14 Key Techniques in Packaging Finishing for Superior Product Appeal

.jpg)

In the packaging world, finish choice holds great importance as it directly affects customer choice. If there are two products sitting side by side on a shelf, which product do you think the customer will choose?

Of course, the one that has a better finishing. Packaging with better finishing looks rich in color and solid in manufacturing. Customers nowadays may not know the print terms, but they feel the difference right away by judging the packaging's look.

It is often the small details on the surface of packaging that push a prospect to order their first item or to reorder more than one. By using custom packaging finishes, you make your product stand out in retail aisles, warehouses, and unboxing videos.

Our blog guides you through real-world packaging finishing options that package buyers, marketers, and print managers use every day. You will learn how packaging coatings and varnishes, textures, and special effects work, where they make sense, and how to pick the right blend for your budget and brand.

What is the Importance of Finishing in Packaging?

Finishing conveys a sensational experience that appeals to both sight and touch. It’s not just a “nice extra” on top of print. It is a key part of how people see and touch your product. Good packaging finishing protects the print, adds life to colors, and supports your brand story at first touch. For example, cosmetic packaging with soft-touch finishing conveys the cream’s smoothness and gentleness on the skin.

Some key roles of finishing in packaging:

- Protects ink from scratches, rub, and moisture

- Adds shine or a soft feel that signals quality

- Helps key elements like logos and product names stand out

- Supports tactile packaging design that people remember

- Helps keep colors stable during shipping and handling

- Supports sustainable packaging finishes when chosen well

You make your packaging work harder without changing the product inside when you combine custom packaging finishes with a clear brand message. The right print finishing methods can lift a good design into something that feels premium, trusted, and worth a higher price point.

14 Key Techniques in Packaging Finishing Explained

Packaging finishing is a combination of processes to enhance the look and feel of a product. There are many ways to finish a box, label, mylar bag, or sign. Each process has its own look, feel, and cost level. Some are focused on protection, like UV varnish protection or anti-scratch coatings. Others are all about impact, like foil stamping techniques, 3D embossing methods, and holographic packaging effects.

You do not need to finish every job. In fact, too many layers can confuse your buyer and raise costs fast. A smart mix of packaging coatings and varnishes, texture, and shine can give you premium print finishes without waste.

These are the most common packaging finishing options buyers use every day. You will learn what each section is, how and why it is beneficial, and when it is worthwhile to invest in it.

#1) Foil Stamping

Foil stamping is a renowned packaging finishing technique that uses heat and pressure to press a metallic foil onto your box or label. It is one of the most trusted foil stamping techniques in packaging. When used on logos or key text, foil stamping for boxes signals a higher tier product right away.

You can use:

- Gold, silver, rose gold, or colored foils

- Gloss metallic or satin metallic styles

- Metallic foil stamping with patterns or holographic effects

Foil works well on rigid boxes, folding cartons, and luxury mailers. When you pair foil stamping with embossing in packaging, you get a strong, layered brand mark that looks and feels special in the hand.

#2) Lamination

Lamination is one of the most critical finishing techniques that adds a thin plastic film over the printed sheet. It creates a strong surface that shields the product packaging from scratches, scuff marks, and tears. This can be gloss, matte, or soft-touch. It gives extra strength and helps with UV varnish protection and scuff resistance.

Common ways brands use lamination:

- Protect busy designs on shipping mailer boxes

- Add matte lamination packaging for a calm, modern feel

- Support anti-scratch coatings on dark colors or large solids

Lamination also helps keep edges from cracking on folds and can extend the life of retail and display packaging, especially for high-touch products. Combined with custom box coatings, it is a practical base layer for long runs.

