Coffee Sticker Placement Guide: Where to Stick for Maximum Brand Recall?

.jpg)

Put stickers where buyers and staff will see them first: the front center of bags, the front face of cups or sleeves, and the front lid of tins. Create coffee packaging stickers that are sized to the flat panel, with clear coffee label designs and the right adhesive. With this, you will achieve greater visibility, faster reorder decisions, and stronger brand recall.

Small stickers or labels make a big difference for coffee brands that sell to cafes, stores, or wholesale buyers. A clear product label is the right thing that helps a purchasing manager, barista, or stock clerk read roast date, batch number, and brand quickly. Moreover, it reduces confusion, speeds reorder cycles, and lowers mistakes during packing for e-commerce teams.

We have written this guide to give step-by-step coffee sticker placement rules for the most common formats. We have discussed materials, tools, staff training, and real tests that you can run in your own plant. Here you'll find simple, practical tips for applying stickers to coffee packaging, as well as advice on coffee label design so your packs look professional and clean.

Let’s start.

Key Takeaways:

- Front center placement ensures maximum buyer and staff visibility.

- Stickers offer cost-effective, quick branding and vital product data.

- Consistent sticker placement builds customers' quick visual brand memory.

- Placement must suit the package format, material, and surface texture.

- Prepare surfaces and use templates for perfect, consistent alignment.

- Smooth stickers center to edge with a roller for full adhesion.

- Avoid placing stickers over package seams or fold lines.

- Test adhesion and placement under actual shipping conditions beforehand.

- A simple staff training routine ensures professional and clean results.

Understanding the Role of Stickers in Coffee Branding

Stickers do more than show a logo. They are a cost-effective tool and play a vital role in quick coffee branding. They contain vital data, create consistent brand moments, and let you make fast changes without reprinting your primary pack. A sticker can display the roast date, a batch number, a cafe code, or a special promo. It allows workers to confirm freshness, rotate stock, and reorder correctly.

Stickers also help in building customers’ visual memory. When the same logo, color, and placement repeat across mylar pouches, boxes, and sample packs, people learn to spot your brand. That visual habit matters in busy back-of-house areas where buyers make quick choices.

Coffee labels give you an easy way to provide product-specific information. If a cafe orders a custom blend, you can add a label with the cafe name and handling notes. That cuts the need for unique packaging and keeps costs lower.

When it comes to processes, stickers are a control point. You can mark priority orders, tag QA-inspected orders, or label samples for trade shows. They let you run short promotions or highlight seasonal blends without building new artwork files for marketing. If you include stickers in your operational playbook, you will see fewer mis-picks and faster reorder cycles.

What Are Coffee Packaging Formats Before Sticker Placement?

Every coffee package gives you a different space to place a sticker. The type of pack, the finish, and the seams all change what spot is best. Look at your package and note the largest flat panel, the zipper or seal, and how it will be handled in a cafe or on a shelf.

Material choice also matters in the most effective coffee sticker placement. A glossy pouch behaves differently from a kraft bag. Curved pouches can lift sticker corners. Metal cans offer a smooth surface but can get oily from handling. Choosing the appropriate sticker adhesion tips is the key to preventing early peeling and tears. Make a simple checklist before a production run: surface type, touch points, display direction, and finish. Select label stocks, adhesives, and placement based on that.

Most Common Coffee Packaging Types

A coffee package maintains its freshness and protects it from environmental hazards that could spoil its taste. There are a few packages that most coffee brands use. Each format has a best practice for sticker placement and a few simple pitfalls to avoid.

Here are some common types of coffee packaging.

Stand-up pouches

Stand-up pouches offer a broad flat front above the zipper. It is best to place the zipper above the center of the front. The spot faces forward on shelves, making it easy for bartenders and buyers to read. Place coffee stickers away from zipper folds or areas where the bag will be compressed. When using glossy pouches, make sure the label stocks are synthetic to prevent lifting. For matte pouches, a paper label with a higher tack often works better.

Flat-bottom bags

Flat-bottom bags stand rigidly and create a rectangular front panel. Place the brand sticker around the top center of the flat bottom pouch where the eye lands on a shelf. The flat geometry allows larger labels and easier barcode placement below the brand sticker. If you include roast notes, place them beneath the logo to keep the brand visible.

