Standard Shoe Box Dimensions: How To Measure And Choose The Right Size

.jpg)

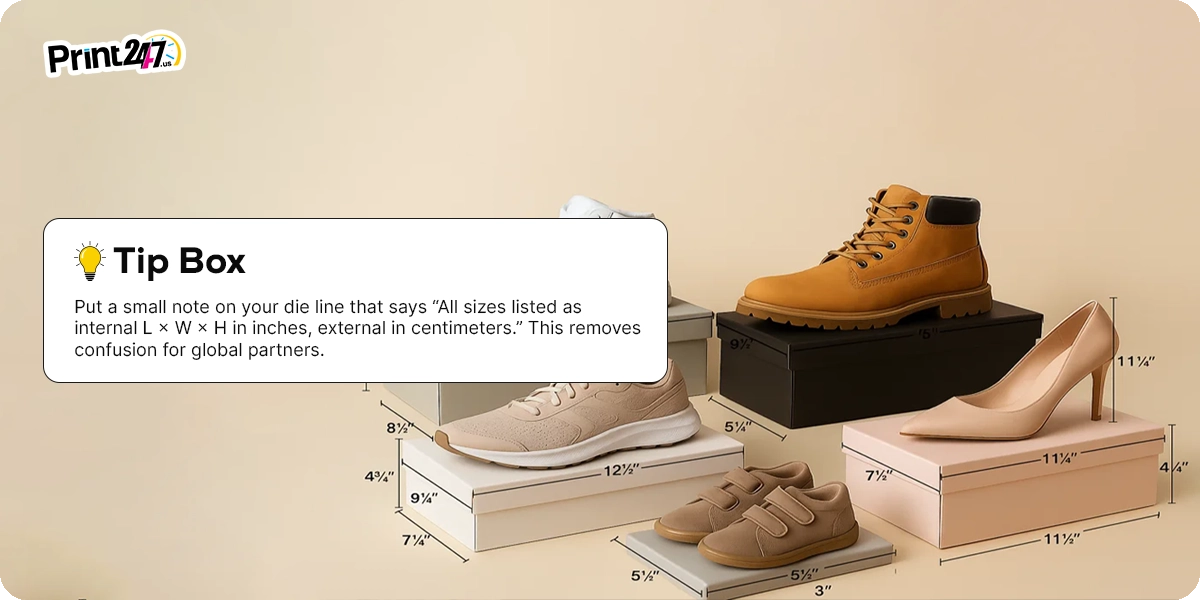

The standard retail shoe box dimensions fall near 13 × 8 × 5 inches for men, 12 × 7 × 4.5 inches for women, and 10 × 6 × 4 inches for youth. Measure length, width, and height on the inside first, then repeat outside for shipping and note box weight.

Are you going to start a shoe brand? Knowing the actual measurement of your shoe box is highly essential for the presentation and marketing. Sizing a shoe box looks simple, yet it affects product safety, shipping cost, and your brand story. Renowned footwear brands like Nike, Adidas, and ASOS are working on key strategies to improve their packaging solutions and customer experience. If you buy or specify packaging for a footwear brand, you need a clear way to plan shoe box dimensions that fit pairs without waste.

In this detailed blog guide, you will learn how to measure boxes step by step, what “L × W × H” really means, where tolerances show up, and how retail sizes differ from shipper sizes. We will also share common ranges for men’s, women’s, and kids’ footwear so your team can order with confidence and keep returns down.

Let’s get started.

Currently valued at USD 3.55 billion, the shoe packaging market is expected to grow at 3.51% CAGR to USD 4.22 billion by 2030. Source: MordorIntellegence

Key Takeaways:

- Men's average is 13 x 8 x 5 inches; women's is 12 x 7 x 4.5 inches (internal).

- External size is used for shipping costs; internal size is for product fit.

- The standard manufacturing variance is small: 2 - 3 mm (tolerance).

- Shipping cartons are 1.5 to 2 inches larger than the inner retail box, increasing DIM weight.

- Specialty footwear like boots needs up to 9 inches of height for protection.

- Sandals and loafers can use low boxes, often just 3 - 4 inches high, to save volume.

- Box weight is minimal (under 1 lb), but its volume determines the high shipping cost.

Why Do Shoe Box Dimensions Matter?

Shoe box dimensions play an important role in helping a brand save money, protect its products, and offer engaging presentations at retails shelves and social media. It also speeds warehouse work and keeps carriers happy. Right-sizing footwear packaging helps you cut damage claims, keep brand lovers smiling at unboxing, and avoid chargebacks tied to wrong labels or oversize packs.

Here’s the further explanation of why shoe box measurements matter.

1) Product Protection & Returns

Shoes must not move during shipping or transport. The right fit packaging solution, plus a simple insert, prevents scuffs, wrinkles, and heel dings. With fewer damages and fewer returns, there will be fewer reverse logistics or returns. Your CS team spends less time on claims and your margins look better.