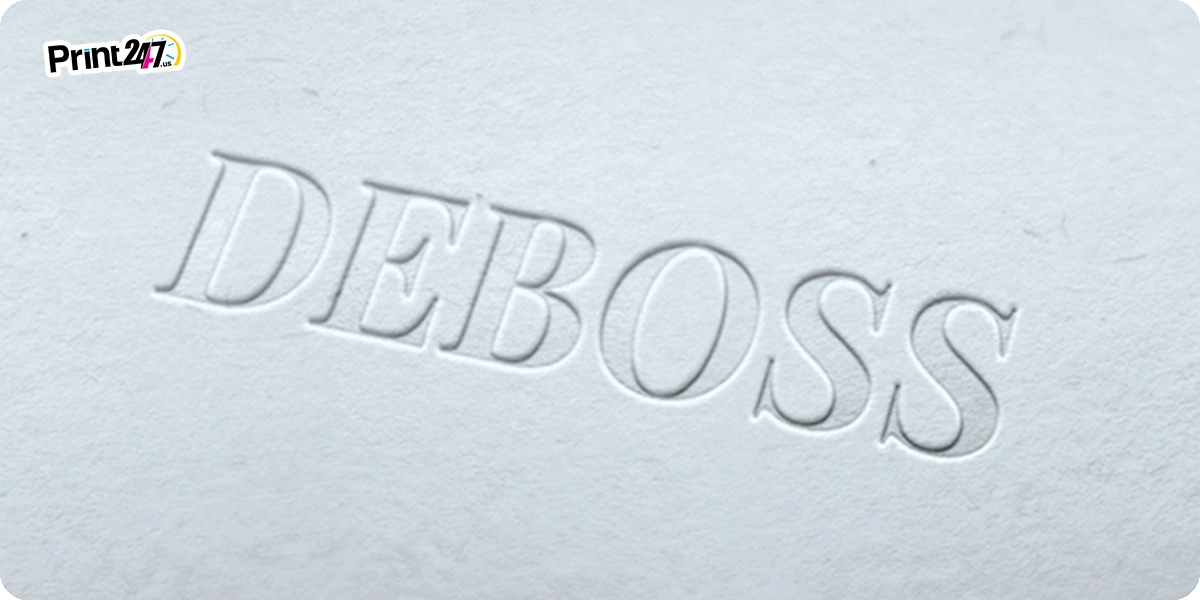

#3) Deboss

Deboss pushes the surface of the board down instead of up. This finishing technique is achieved by a special metal die, which is often made of brass or magnesium. It creates a pressed-in effect that works well with simple logos and clean typography. You see it often in embossing and debossing packaging for wine boxes, skincare, and tech.

When should you use deboss?

- You want a subtle, quiet luxury feel

- The design is mostly flat with one hero mark

- You want contrast without more color

Deboss can be used alone or with foil, and it pairs well with soft touch coating and matte lamination packaging for a rich, understated look.

#4 - Soft-Touch

Soft-touch is the most effective and premium finishing technique in packaging. These finishes are non-reflective and have a matte appearance. It uses a soft-touch coating or lamination to create a smooth, almost “peach skin” feel. This style sends a strong quality signal the moment someone picks up the box.

Soft-touch is ideal for:

- Premium cosmetics and skincare

- High-end tech, phones, and accessories

- Subscription boxes that focus on unboxing

Soft-touch works great with tactile packaging design. Gloss details, foil, or spot UV coating on top of soft-touch can create a sharp contrast and guide the eye to your brand name or product claim.

#5 - Die Cut

Die cutting is a key packaging finishing technique that shapes the board or label using a custom metal die. It is the key step in die cutting packaging and helps your pack stand out even before the graphics speak.

You can use die cuts to:

- Add windows to show the product inside

- Create custom handles or hang holes

- Shape labels to match your logo or product form

Die cutting also supports functional add-ons like tuck locks, inserts, and unique closures. You apply it to a wide range of materials, including cardstock and corrugated board. Combined with custom packaging finishes, it helps you create both structure and style.

#6 - Gloss Coating

Gloss coating is a clear finish that adds shine, reflection, smoothness, and some protection. It can be water-based, UV, or solvent based. Gloss brings out color and is common for FMCG, cosmetics, luxury products, food, and beverage packaging.

Key gains from gloss:

- Strong shelf impact

- Higher contrast in images

- Easier to wipe clean

Gloss combines well with high-gloss UV spots to highlight key areas while keeping cost under control. It is a solid base for many print finishing methods.

#7 - Embossing

Embossing is a renowned print finishing technique that raises parts of the board to create a 3D effect. Embossing in packaging is one of the most loved finishes for premium brands. It works very well with logos, patterns, and short headings.

You can use:

- Single-level emboss

- 3D embossing methods for more depth

- Emboss with foil for richer, premium print finishes

Embossing adds a strong tactile packaging design and helps your brand stay in memory even when the box is gone. If you want to add a premium and luxury touch to your custom packaging, consider embossing.

#8 - Sublimation

Sublimation uses heat to transfer dye into certain materials, such as polyester fabrics and some coated products. In packaging, it is less common for boxes and more common for branded wraps, soft displays, or fabric-based carriers.

When used, sublimation offers:

- Deep, durable color in textiles

- Strong brand image on reusable totes or wraps

- Long-lasting print that will not crack or peel easily

Sublimation can support reusable outer packaging in a broader packaging system, especially in promotions and gift sets. It doesn’t peel, fade, or crack, which makes it highly suitable for various types of materials.