Quad seal bag

Quad seal coffee bags have four distinct flat panels and strong vertical edges. Limit sticker size and place on the primary front panel. You should avoid putting stress on the adhesive by avoiding edges and folds. It is best to use the side panel that stays flat for functional stickers, such as lot codes.

Pillow bag

In coffee packaging, pillow bags curve at the sides and often have a prominent bulge in the middle. Attach stickers to the upper third of the front panel where the bag appears flat when packed. It is best to stay away from curves near the bottom, especially those near the belly.

Metal cans

Metal coffee cans give a smooth, rigid surface. Apply the main label to the body aligned with the front. A small date or batch sticker should be added to the lid. Clean the metal first to remove oils and fingerprints. If your label wraps around, make sure the logo is aligned perfectly.

Kraft paper bags

Kraft paper has a natural look with texture. The texture of surfaces reduces the contact area between adhesives and makes them work harder. If you need stronger adhesives, use uncoated paper labels or pressure-sensitive stocks designed specifically for kraft paper. Place the coffee sticker in the center front and press firmly with a roller.

How to Place Coffee Stickers Perfectly on Bags and Packaging?

Preparation is key to success in coffee sticker placement. Good placement is a repeatable process. Without it, even high-quality labels can look sloppy. Test one or two methods before settling on one that your team uses all the time. Packs should look like brands, not like workshops, so you need to be consistent.

Materials and Tools for Professional Coffee Sticker Application

Keep tools simple. The right tools let a small team apply labels neatly and fast.

You will need:

- Cleaning wipes for glossy surfaces

- A label dispenser or tabletop applicator

- A small roller to smooth labels

- Cardboard jigs to set the exact spot

Use both permanent and removable adhesives depending on the purpose. Vinyl or poly labels work for high moisture areas. Paper labels suit Kraft and matte packs.

Step-by-step guide to placing coffee stickers

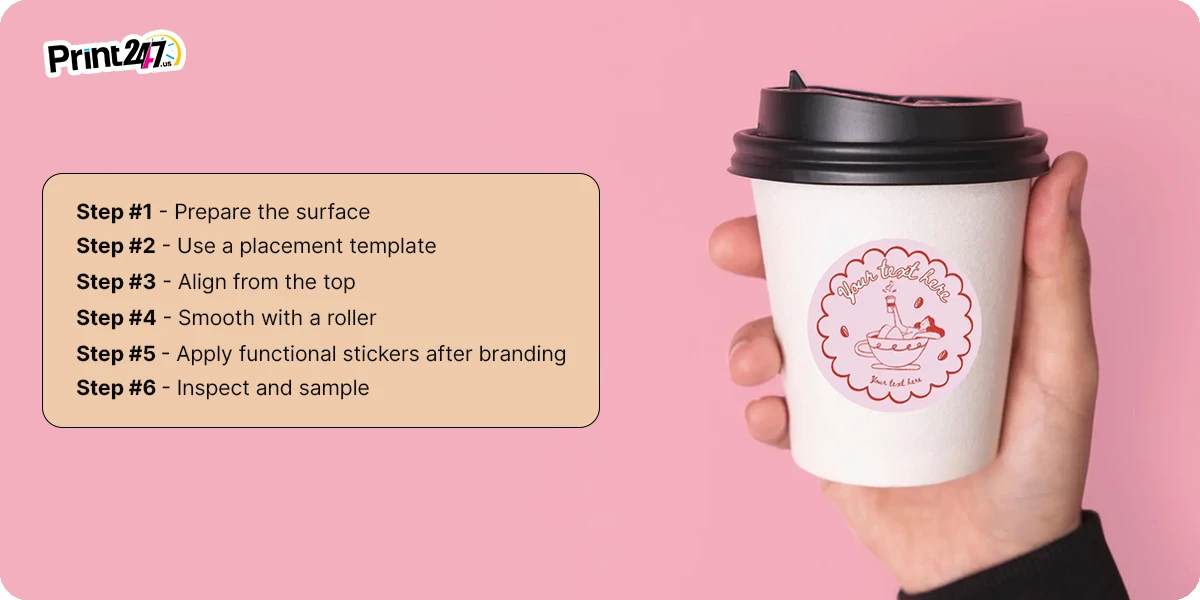

Follow this step-by-step process for placing the stickers perfectly on coffee packaging.

