What Are Standard Box Sizes and Packaging Styles in the USA in 2026?

.jpg)

Standard box sizes in the USA vary by style, shape, shipping method, inner inserts, and fragility. Some examples include 8x6x4 inches for small items, 12x9x6 inches for medium items, and 18x18x16 inches or 24x18x18 inches for larger shipments.

If your team picks and packs orders every day, the right box size is a big deal. It touches freight, storage, and returns. A packaging box that is too large drives dimensional weight. A box that is too small crushes the product and slows your line.

In the coming years, brands that standardize a short list of shipping box sizes and mailer boxes will be able to move orders faster and spend less per order. We have written this blog for print buyers, operations managers, and e-commerce leaders who need easy-to-understand answers about standard box sizes. You will see common box dimensions, a clean size chart for carriers in the USA, and handy tips for measuring inside box dimensions the right way.

A Detailed Standard Box Size Chart for Daily Shipping and Storage

When it comes to standard box sizes, we categorize them by their daily use and the type of product being packed in them. It's essential to understand these sizes and dimensions to launch the product successfully.

All sizes below are inside dimensions in inches. Use length by width by height in that order. When you plan a custom packaging run, give your vendor inside measurements so the product and insert fit as planned.

Here is a detailed standard box size chart.

The US packaging market is valued at USD 208.98 billion in 2025, expected to grow at a CAGR of 3.98% to reach USD 254.01 billion by 2030, driven by e-commerce and sustainability demands. Source: MordorIntellegance

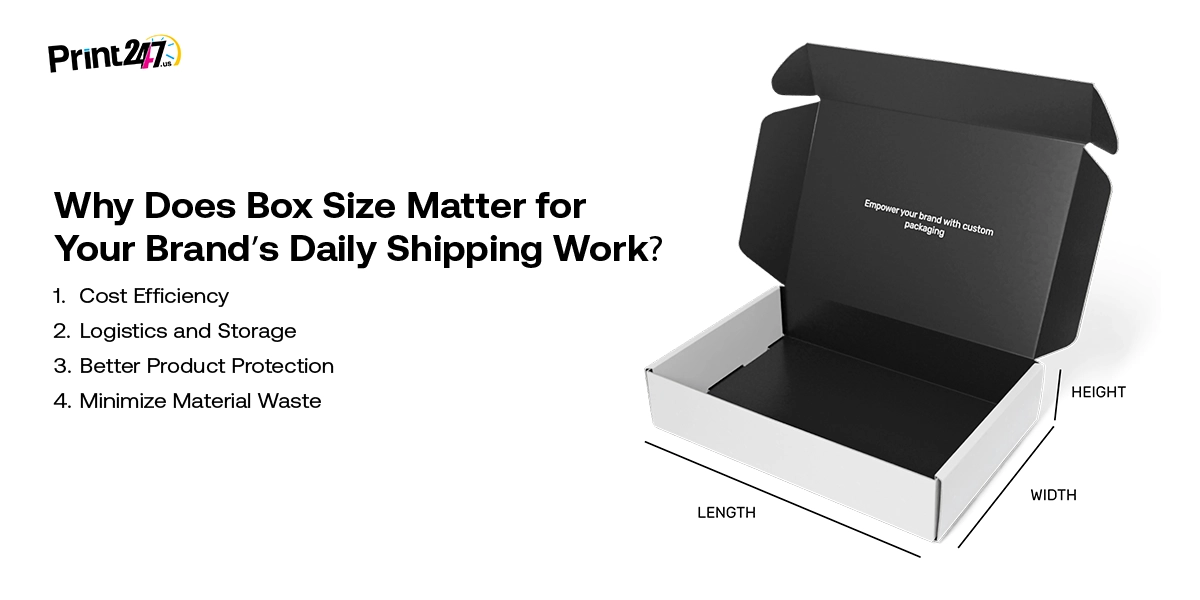

Why Does Box Size Matter for Your Brand’s Daily Shipping Work?

A shipping box is more than a piece of cardboard. It is a cost driver, a storage unit, and a guard for your product. When you choose the right box size, it lowers the bill, protects the item, and speeds the packing bench. In the event that you choose the wrong box, you will be charged air shipping fees and will be faced with avoidable returns.

A shipping box is more than a piece of cardboard. It is a cost driver, a storage unit, and a guard for your product. When you choose the right box size, it lowers the bill, protects the item, and speeds the packing bench. In the event that you choose the wrong box, you will be charged air shipping fees and will be faced with avoidable returns.

Here are some reasons that highlight the importance of knowing the right box dimensions.

#1 - Cost Efficiency

Dimensional weight is the silent fee that shows up when a carton is big and light. A 12”×12”×6” box filled with air can cost more than a smaller box with a heavier item. When the shipping box sizes match the product footprints, the billed weight tends to be closer to the actual weight. There is no need to change carriers in order to cut shipping costs this way.

