A Guide to Understanding Mylar Bag Thickness Options

.jpg)

Mylar bag thickness affects puncture resistance, barrier performance, and shelf life. For most commercial dry foods, a 3.5 to 5.0 mil film gives the best balance of cost and protection. Use 5.5 to 7+ mil for sharp items, long-term storage, or industrial parts where extra puncture resistance is needed.

Packaging teams and procurement managers know that small choices add up. When you buy Mylar bags in bulk, the chosen mylar bag thickness changes product protection, handling, waste rates, and total landed cost. Thinner film cuts material cost but raises the chance of punctures, moisture ingress, and customer rejects. Thicker film raises cost per bag but reduces claims, replacements, and repacking time.

We have written this detailed guide for brand teams, co-packers, and packaging engineers. It explains how mylar thickness is measured, why the film structure matters more than a single number, and how to match film choice to product type and storage conditions. Our focus is on real-world performance and risk control so your brand can reduce returns and scale without surprise failures.

What are Mylar bags and why does thickness even matter?

Before you know deep about their thickness, first understand what are Mylar bags in detail.

Mylar, in packaging language, usually means BoPET (biaxially-oriented polyethylene terephthalate). In most cases, mylar bags are made up of a mix of PE, PET, and VMPET. The polyester gives strength and dimensional stability. A thin layer of aluminum or a high-barrier coating delivers light, oxygen, and moisture blocking. The layers of the bag are combined to create a bag widely used in the food and electronics industries, as well as the industrial markets.

Mylar pouch thickness matters for several linked reasons:

Barrier performance does not scale in a straight line with thickness. A thin film with a high-barrier coating can block oxygen as well as a thicker, lower-barrier laminate. What changes most with thickness is mechanical resistance to puncture and tear.

Handling and automation. Heavier film feeds differently in automated filling lines and heat sealers. Thicker films can improve seal durability but may need different sealing parameters and tooling.

Shipping risk. If your goods are palletized, stacked, or subject to rough handling, thicker films reduce pinholes and seam failure. For sharp or pointy products, the thick film reduces puncture claims in transit.

Regulatory and quality concerns. For food and medical goods, film structure affects cleanliness, residual migration, and performance in validated storage. Some sectors expect documented test results, not only a mil number.

For brands, thickness is a lever to lower product loss and protect brand reputation. The thickness you select should take into account the following factors: product fragility, storage duration, environmental conditions, and the acceptable product loss rate per thousand units.

How is Mylar bag thickness measured? The mil vs the micron

We can measure mylar bag thickness in two common units: mil and micron. You should know both and how to convert, because packaging suppliers and spec sheets may use either.

Mil: A mil is one thousandth of an inch (0.001 inch). It is the standard in North American packaging specs. When a supplier lists 4.5 mil, that is 0.0045 inches of film.

Micron: A micron, or micrometer, is one millionth of a meter. It is used widely by international film makers and converters. 1 mil equals 25.4 microns.

Practical conversion helps. For example:

2.0 mil ≈ 50.8 microns

4.5 mil ≈ 114.3 microns

7.5 mil ≈ 190.5 microns

Why units and tolerance matter in contracts?

It is important to include nominal thickness and tolerances in a specification. It is common for films to differ by a few microns during extrusion and lamination. If your spec calls for 4.0 mil ± 0.2 mil, those tolerances translate into performance variances. If the SKU is critical, thickness verification should be required on the initial run or a method of acceptance should be provided.

Thickness is not the only performance metric. Focus on related lab data.

Common tests you should request:

OTR (oxygen transmission rate)

MVTR (moisture vapor transmission rate)

Seal strength and peel tests

Puncture resistance and Elmendorf tear for mechanical durability

If your filling operation uses automated vacuum or gas flush, ask suppliers for run samples so your engineers can dial sealing and feed parameters before a bulk run.

Mylar bag thickness chart

Here’s the mylar bag thickness chart or table.

Common Mylar bag thicknesses and their best uses: a detailed breakdown

Choosing the right Mylar bag thickness is crucial for ensuring that your products stay fresh, protected, and ready for use. The right fit for your product range depends on mylar bag size and thickness. A bag's thickness determines its durability, flexibility, and resistance to environmental damage.

