CMYK vs. RGB: Why Your Digital Colors Look Different on Print?

.jpg)

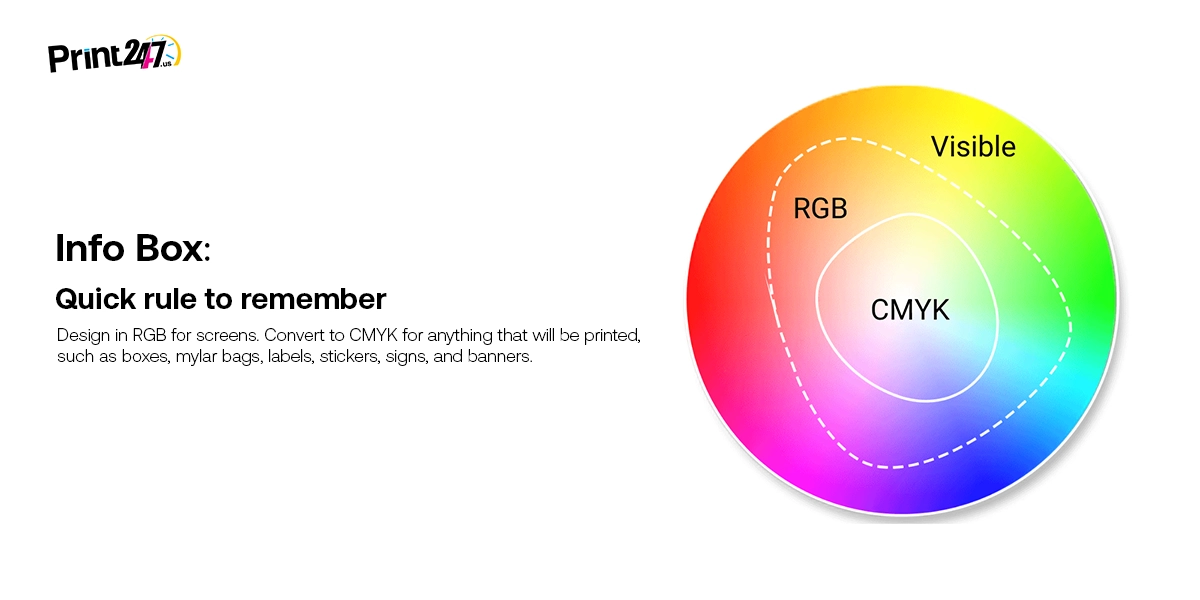

RGB is for screens that make light. CMYK is for printers that use ink. The difference between CMYK and RGB is the main reason for showing dull colors on print. Colors look brighter on screens because light mixes add up, while inks absorb light. For print, convert files to CMYK, use ink-safe colors, and request a proof to keep brand colors close.

Color holds significant importance in our daily lives. You may have noticed one common problem. It is one of the tricky things and can look different on screen and print depending on several factors. Digital color looks bold on your laptop, but your printed box or label may tell a different story. For example, something blue on screen might look purple on print. The reason is simple. The color on screens is displayed with light, while the color on printers is laid down with ink.

Colors can shift when you design in RGB and print in CMYK without any preparation. A bright hue on a website can turn dull on paper. A hot pink on a banner can look flat on corrugate. For brands and packaging teams, that can lead to returns, reprints, and lost time.

Our printing experts have written this guide to give you a brief overview of CMYK vs RGB discussions, how they differ, and how to maintain consistent colors from screen to shelf. The goal is simple. A smoother print run and packaging that fits your brand are just some of the benefits you'll experience.

Key Takeaways

- RGB is a light-based color model for screens

- CMYK is an ink-based color model for print

- RGB often shows brighter greens and blues than CMYK can print

- Always convert design files to CMYK before printing

- Use ICC color profiles from your print vendor

- Bright neon and very deep blue often shift in CMYK

- Gloss, matte, paper color, and texture change the result

- Ask for hard proof when color is critical

- Keep spot colors for exact brand tones when needed

- Calibrate monitors and use soft proofing to reduce surprises

Color Basics: What RGB and CMYK Actually Are?