2) Brand Presentation & Unboxing

It is the size of the box that shapes the first impression. Tight but not cramped looks premium. Consistent shoe box size helps printers keep colors even and logos centered. A neat open, with tissue and card, sets a clean stage for photos and social posts. Known footwear brands like Christian Louboutin, Jimmy Choo, or Gucci treat the unboxing process as a luxurious, multi-sensory ritual.

Storage & Retail Efficiency

Shoe boxes' sizes are more than just a way to protect and present products; they're also strategic decisions that directly impact storage and retail efficiency. Right-sized cartons stack more safely. Stores can face more pairs per shelf. A clean, repeatable method of measuring shoeboxes reduces scanning time and speeds up restocking.

Shipping Cost & Sustainability

Smaller outside size cuts DIM (Dimensional) weight. It’s the pricing model that renowned global carriers like FedEx, UPS, and DHL use. It can lower parcel costs and Carbon emission. Less board and right-fit fillers reduce waste, which helps your ESG reports.

Key Terms Used To Calculate Shoe Box Dimensions

Understanding the packaging language is highly essential before you choose the right box for your shoe brand and calculate dimensions. It is common for teams to speak past each other when it comes to size. There is a misconception about the size of net boards among printers. The operations team wants inside space. Carriers are rated by the outside. Use one format across teams, and your numbers stay clean.

Internal vs External Measurements (when To Use Each)

Use internal measurements to confirm product fit and insert space. Use external measurements for pallet plans, shelf schematics, and carrier rules. It goes on both the specification sheet and the die line. It is important to distinguish between the two so there is no confusion.

Orientation: L × W × H (Lid on Top)

State the length of the box as the longest side, width as the shorter side across the lid, and height from base to lid underside. Write it as L × W × H. Keep the same order in every doc, PO, and drawing. When you have these details, you can also find the usable space or volume of a shoe box. Use the following formula for that.

Volume = Length x Width x Height |

Tolerance & Variances (+/− 2 - 3 mm Typical)

While custom box manufacturers strive for perfect shoe box sizes, mass production may result in misalignments. Paperboard and corrugated can shift a little at the fold and glue. Expect about 2 to 3 mm variance. If you run snug inserts or tight shelves, plan a buffer or raise board grade.

For example, if a footwear box is specified to be 300 mm long, an accepted box could be anywhere between 297 mm and 303 mm.

Units: Inches vs. Centimeters

Retail in the U.S. often uses inches. Many packaging manufacturing factories and global teams work in centimeters. Include both to avoid errors. Example: 13 × 8 × 5 inches equals about 33 × 20 × 13 cm.

How To Measure A Shoe Box's Dimensions? (Step By Step)

Good shoe box measurements start with the product pair you plan to pack. Organize the shoes as they ship, include tissue, and check for heel counters or tall tongues. Take internal sizes first. Then close the lid and record outer sizes and the gross weight for freight.

Always remember that external dimensions are measured for shipping costs and internal dimensions are measured to ensure the product fits inside the shoe box.

Tools You’ll Need:

- Rigid ruler or quality tape measure

- Caliper for tight fits or inserts

- Scale that reads in ounces and grams

- Notepad or spec sheet template

- The actual shoe pair with tissue or wrap

Step 1: Measure The Length (Longest Internal Side)

Open the empty box. Measure the longest inside wall from corner to corner. Keep the tape flat. Add a small buffer if the toe box is wide or the heel counter is stiff. Note the value as internal length.

Step 2: Measure The Width (Shorter Internal Side)

You need to measure the width across the opening of the lid from inside to outside. Check the widest point of the pair when placed as intended. Wide sneakers or side-by-side sandals may need extra width for easy pack-out.

Step 3: Measure The Height (Bottom Interior To Lid Underside)

Now measure the inside height from the base to the underside of the closed lid. Include any paper, divider, or insert. Tall tongues and stacked heels can rub the lid if the height is tight.

The lid should be closed, the corners squared, and the dimensions of the box measured from outside: L, W, and H. Weigh the packed box. Write both sets on your spec sheet.

Average External Box Dimensions For Famous Footwear Brands

What Are Standard & Average Shoe Box Dimensions?

Here is a quick table of common shoe box dimension ranges used by U.S. brands. These are working ranges, not hard rules. Style, inserts, and brand look will shift the final pick.

Men’s shoe box dimensions

Most men’s lifestyle pairs sit near 13 × 8 × 5 inches inside. Size 12 and above may need up to 13.5 - 14 inches of length or a half inch more height for chunky midsoles. For boots, consider taller boxes with a heel cup insert to lock the pair.

Women’s Shoe Box Dimensions

Women’s casual pairs fit around 12 × 7 × 4.5 inches inside. Heels, wedges, and platforms may need up to 5 to 5.5 inches of height or a divider so straps and buckles do not mark the upper.