#2 - Logistics and Storage

The use of common box sizes helps your warehouse run more smoothly. There is room for a short list of cartons on the racks and in the pick faces of the pick machine. Pallets build tight. It is less frequent for you to swap out totes. It is easier for new team members to learn at the pack bench because there is less guesswork. Thus, picking per labor hour can be improved and overtime can be reduced during peak hours.

#3 - Better Product Protection

If the corrugated box is tightly fitted with the right insert, rattles and crushes can be prevented. The right custom box guards corners and keeps pressure off lids, pumps, and seals. In this case, there is no need to fill the void. That saves time and keeps the unboxing simple for the customer. Fewer returns show up, which protects the margin.

#4 - Minimize Material Waste

When you choose the right custom packaging box size, you trim raw material use and reduce vacuum fill. This is good for spending and for your sustainability goals. Buyers like a neat, right‑sized packaging solution that is easy to recycle. Your brand looks careful and efficient, not wasteful.

What Are Common Product Box Sizes Across Retail and E‑commerce?

Most common product sizes strategically fall into small, medium, and large categories. These sizes range from 6” x 4” x 2” for small boxes, to 10” x 8” x 4" for medium boxes, and 14" x 12” x 8” for the large boxes category.

Bridging the gap between logistical efficiency and brand perception is only possible when you select the right product box size. Especially for retailers and e-commerce businesses, choosing the right packaging box size directly reduces shipping costs by avoiding expensive dimensional weight (DIM Weight) supercharges from carriers like UPS and FedEx.

Most products land in a few proven size ranges. If you start with these ranges, you will get close on your first pass. Always confirm with a sample, since inserts, pumps, and lids change the height and the fit.

CBD Boxes

CBD brands often ship small, fragile units like tinctures and salves. A 30 ml dropper bottle fits well in a tuck‑end box around 1.375 x 1.375 x 4.25 with a simple insert to hold the neck. A 1 oz jar fits a 2.5 x 2.5 x 2.5 paperboard box. For pre‑rolls, a slim 3.5 x 2 x 0.75 works well. Use 18 to 20 point paperboard for a clean print, and add a child‑safe outer if you ship to states that require it.

Soap Boxes

Bar soap sizes vary by mold and cure. A 4 oz bar often sits well in a 3.75 x 2.75 x 1.25 sleeve or straight tuck. A 5 oz bar may need about 4 x 3 x 1.5. If scent is part of the sale, add a die‑cut window. Kraft paperboard gives a natural look. If you sell in wet areas, use a small vent hole to let moisture escape so the box does not soften.

Cosmetic Boxes

Cosmetic units like lipstick, mascara, and jars need slim packaging boxes to prevent scuffing. A lipstick box around 1 x 1 x 3.25 is common. Mascara wands often fit a 1 by 1.5 x 6 box. A 30 ml serum dropper works in 1.5 x 1.5 x 5. A 50 ml jar fits a 2.75 x 2.75 x 2.25. For premium print, use coated paperboard and keep small type above 6 pt for legibility.

Custom Rigid Boxes

Adding rigid setup boxes to a setup adds extra weight and gives it a more premium appearance. A candle box around 3.5 x 3.5 x 4 with a foam or pulp insert is a strong pick. Gift sets and small devices often use a two‑piece rigid box around 7 x 4 x 1.5. Chipboard weight runs 80 to 120 point for strength. Magnet closures feel nice but add cost. A ribbon pull or thumb notch can save on hardware and still open smoothly.

Mailer Boxes

Mailer boxes are the workhorse for DTC brands and subscription box programs. A simple set of 6×4×2, 9×6×3, 10×8×4, and 12×9×4 covers many SKUs. Use E‑flute for light items, and B‑flute or C‑flute for heavier kits. An interior with printed labels makes it easier to unbox without having to add new product labels on the outside. They also fit many carrier bins, so speed is improved.

Display Boxes

Counter displays, often called PDQs, hold small packs at checkout or on shelves. A compact counter tray around 8 x 5 x 7 with a tear‑away front lets shoppers grab single units. A narrow 7 x 3 x 7 display works for sticks, pouches, or slim tubes. Make sure the back panel is tall enough to show the logo above the shelf line.

Folding Cartons

Folding cartons are common in retail for light products. Use straight tuck for clean lines or reverse tuck for speed. A small bottle often uses 2 by 2 by 5. A slim device might use 4 by 2 by 6. If you hang on pegs, add a euro slot. Keep a small glue flap and check that auto‑bottoms fit your conveyor height.

Corrugated Boxes

For outbound shipping, a short list of corrugated box sizes keeps things simple. 12×9×4 handles soft goods and kits. 12×12×6 and 14×10×6 cover mid‑size products. 16×12×8 and 18×12×12 manage bulk orders or multi‑unit picks. If you're handling heavy liquids or glass, step up to a stronger board. When using a subscription box, keep the weight within your rate break.

Paperboard Boxes

Paperboard works for lighter items like snacks, cosmetics, and sleeves. A candle sleeve near 3.25 x 3.25 by 4.25 lets the jar show through. A snack carton around 7 x 2 x 8 fits small bags. Coated SBS gives bright print. Uncoated Kraft supports an eco‑friendly look while staying sturdy.