To make the information easier to consume, we are going to share a list of typical thickness ranges below, along with how they perform in practice. This will be particularly helpful in choosing a particular Mylar bag thickness and what to test before purchasing a full-scale product.

Lightweight Mylar bags (2.0 - 3.0 mil)

Lightweight Mylar is thin (2.0 to 3.0 mil) and a cost effective option. Most brands use it when the packed item is smooth, non-abrasive, and will not be handled roughly. In food packaging, these films work where storage is short and oxygen absorbers or vacuum packing add barrier value.

Performance notes:

Flexible films are ideal for automated machines when applying tight folds or small fills.

Films with metallized layers are reasonable against light and moisture, but mechanical protection is limited.

Good for short runs, sampling, retail inner packs, and when outer cartons provide physical protection.

Risk and mitigation of these lightweight Mylar pouches:

Avoid items with sharp edges or long warehouse storage.

Combine with sealed, rigid outer packaging for transit.

Test seam strength and drop handling during pilot runs.

Standard / medium-duty Mylar bags (3.5 - 5.0 mil)

The thickness of standard or medium-duty Mylar bags ranges from 3.5 mil to 5.0 mil. This range is often the default for commercial food packing. Due to its durability and cost-effectiveness, it is widely used for emergency food, bulk dry goods, and retail-oriented bulk packaging.

Why do brands pick this thickness range?

It reduces puncture events in normal handling and transit.

It remains flexible enough for many automated filling lines.

It supports a reliable heat seal with good peel and tensile strength.

Typical applications and buyer checks

Long-term storage of rice, wheat, and other dry grains, usually with oxygen absorbers.

Beans, legumes, and larger-volume coffee and tea packing.

Archival protection for printed material when humidity control is in place.

Request OTR and MVTR data for the laminate you plan to use before scaling. Check the integrity of packages by conducting sealing trials and drop tests. In case you need to display your product at retail, consider gusseted or stand-up Mylar bag designs.

Heavy-duty Mylar bags (5.5 - 7.0 mil)

Mylar bags with a thickness of 5.5 to 7.0 mil are an effective choice for the products that are sensitive or need long term storage. Heavy-duty films add stiffness and puncture resistance. Their usage is best suited to products with points, edges, or that will be stacked and moved frequently.

Core advantages of Heavy-duty Mylar bags

This heavy-duty Mylar bag thickness offers a better puncture and tear resistance in the real world. It has more robust performance when oxygen absorbers or vacuum are used that reduces seal failures. Greater confidence in multi-year storage when combined with proper barrier layers.

Suggested uses

Freeze-dried meals in original packaging where mishandling is possible.

Electronics or hardware that require moisture protection and mechanical strength.

Medical devices where barrier integrity over time is critical.

For quality control precautions, always verify lamination adhesion to ensure layers do not delaminate under storage stress. Test heat seal parameters and monitor for cold seals.

What is the best mylar bag thickness for food storage?

The recommended mylar bag thickness for food storage is 5 to 7 mil. It is ideal thickness as it provides excellent barriers against all the factors that can spoil the food including moisture, light, and oxygen. Some brands use 3.5 to 4 mils for short term food storage. This mylar bag thickness level is also recommended for less sensitive food items.

Extreme-duty Mylar bags (7.5 mil and above)

A heavy-duty Mylar bag (7.5 mil or greater) is essential for the long-term storage of sensitive or heavy products that require maximum protection against physical damage and environmental factors. Designed for industrial and archival purposes, these films can be used in a wide range of applications.

Where Extreme-duty Mylar bags serve best?

Heavy mechanical parts where metal-to-film contact could puncture standard films.

Evidence storage or archival uses where tamper resistance and physical longevity are required.

Military, aerospace, or high-value electronics requiring the highest puncture margins.

It is a good idea to check the capability of your sealing equipment with heavy films. For heavy loads, confirm that closures and seals meet your drop and vibration profiles. Thicker film improves puncture resistance but does not guarantee a lower oxygen transmission rate. Ask your Mylar packaging supplier for OTR and MVTR data for the exact laminate you plan to purchase.