Children’s Shoe Box Dimensions (Average)

Children's shoe packaging is unique because it caters to a massive size range, from newborns to older children. Therefore, there is no standard kids' box dimension.

- Newborns (0 - 2 years): about 6.25 × 4.25 × 2.75 inches inside.

- Toddlers (2 - 4 years): about 8.25 × 5.25 × 3.25 inches inside.

- Older Children (4 - 12 years): about 10.25 × 6.25 × 4.0 inches inside.

Unlike adults, parents often purchase children's slightly large shoes that accommodate growth. However, brands can’t make the kids' show box excessively large. Packaging must keep the shoe secure and prevent it from sliding or being damaged.

Specialty Footwear: Sneakers, Boots, Sandals And Loafers

Standard box dimensions work well for typical shoes. However, specialty footwear requires custom packaging due to its unique shape. These shoes need more height for padded collars. Boots need either length for laying on the side or height if standing upright. Sandals and loafers can use lower lids to save DIM weight and shelf space.

What’s the Difference In Retail vs. Shipping Shoe Box Sizes?

Retail shoe box is the product packaging and is built for branding, shelf fit, and neat stacks. Shipping shoe boxes focuses on protection, edge strength, and courier rules. There are many brands that place their retail boxes inside mailers. There are some companies that ship SIOC (Ships In Own Container), which means the retail box is the outer box.

Here’s a table comparing the retail and shipping shoe box dimensions is an excellent way.

A shipping shoe box size is typically 20% larger than the actual shoe. This extra area accommodates protective padding. The boxes are constructed from corrugated cardboard to give them a more durable build.

How Much Does A Shoe Box Weigh?

The weight of a standard shoe box is between 0.4 to 0.5 pounds (approximately 200 to 250 grams). Shoe box weight typically depends on material thickness and size. If we further go into details, the women's shoe box weighs approx 115 to 170 grams, mens shoe box weighs approx 170 to 225 grams and kids shoe box weighs about 100 to 150 grams.

The weight of a shipment has an effect on freight and handling. You should record the weight of the empty box and the weight of the packed box. A heavier board and glossy coat may look nice, but they can increase costs when scaled across thousands of units.

How Does shoe Box Weight Interact With DIM?

In the case of a DIM weight that is greater than a scale weight, lighter materials will not change the bill unless you also reduce the outside size. It is important to balance the cube and the structure.

Final Thoughts

Knowing the standard shoe box dimensions is not guesswork. It is a simple repeatable process that blends product fit, shelf plans, and freight math. Pick your inside size for the pair and insert. Note your outside shoe box size for pallets and carriers. Record weights for both empty and packed. Then keep those specs clean across seasons so printers, DCs, and stores do not miss.

If you want help, order from Print247. We supply U.S. brands with custom footwear boxes and mailers that look great and work hard. Our services include free design assistance, eco-friendly materials, fast shipping, and the ability to see samples in person. There are fewer headaches on launch week when your teams get boxes that fit, budgets that match, and budgets that hold.

FAQs

How do I measure a shoe box for shipping?

Measure outside length, width, and height with the lid closed, then weigh the packed box. Record both the external sizes and the gross weight. Keep internal sizes for fit notes and inserts. Carriers bill by the higher of scale weight or DIM weight.

Are there different-sized shoe boxes for different types of shoes?

Yes. Casual sneakers often need extra height for padded collars. In some cases, heels need more height to fit the heel seat. For boots, a taller or longer box may be needed, sometimes with a heel cup insert. For sandals and loafers, lower lids can save space.

What is the size of a Nike shoe box in cm?

There is a wide range of sizes for men of different models and years, but a typical size for men is 30.5 cm L x 20.5 cm W x 12.5 cm H inside. Women’s shoe boxes can sit near 30 × 18 × 11.5 cm. Always confirm current specs with your vendor sheet and sample before mass print.

Does the shoe box size change for international shipping?

The retail shoe box usually stays the same. The shipper often changes. Long routes and tough hubs may need thicker board, stronger corners, and a little more clearance for pads or airbags. External size and weight control rates and customs checks.

What are the dimensions of a standard shoe box?

For many men’s pairs, about 13 × 8 × 5 inches inside. For women, about 12 × 7 × 4.5 inches. For youth, near 10 × 6 × 4 inches. These are working ranges. Check your style, inserts, and retailer shelf limits before finalizing.

How big should a box be for bulky sneakers?

Plan for extra height and width. Many bulky sneakers fit best near 13.5–14 × 8.5–9 × 5.5–6 inches inside. Test with your thickest collar and largest outsole in the line. Use a shaped insert to stop heel rub.

Can one shipping shoe box size work for most orders?

Two or three sizes cover most pairs. Many brands use 14 × 9 × 6, 13 × 8 × 5, and 15 × 10 × 6 inches. These sizes stack well and hit common carrier tiers. Add a larger size for boots or multi-pair orders.

.jpg)

.jpg)

.jpg)