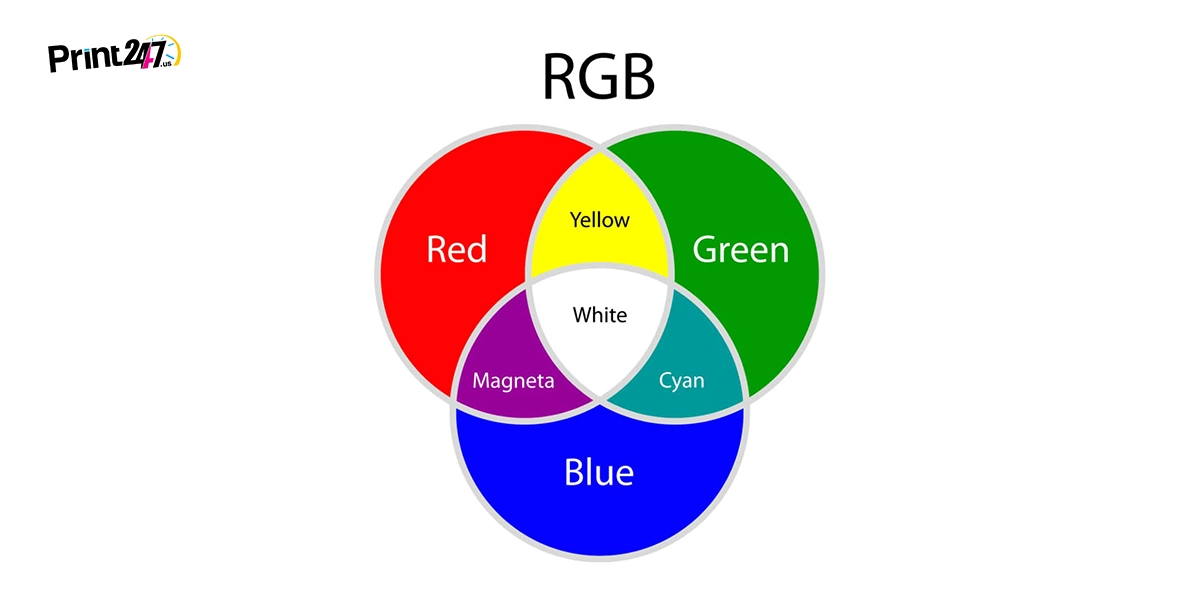

The RGB color scheme combines red, green, and blue light. In digital displays such as computer monitors, mobile phones, and other devices, these three colors are present. A CMYK print uses Cyan, Magenta, Yellow, and black inks. Inks used in printers include these four inks

Here are more details about CMYK vs RGB printing.

What is RGB?

The RGB color scheme stands for Red, Green, and Blue. This model is additive and builds color with light on phones, monitors, and televisions. The intensity of red, green, and blue light varies for each pixel. White is the result of all three being bright. RGB can show very bright colors that ink cannot match.

When to use RGB?

Use RGB for anything that lives on screens. That includes websites, social ads, email images, product mockups for online stores, and digital proofs. RGB previews how color glows on a backlit display. It is not the right final format for print shops, but it helps during design.

What are the best file formats for RGB?

Let's begin with a brief note. When it comes to screens and early stages of design, RGB formats provide rich color and keep detail.