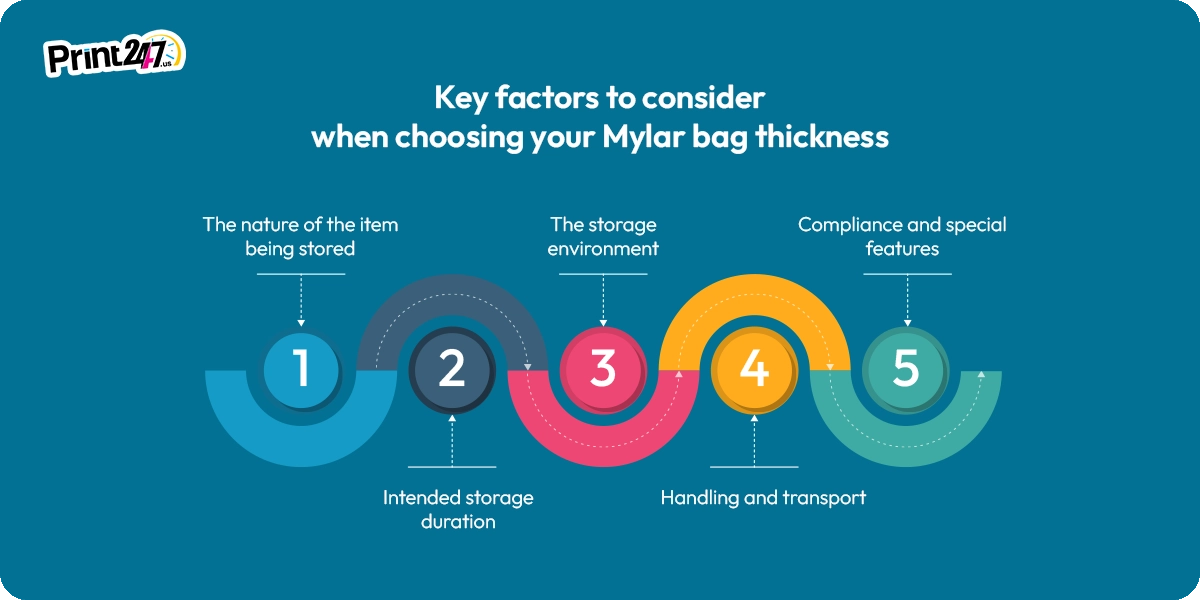

Key factors to consider when choosing your Mylar bag thickness

When selecting a Mylar bag thickness, it is important to take into account the items being stored, the length of storage, handling and environmental factors, as well as the cost. Choosing the wrong thickness can lead to food spillage, wasted money, and potential health risks.

Here are factors you a brand should consider when choosing the thickness for your Mylar bag.

Factor #1 - The nature of the item being stored

Smooth powders and finished baked goods behave very differently from dried pasta or metal fasteners. Sharp corners and abrasive particles concentrate stress on the film. When planning mixed SKU runs, plan by the most demanding SKU rather than the average. Small parts with a high value should be cushioned with inner foam or inner cushions in addition to heavier films.

Factor #2 - Intended storage duration

The product storage duration also affects the Mylar bag thickness decision. Short shelf storage needs less mechanical reserve. Multi-year storage requires higher safety margins, especially when humidity or temperature swings are likely. If you use oxygen absorbers, pair them with a film and seal process that maintains absorber effectiveness over the intended storage period.

Factor #3 - The storage environment

A high level of humidity can lead to hydrolytic effects on certain products and will put a strain on the seals. The presence of UV or light requires the use of layers that are metallized or opaque. Whenever shipping routes include high-heat areas, it would be advisable to test the film and seal samples at elevated temperatures whenever possible.

Factor #4 - Handling and transport

There are several factors to consider, including container stacking, pallet strain, and manual handling. A film that performs well on the production line may fail in transit if corners are cut during palletization or if protective outer cartons are not used. Make sure your outer packaging is puncture-resistant or protective when delivering last-mile orders via e-commerce.

Factor #5 - Compliance and special features

Compliance has a special role in deciding Mylar bag thickness. For that you should check with the Mylar packaging supplier whether child-resistant closures, anti-static layers, or tamper-proof seals are available. If the film batch is made up of food-contact materials, you should request migration data, regulatory compliance statements, and lot traceability.

Where to buy high-quality Mylar bags?

Buy high-quality Mylar bags from the leading packaging supplier, Print247. We provide eco-friendly packaging solutions with clear material data and free design support for bulk orders. Our team provides physical samples for line testing and assists with sealing and drop tests before production begins. We support custom runs with clear lead times and shipping options if you need child-resistant pouches or pre-printed, machine-ready rolls.