#9 - Spot UV

Spot UV is a type of spot UV coating placed only on selected areas, such as logos, images, or text. It gives a strong gloss effect that stands out from a matte or soft-touch base. It is also an environment-friendly packaging finishing option as the UV coating is solvent-free and cured instantly.

Spot UV is useful for:

- Highlighting product names

- Making small patterns that catch light

- Bringing focus to QR codes or web URLs

When layered over custom box coatings, spot UV gives contrast without adding new colors, which helps with brand consistency and cost control. Choose spot UV for powerful branding in this crowded business environment.

#10 - Matte Lamination

Matte lamination packaging is popular with beauty, wellness, and lifestyle brands that want a calm, modern look. The surface is flat and non-reflective, which makes text easy to read in bright light. It gives a professional and understated look that also resists fingerprints.

Use matte lamination when:

- Your brand style is simple and clean

- You want to avoid glare in stores or photos

- You plan to add gloss, foil, or Spot UV on top

Matte lamination also helps hide small scuffs better than strong glossy varnish finishes, which can show every mark.

#11 - Drip-off

Drip-off finishing technique is also called hybrid varnish. It combines a special dull coating with high-gloss UV in one pass. The gloss “repels” from the dull areas, creating contrast patterns.

Brands use drip-off to:

- Add texture without embossing

- Highlight images or text with gloss

- Keep costs lower than full multi-step gloss methods

It is extensively used for alcohol, high-end gifts, and cosmetic packaging for a luxurious appeal. Drip-off is a smart and cost-effective way to add effect in long-term jobs where small savings add up.

#12 - Holographic

Holographic finishing uses special films or foils to create holographic packaging effects that shift color with light. This is popular in beauty, gaming, CBD, and security-focused packaging.

Holographic layers can:

- Give a futuristic, high-energy shelf look

- Support anti-fake efforts along with codes and seals

- Build strong shelf presence in busy categories

The purpose of holographic finishing is mainly to create a noticeable visual impact, convey luxury, or increase security. When mixed with metallic foil stamping or reverse UV printing, holographic surfaces can send strong visual cues that a product is new, trendy, or limited edition.

#13 - Hot Stamping

Hot stamping is similar to foil stamping but can also include pigment foils, not only metallic. It uses heat and pressure to bond foil to the surface. Companies use these packaging finishing techniques for various types of products, including perfumes, cosmetics, spirits, and specialty foods.

Brands choose hot stamping when:

- They need sharp, crisp detail

- They use specialty foils, like matte pigment

- They want strong shelf presence with simple graphics

For many brands, hot stamping and foil stamping for product boxes feel similar, but your packaging supplier may guide you to the specific tooling and foil that best fits your board and run size.

#14 - Aqueous Coating

Aqueous coating is a water-based finish that dries quickly and adds light protection. It is one of the most common packaging coatings and varnishes used today. It’s non-toxic and water based that makes it highly suitable for food products.

Aqueous options:

- Gloss, satin, or matte

- Fingerprint resistance

- Food-contact friendly in some grades

It is often chosen by brands looking for eco-friendly varnishes that still protect the print and support good run speeds on press.

Sustainability Options in Packaging Finishing

More brands now review not only the board and ink but also the finishing when they set sustainability goals. Your choice of packaging coatings and varnishes, laminations, and foils can affect recyclability and carbon impact. Choosing sustainable packaging finishes is a smart step that buyers and retailers will notice.

Biodegradable Coatings

Biodegradable or water-based eco-friendly varnishes are designed to break down faster or be easier on recycling streams. They avoid heavy solvents and often work well with paper-based packs.

They are useful when:

- You want to keep mono-material packaging

- You want to avoid plastic films where possible

- You want a more natural, paper-forward look

Biodegradable coatings can still offer good rub resistance and soft sheen, so you do not have to give up all surface quality.

Recyclable Laminates

Traditional lamination can block fiber recovery, but newer recyclable laminates aim to reduce the problem. Some are designed to separate more easily in the recycling process, and some use thinner films.

Brands look at:

- Film thickness and type

- Compatibility with local recycling streams

- Balance between anti-scratch coatings and eco goals

By picking smarter laminates and sustainable packaging finishes, you can keep strong shelf appeal while showing clear care for the environment.