- PNG for web graphics with sharp edges

- JPEG for photos with smaller file sizes

- SVG for logos and icons on the web

- PSD or AI for layered working files in RGB

- PDF/X with RGB placed art only for review, not for final print

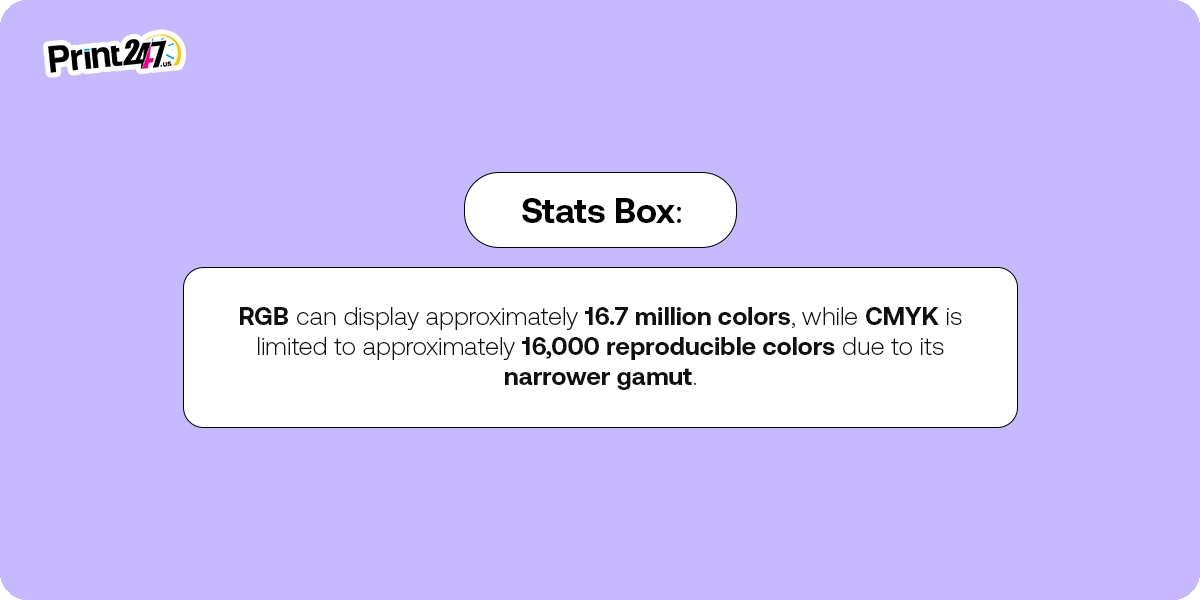

Using this color model, over 16 million colors can be created based on 256 shades of these 3 colors. For generating digital graphics, RGB can produce highly dynamic and vibrant visuals, but not the same color output across devices.

What Does CMYK Stand For?

The CMYK color scheme stands for Cyan, Magenta, Yellow, and Key Black. The inks absorb light as they are laid down, creating a subtractive model. The more ink you use, the less light you will reflect back to your eyes. CMYK is used by printers to reproduce images and brand colors on paper, film, and corrugated.

When to use CMYK?

Use CMYK for any project that will be printed. That includes folding cartons, mailers, mylar pouches, pressure-sensitive labels, stickers, catalogs, and signs. Convert artwork to CMYK early, then choose inks and paper with your print vendor. This keeps color shifts small and predictable.

What are the best file formats for CMYK?

Here is a quick guide. Use formats that lock in CMYK values and support print rules.

PDF/X-1a or PDF/X-4 for press-ready files

AI or EPS for vector logos and line art in CMYK

TIFF for high-quality CMYK images without compression

InDesign packaged files for multi-page items

Avoid sending only JPEG in CMYK for final press unless the vendor approves

In terms of CMYK file formats, PDF is the best option. Due to its printed nature, clients typically request this format when they want to create multiple-page documents like magazines or leaflets. A PDF can also be opened with a number of programs that are suitable for printing.

What Are the Key Differences Between RGB Vs. CMYK?

There are various types of differences between RGB and CMYK. Both models make the colors you see, but they do it in different ways. RGB adds light to reach color on a screen. CMYK uses ink to absorb light on a surface. This core difference limits how bright certain shades can print compared to what you see on a monitor.

Here is the comparison table between RGB vs. CMYK.

