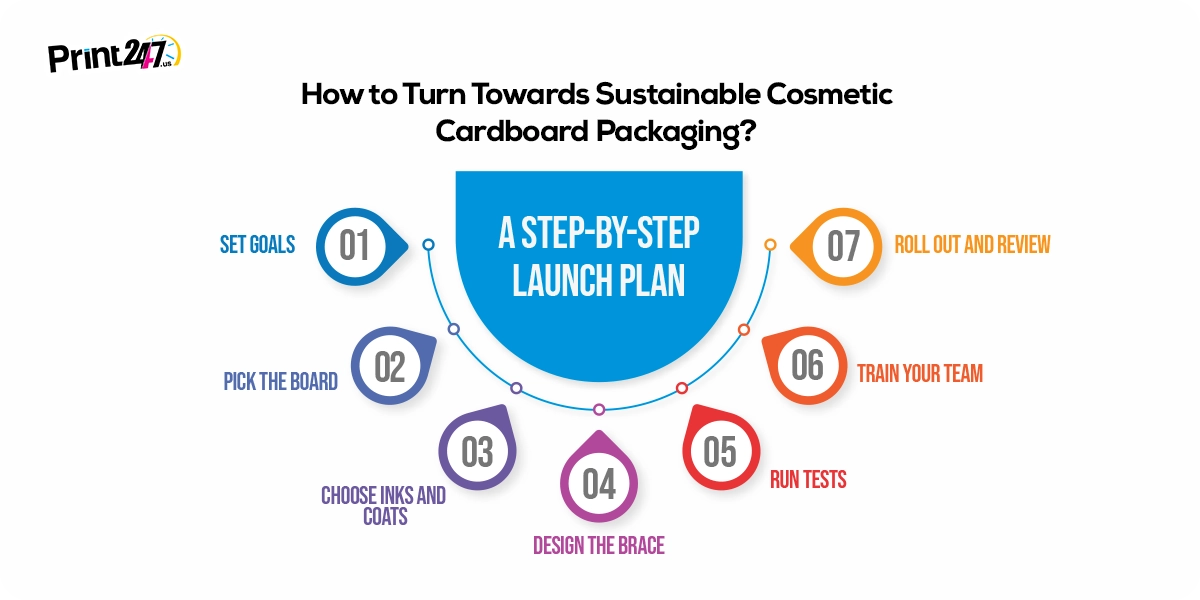

How to Turn Towards Sustainable Cosmetic Cardboard Packaging? A Step-By-Step Launch Plan

Biodegradable cardboard packaging helps beauty brands create standout packaging solutions that enhance customer experience. It also raises the shelf appeal of their beauty products. This packaging can be environment-friendly in a number of ways, from accepting biodegradable options to engaging in responsible sourcing.

Here’s how you can turn toward biodegradable cosmetic packaging made with cardboard.

#1 - Set goals

Write three targets on one page: FSC or recycled content, “recyclable first†claim, and a limit on non-fiber extras. Add a simple line for your team: “No magnets. No full-panel films.â€

#2 - Pick the board

Choose SBS for bright whites, FBB for stiffness, or CRB for high recycled content. Match the caliper to the heaviest SKU. Do a quick shelf-life check for rub and humidity.

#3 - Choose inks and coats

Go water-based for inks and topcoats. If you need soft-touch, request a water-based option listed as “repulpable†by your supplier. IFC guidance favors water-based systems to lower solvent exposure in print plants

#4 - Design the brace

Replace plastic trays with a paper insert. Use a cross-brace, sleeve, or rolled U-channel. Keep glue lines thin

#5 - Run tests

Do a carton crush test and a rub test. Ask a mill or lab for a small repulp test, or use your converter’s data sheet that shows fiber yield.

#6 - Train your team

Give designers a one-page finish guide. Give buyers a vendor checklist. File all proofs and certificates in one shared folder.

#7 - Roll out and review

Print a small run first. Collect returns and feedback from your warehouse and stores. Tweak the caliper or brace only where needed.

How to pick the right cardboard for your cosmetic packaging?

The cosmetics enterprise is becoming increasingly biodegradable due to consumers' increasing awareness of sustainability. Packaging materials can affect the environment and the attractiveness of a product positively. It is key to reduce hazardous packaging waste and increase the effectiveness of a product.

Use this as a quick map:

SBS (solid bleached sulfate): Bright white, smooth, great for high-end print.