Comparison of Key Packaging Finishing Techniques

There is no single “best” finish. You need to consider your brand, your budget, and your supply chain when choosing the right mix. A brief, clear comparison will help you communicate effectively with your printer and protect yourself from over-specifying.

Below are simple matchups that B2B buyers often ask about when reviewing custom packaging

Matte vs. Gloss Finishes

Matte and gloss are two basic surface choices that change how people read your design.

The matte finish is the default choice for many lifestyle brands looking to maintain a quiet feel. Gloss is common in FMCG, snacks, and lower-priced items where strong glossy varnish finishes help products stand out quickly.

UV Coating vs. Aqueous Coating

Both UV and aqueous belong to packaging coatings and varnishes, but they act very differently.

UV is suited when you need strong gloss and UV varnish protection. Aqueous is the daily driver, especially for brands focused on cost control and speed.

Foil Stamping vs. Hot Stamping

Many people use these terms in similar ways. In practice, both apply foil with heat and pressure, but options and tooling can differ.

When you ask your packaging supplier about foil stamping techniques, share your board type and run size. They will guide you to the exact process, but both options signal high value.

Embossing vs. Debossing

While both processes are capable of embossing and debossing packaging, their feel is different.

Use embossing when you want a bold tactile logo. Use debossing when your brand voice is quiet, modern, and detail focused.

Screen Printing vs. Digital Printing

Both can work in labels and specialty packaging, but they serve different needs.

Many brands now blend the two. They print digitally, then add screen-printed custom box coatings or tactile varnish where needed.

Final Thoughts

In a world where many products look similar, the right packaging finishing can become the extra push that wins shelf space, clicks, and repeat orders. When you use print finishing methods in a smart way, your boxes, labels, and mylar bags do more than just hold a product. They tell buyers your brand cares about detail, quality, and customer experience.

The Print247 team is a great choice if you are looking for packaging coatings and varnishes, custom packaging finishes, and real-world business-to-business needs. We offer free design support, eco-friendly materials, prompt shipping, and physical samples so you can touch and feel finishes before ordering.

From embossing in packaging to foil stamping for boxes, spot UV, and soft-touch, our team can help you set the right mix for your market and budget. When your packaging feels as good as it looks, your brand stays in mind long after the box is opened.

FAQs

What is the difference between embossing and debossing?

Embossing raises the design above the surface, while debossing presses it down into the board. In embossing debossing packaging, embossing feels more bold and tactile, and debossing feels more subtle and refined. Both can pair with foil stamping for boxes or Spot UV for extra impact.

How does foil stamping affect packaging?

Foil stamping adds a bright metallic or pigment layer to logos, borders, or text. This process makes key elements stand out from the rest of the design and signals a higher product tier. When used on carton faces and brand marks, foil stamping for boxes quickly draws attention in busy retail spaces.

Is die cutting considered a finishing technique?

Yes. Die cutting packaging is a core finishing step. It shapes the box or label and can add windows, handles, or special edges. Die cutting affects both the look and function of the pack and often works together with custom packaging finishes like lamination and Spot UV.

What are the most sustainable packaging finishes?

More brands now ask for sustainable packaging finishes that keep packs recyclable. Popular options include water-based eco-friendly varnishes, low-VOC coatings, and thinner, more recyclable laminates. The goal is to keep strong packaging coatings and varnishes while reducing plastic and keeping mono-material structures where possible.

How to choose between matte and gloss lamination?

Choose matte lamination packaging when you want a calm, modern look, less glare, and better hiding of fingerprints. Choose gloss when you want strong shine and high color depth. Many brands mix both by using matte lamination overall and high-gloss UV or Spot UV in key areas for focus.

What role does UV coating play in durability?

UV coating is a hard, cured finish that adds strong UV varnish protection. It resists rub, scratches, and handling better than many basic coatings. This makes it useful for high-touch packs, shipping-heavy items, or premium print finishes that must stay clean and sharp across long supply chains.

Are there cost-effective finishing options for small businesses?

Yes. For small brands, simple print finishing methods, such as aqueous gloss, satin varnish, or light custom box coatings, can be used to protect print without requiring expensive equipment. The packaging of limited SKUs, hero products, or gift sets can be customized with short-run digital foiling, spot UV, or simple embossing.

How do holographic finishes help with anti-counterfeiting?

Holographic packaging effects are harder to copy than plain print. Complex patterns, shifting colors, and custom metallic foil stamping make fake packs easier to spot. When combined with QR codes, serial numbers, or reverse UV printing, holographic elements help brand owners protect products and reassure buyers across markets.

.jpg)

.jpg)

.jpg)