Why Do Your Digital Colors Look Different on Print? 5 Key Reasons Explained

In print, digital colors look different because screens use the RGB (Red, Green, Blue) color model which is based on light. However, printers use the CMYK (Cyan, Magenta, Yellow, Black) model based on pigments. Also, some devices have different types of screens and color management software. This is the reason digital colors look different when printed.

When a design moves from light to ink, a few things change. The press, the paper, the finish, and even your file settings affect the result. If you plan for these, you cut color surprises and avoid reprints.

Example: A beverage brand uses a bright teal button on its site. The RGB teal looks electric on a phone. On a CMYK label, it prints as a softer blue-green because the ink set cannot reach the same glow that backlit pixels show.

In the context of CMYK vs RGB, here are some reasons in detail why colors look different on print.

#1 - Different color gamuts between light and ink

Compared to the CMYK format, RGB displays a greater range of colors, including neon-like greens, bright cyans, and deep blues. CMYK systems have a smaller color range since inks cannot emit light. When you export RGB art without converting it to CMYK, out-of-gamut colors will be mapped to the closest CMYK match. That match may look dull. The solution is to convert to CMYK early, use a printer ICC profile, and adjust brand shades to CMYK-friendly values. Develop CMYK builds that pass your proof for a brand palette.

#2 - Paper stock color, texture, and finish change the look

Paper is not the same white across all jobs. Coated sheets reflect more light and hold sharper dots. Uncoated sheets soak up ink and soften edges. Kraft is brown and will mute colors. Gloss adds pop. Matte reduces glare but can lower contrast. Your CMYK values may be correct, yet the surface shifts the look. Ask for swatches of the exact stock. If you print boxes, test on the real substrate, such as SBS board or corrugate. The stock sets the baseline for every color you see.

#3 - Device differences across monitors and presses

Monitors vary in brightness and color. A design team may view the same file on different screens and see different shades. Presses also vary. A digital press on labels prints differently than an offset press on cartons. Wide-format printers for banners have yet another ink set. To reduce drift, calibrate your monitor and use soft proofing with the right ICC profile. On the print side, ask your vendor about their press, ink set, and control targets. That way, you aim at the right result from the start.

#4 - Black builds and rich black vs pure black

On screens, black is the absence of light, so it always looks deep. In CMYK, 100% black alone can look gray on large areas. Many shops use a rich black build, such as C60 M40 Y40 K100 for solids. Text usually stays at 100% K for sharp edges. If you send large black panels as K only, they can look washed out. If you make small text with rich black, it can misregister. Use the right black for each part of the design. Your vendor can share preferred builds for their press.

#5 - Overprint settings, transparency, and color profiles

Overprint and transparency settings in design apps can create surprise gaps or color shifts on press. RGB files with effects like glow or soft shadow may convert into CMYK blends that do not look the same. Mismatched profiles, for example, sending sRGB art into a GRACoL CMYK workflow without conversion, can also shift colors. Keep a single source of truth. Use the same RGB profile across the team during design, then convert to the agreed CMYK profile before final export. Flatten complex transparency where needed.

Source: KDP Community

What's the Best Way to Keep Colors Popping on Print?

Color control is a process, not a one-time step. If you plan ahead and align with your print vendor, your boxes, labels, and signs will match your brand closer, job after job.

Here are some tips in this regard to keep your colors popping on the print.

Convert to CMYK early in the workflow

Do not wait until the final export. Convert working files to the print profile as soon as the layout is set. You can adjust any out-of-gamut colors by hand. This thing keeps late-stage surprises low and saves time on corrections.

Ask for the correct ICC profile and presets

Printers provide profiles for their presses and stocks. You have to load them into Photoshop, Illustrator, and InDesign. Use their PDF presets like PDF/X-1a or PDF/X-4. This aligns your files with how the shop runs color.

Soft proof on a calibrated monitor

Use View settings to simulate the print profile. Keep your monitor brightness near a neutral level. If the soft proof looks dull, that is a sign that the printed result would look the same. Adjust art before sending files.