FBB (folding box board): Layered structure, stiff at a lower weight.

CRB (coated recycled board): High recycled content, good choice for eco goals.

Caliper or GSM: Match the weight to the product. Heavier glass needs a thicker board.

Certification: Ask for FSC to show responsible forestry.

We have made you aware of popular cardboard materials for cosmetic packaging. Now think about whether they align with your brand's sustainability goals. Your next environment-friendly cosmetic product can benefit from these materials. t.

How to size the box for strength and feel?

To size the sustainable cardboard box for your product, you need to follow some basic steps. Measuring accurately product’s dimensions and adding space for cushioning is highly essential.

Think in layers. The box panel needs stiffness. The crease needs a clean fold without cracking. Inside, a simple paper insert can lock the bottle and replace the foam.

To measure accurately, try this order:

Set a target drop and compression test based on your carrier.

Choose a caliper for the worst-case SKU (usually the heaviest bottle).

Align the grain with the most stressed panel to reduce the bulge.

Add a paper brace only where the bottle rattles.

Turning grain to match the main panel often reduces edge cracking during folding.

Print surface that stays sharp

Gloss or silk coatings help color pop. If you want a soft feel, ask for a water-based soft-touch that has been tested for repulping. Keep heavy plastic laminates off the full panel. Small spot effects are fine. The aim is a premium look without blocking fiber recovery.

How to design green beauty packaging for recycling first?

It is never too early to start thinking about your packaging design. You should pay as much attention to it as you would to the formulation of your beauty products. Beauty brands are doing their best to minimize their impact on the environment. A “recyclable first†box is both brand-safe and mill-friendly. The material should be mono-fiber, excesses should be kept to a minimum, and the box should be easy to flatten.

Follow these simple tips.

Skip big windows. If you need one, keep it small and thin.

Avoid magnets and thick glitter. They lower the fiber yield or trigger rejects.

Choose glue zones wisely. Thin adhesive lines help pulping.

Switching to recyclable cosmetic packaging benefits the environment and appeals to eco-conscious consumers. Using this tactic can help brands lessen their ecological footprints and contribute to a more sustainable future.

Make your cardboard cosmetic packaging look premium without hurting recycling

An exclusive, high-quality, and innovative luxury product is perceived as high-end. Having a higher brand value makes consumers feel more confident about a brand.

As a cosmetic product manufacturer, you can still have a luxury feel on your zero-waste cosmetic packaging without affecting recycling efforts. Try texture, emboss, or a small foil accent. Use strong color blocks with clean type. Give a brief description of the product: what it does, how to use it, and how to recycle the box.

Here are some tips.

A small foil band around the logo

Soft-touch on the main panel only

Blind emboss on the brand mark

A tiny QR code to your care page

Adding hot-foil accents to smaller areas is less of an issue for mills than full-panel laminations.

Final Thoughts

Start with a fiber-only mindset. Pick an FSC or recycled board that fits your heaviest SKU. Keep finishes simple and water-based. Add small touches, not full-panel films. Replace plastic trays with a folded paper brace so the product does not rattle in transit. Put clear words on a tuck flap so customers know to flatten and recycle.

If someone asks for compostable, be honest about access and the need for real testing. Recycling is the strongest path for most beauty boxes right now, and your design can support that path with ease.

Above all, test early with your converter and with a mill or lab. That way, your sustainable beauty box will not only look premium on day one, it will also pass the end-of-life check that matters to your customers and your retail partners. A simple fiber box, designed well, is a smart step forward.

FAQs

What is the difference between biodegradable and compostable cardboard?

No. A biodegradable material decomposes over time. Compostable means it passes lab tests under controlled conditions. For packaging, that is ASTM D6400 in the U.S. or EN 13432 in the EU. If you plan to claim compostability, ask for a certificate.

Can I still use foil and call the box recyclable?

Yes, if the foil area is small and the rest of the box is fiber. Avoid full-panel films. Ask your converter for data that shows mill-friendly performance.

Do water-based inks really hold up?

Modern water-based and soy inks print with strong color and can reduce VOC exposure in plants. Always run a press proof for your exact board and coat.

Which type of cardboard is best for premium whites?

SBS gives very bright whites and smooth print. If you want more recycled content, test CRB with a white top coat. Ask for FSC as a base request.

.jpg)

.jpg)

.jpg)