70% of US consumers prefer packaging with clear sustainability labels, while 39% have switched brands for better sustainable options. Source: Shorr

What Are Standard Shipping Box Sizes?

When it comes to shipping box sizes, the values vary. However, typically most common shipping box sizes include small cubes like 4 x 4 x 4 inches, 6 x 6 x 6 inches, or 8 x 6 x 4 inches. Medium shipping box dimensions include 12 x 12 x 6 inches, 16 x 12 x 12 inches, or 10 x 8 x 6 inches. Larger shipping box sizes include 18 x 18 x 16 inches or 24 x 18 x 18 inches.

We have included the following information in table form to make learning about shipping box sizes easier for you:

Using a shipping box that is too large can increase the dimensional weight cost. Choosing a smaller box that fits your product plus 1 to 2 inches pof adding is a wise decision.

How To Measure A Box Size Correctly?

Measurement science holds great importance in our daily lives. Measure any box correctly for your product, protect products, save shipping costs, and maintain a professional presentation. To measure a box size correctly, it is important to record dimensions in a specific order: Length x Width x Height (L x W x H).

Here's a step-by-step process on how to measure a box easily.

Step #1 - Identify the length (L)

Find the longest side of the box to identify the length of the box. Always start with the length. Use a measuring tape and measure from one outer edge to the opposite outer edge.

Step #2 - Identify the Width (W)

Find the shortest side of the box to identify the length. Now measure this from the front outer edge to the back outer edge.

Step #3 - Identify and Measure the Height (H)

Now measure the height of the box. It is the vertical distance between the box bottom and to the top opening. If there are flaps in the box, ensure they are closed or folded down to get the accurate height.

Step #4 - Measure Outer Dimensions (OD)

Always measure the outside of the box for shipping and logistics. This includes bulging sides and thick cardboard layers, as carriers care about how much space the box occupies.

Step #4 - Calculate the Volume of the Box (V)

This is the final and most important step in measuring the box sizes correctly. It is important to determine the volume of the box in order to determine how the product would fit in the box. To calculate the volume, multiply the length (L), width (W), and height (H).

Here’s the formula:

Volume = Length x Width x Depth

Always verify and double-check numbers to get accurate data for your labels.

Final Thoughts

Box size decisions add up. A small change can lower billed weight, free shelf space, and make packers quicker. It can also make your brand look sharp when the customer opens the shipping box.

If you want an easy packaging solution that works day after day, talk to Print247. We help U.S. brands set a sensible box plan, match SKUs to standard box sizes, and print custom packaging that fits. You get free design support, eco‑friendly materials, fast shipping, and physical samples before production.

Whether you need corrugated boxes, mailer boxes for a subscription box line, folding cartons, custom rigid boxes, labels, stickers, signs & banners, or mylar bags, our team will help you choose the right box size and the right print setup. Your operations will run smoother and your shipping costs will stay fair.

FAQs

What sizes do shipping boxes come in?

There are different sizes of shipping boxes. The sizes range from tiny jewelry boxes of 4x4x4 inches to large, bulky boxes of 36x24x12 inches. Additionally, there are medium boxes available in sizes 12x12x12 inches.

Why does box size matter so much for business shipping?

Carriers bill by the higher of actual weight or dimensional weight. A box that is bigger than needed creates extra volume and a higher billed weight. A right box reduces cost, protects the product, and speeds up packing. Over the course of a year this can save a lot of money.

What are the standard box dimensions most brands keep in stock?

Many teams keep a core set that covers most orders. Popular sizes include 6×4×2, 8×6×4, 9×6×3, 10×8×4, 12×9×4, 12×12×6, 14×10×6, 16×12×8, and 18×12×12. This mix handles small parts, soft goods, and bundles. Add one or two custom sizes for your top movers.

How do I determine packaging dimensions the right way?

Measure inside the box, not outside. Record length by width by height. Measure the product with any caps or pumps and add space for inserts or wraps. Make a white sample and test with the real item. Then run the box size through the carrier rate tools to confirm it will not spike costs.

Why should we choose custom boxes instead of pre-made ones?

Custom boxes match your product footprint, so you use less filler and get fewer returns. You can print your logo, color, and instructions right on the box. Custom sizes also help control dimensional weight and shelf space. Off‑the‑shelf can work for tests, but most brands save more with custom over time.

What are the standard Amazon box sizes for sellers sending stock?

FBA allows many sizes as long as they meet weight and packaging rules. Sellers often use 9×6×3 and 12×9×4 mailer boxes for single units, then a 16×12×8 or 18×12×12 shipper for multi‑packs. Always check current FBA prep guidance for labels, poly, and inserts so your shipment checks in fast.

What is the most common shipping box size in U.S. e‑commerce?

You will see 9×6×3, 10×8×4, and 12×9×4 very often because they carry a wide range of goods without tripping the dimensional weight. For bulk orders, 16×12×8 is a frequent choice. These standard box sizes stack well, fit common shelves, and keep the unboxing clean and simple.

.jpg)

.jpg)

.jpg)