Choose the right substrate and finish

Coated paper helps with sharp color. Uncoated gives a natural feel. Films on mylar bags can boost saturation. Finishes like gloss UV can add punch. Matte looks premium but reflects less light. Pick based on the brand's need.

Use spot colors for must-match brand tones

If your brand blue is critical and CMYK matches poorly, request a Pantone or custom spot ink. This adds cost but can lock a key tone. Use spot ink on logos or small areas, and keep the rest in CMYK to control budget.

Set black builds the right way

Use 100% K for small text. Use a rich black build for solid backgrounds based on vendor guidance. This keeps type crisp and large areas deep and even.

Request a hard proof or press sample

A printed proof on the real stock shows the final look better than a screen. Many leading suppliers of printing and packaging, such as Print247, offer samples for your products, so that you can check out what they look like before bulk ordering. Approve the proof before the full run. For Christmas labels and boxes, a physical sample reduces risk and aligns teams.

Color control improves when design and print work as one system. Keep profiles aligned, pick the right stock, and proof early. These steps lower risk and protect your brand.

Is it better to print in CMYK or RGB?

It is better to print in CMYK. The reason is that CMYK uses ink to create colors on print while RGB uses light to create colors that include neon and ultra-vibrant tones. If you send an RGB file to the printer, it will automatically convert it into CMYK which will result in muddy or dull colors. So it is always better to print in a CMYK color model.

How to maintain color consistency across all models?

To maintain color consistency across all models, standardize your workflow around a single CMYK color profile. Always use calibrated monitors for accurate viewing. When using PMS (Pantone Matching System), a specific ink formula is used independent of the type of printer.

Final Thoughts

Screen color and print color play by different rules. RGB lights up on a display. CMYK is printed on paper or film and reflects room light. Once you know this, you can plan. Convert early, soft proof, pick the right stock, and ask for proofs. When your next packaging run is ready, partner with a team that makes this easy.

Print247, a top-rated printing and packaging company in Rosenberg, helps brands across the US with custom boxes, mylar bags, labels, stickers, signs, and banners. You get free design support, eco-friendly materials on request, fast shipping, and physical samples for peace of mind. Keep your brand colors steady from phone to shelf with a process that works every time.

FAQs

Is RGB ever okay to send for printing if I am in a rush?

It is better to avoid it. The printing company will convert it to CMYK anyway, which can shift colors without your input. Ask the vendor for their profile, convert to CMYK on your side, and review the result before you send.

Which RGB profile should I design before converting to CMYK?

Most teams use sRGB for web and general work. Some wide-gamut monitors support Display P3. Pick one profile and keep it consistent across the team. When you prepare files for print, convert to the printer’s CMYK profile.

What if my logo has a neon accent that CMYK cannot hit?

Keep the main mark in CMYK for most jobs and reserve a spot ink for key packaging runs or hero signs. You can also define a CMYK-safe alternative for small prints, then use the neon version in digital spaces only.

Do I need different CMYK builds for different papers?

Yes. Coated and uncoated stocks can need different builds, especially for rich black and brand tones. Ask the vendor for coated and uncoated profiles or swatches. Test on the final stock for best results.

Why is my print color not matching my screen color?

The difference between light and ink is the fundamental reason behind it. Modern screens use RGB to project the object while printers use the CMYK model, which creates color by layering ink that absorbs light.

Can I print directly from a PNG or JPEG if it looks fine on screen?

You can, but it is not ideal for the final press. Those files may be RGB and may not include the correct print settings. Export a CMYK PDF/X from your design app with the right profile. This preserves intent and reduces surprises.

What is the best way to preview how my label will look on a pouch or box?

Use soft proofing with the print profile, then request a hard proof or a short sample on the exact stock. For flexible pouches, ask for proof on the same film and finish so you can judge shine and saturation.

.jpg)

.jpg)

.jpg)