Step #1 - Prepare the surface

Surface preparation is the first step. To do it perfectly, use an alcohol pad to clean shiny surfaces that have dust or oil spots. If you are using kraft or uncoated paper, use a brush to remove dust. When the surface is clean, the adhesive will set more quickly and prevent early lifting.

Step #2 - Use a placement template

A placement template makes the process easy and ensures proper alignment. It is for that reason that a cardboard jig, even hand-cut, is essential in ensuring that every label is positioned in the same place. Slots that fit the pack edge and show the center mark solve most human errors.

Step #3 - Align from the top

When applying, align the top edge of the sticker first and lower the rest. This avoids bubbles and lets you correct orientation before sealing the edge. Aligning the coffee sticker from the top relates to visibility, aesthetic balance, and functional considerations.

Step #4 - Smooth with a roller

The importance of using a roller can’t be overlooked in achieving flawless finishing. Roll the coffee label from the center to the outside to remove trapped air and make the adhesive bite. A small rubber roller is cheap and effective, so you must add it to your tool list.

Step #5 - Apply functional stickers after branding

If you want to add roast date, batch, or barcode stickers, apply them after the main brand sticker so your logo won't be covered. To make it easier to scan and read functional stickers, place them in a standard corner.

Step #6 - Inspect and sample

Inspection is essential to check whether stickers are correctly positioned on coffee packaging or not. The best practice is to inspect one pack every 100 to 200 for alignment and adhesion. Be sure to keep a detailed log of process failures so that you can correct it if you see trends.

Common Mistakes in Coffee Sticker Placement (and How to Avoid Them)

There are simple mistakes that even experienced teams can make that can hurt the brand's image. It is common to apply stickers over seams, to use the wrong adhesive, or not to test stickers under shipping conditions. Each problem has a practical fix and a short test to catch it during packing.

Here are some common coffee sticker placement mistakes and how you can avoid them to prevent financial loss.

Final Thoughts

Stickers are one of the most practical tools for coffee brands. With them, you can update data, mark priority orders, and keep your brand consistent across many different types of packaging. It's best to combine good coffee label design with simple, repeatable placement, the right label stock, and a short staff training routine for the best results.

Test your shipping process and sample runs before moving forward with a full run. Use cardboard jigs for repeatability, roll every label, and inspect random samples. When you buy packaging, ask for physical mockups and try your sticker on a sample pack. In order to avoid costly mistakes and ensure brand recall stickers work effectively, take this step before placing them on the shelf or behind the counter.

If you need reliable coffee packaging, labels, stickers, order now from Print247. We are a custom printing and packaging manufacturer based in Texas. We offer free design assistance, eco-friendly options, fast shipping, and physical samples so your team can test sticker placement before production begins. Your wholesale customers can benefit from sample testing by decreasing returns, increasing reorders, and building a stronger brand.

FAQs

Where should I place stickers on coffee packaging for best visibility?

Place primary brand stickers on the front center panel that faces customers. For bags, place them above the zipper or on the top third. For tins, place the main label on the body and a small date sticker on the lid. For cups, place stickers on the sleeve or the side that faces customers.

Should my brand logo sticker go on the front or top of the coffee bag?

Stick your main logo on the front panel to ensure visibility in retail displays and cafe displays. You should use a small sticker solely to display roast date and batch information so the brand remains clear and readable.

What are the most common mistakes in coffee sticker placement?

Typical errors include placing stickers over seams, using the wrong adhesive for the surface, blocking barcodes, and not testing stickers for shipping. A template and quick sample test prevent most of these issues.

Can sticker placement really improve brand recall?

Yes. When stickers are placed consistently across formats, the eye is trained to recognize your brand more quickly. It is easy to improve recognition with buyers and staff when the placement is clear and repeatable.

How do I test which sticker position performs best for my brand?

For that, you can run a small A/B test by making two sample groups with different sticker placements. Track reorder rates, staff feedback, and adhesion over two to four weeks. Also, run a mock shipping test to check for handling durability.

Does coffee sticker placement differ for bags, cups, and tins?

Yes. Bags favor front-center panels, cups work best on sleeves or the customer-facing side, and tins take body labels plus lid stickers. Pick a placement that matches how the product is handled and where staff look first.

What’s the best material for long-lasting coffee packaging stickers?

Choose synthetic or poly labels for glossy packs and wet environments. For Kraft bags use uncoated paper labels with a stronger adhesive. Vinyl works best for cups and mugs.

.jpg)

.jpg)

.jpg)