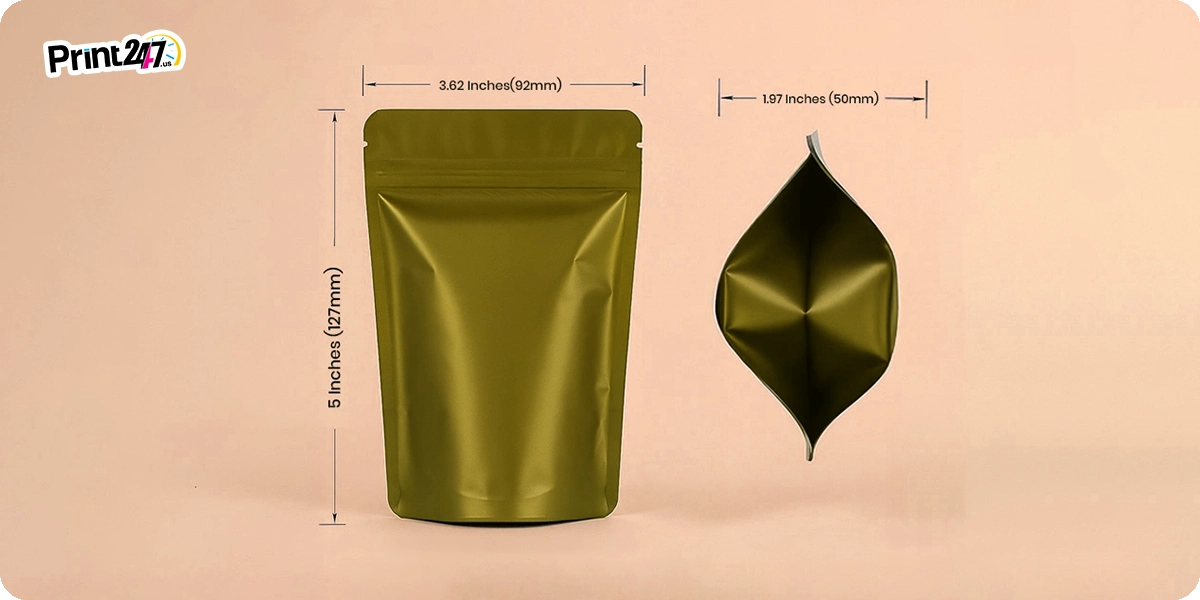

Here’s more detail about our Mylar bags.

Final Words

Mylar bag strength or thickness is a practical method you can use to control product risk, but it is not a standalone solution. Besides the film structure and lamination quality, the strength of the seal, and the use of oxygen absorbers and vacuums are equally important. An economical medium-duty film with a mil thickness of 3.5 to 5.0 meets the demands of most packaging lines. When you need extra mechanical protection for your products or logistics, choose heavier films.

If your brand needs a supplier that supports design, samples, and documented material specs, Print247 offers eco-aware options, free design support, fast shipping, and physical samples so you can test before committing. For seasonal or retail-ready packs, we also provide Christmas Mylar bags and all types of custom product boxes to keep your brand consistent across packaging types.

FAQs

Can I reuse Mylar bags of different thicknesses?

Yes, but with limitations. Reused Mylar bags must be intact, clean, and resealed correctly. Thicker films tolerate reuse better because seals and film handle repeated stress. For food or regulated goods, reuse may be restricted by hygiene rules.

Does a 7 mil bag block twice as much oxygen as a 3.5 mil bag?

Not necessarily. A laminate's design and barrier coatings have a greater impact on oxygen blocking than thickness alone. The performance of a 3.5 mil film with a metallized barrier may be better than the performance of a thicker film with a lower barrier. Don't equate thickness with oxygen performance, but instead request OTR values from suppliers.

Can a mouse or rat chew through a thick Mylar bag?

Rodents can chew many materials. They chew slower when the films are thicker, but they are not fully prevented from doing so. To prevent rodent infestations, use thicker bags along with rigid outer containers, sealed pallets, and pest control in the warehouse.

Do I need a thicker bag if I am vacuum sealing?

Vacuum sealing reduces oxygen but increases tension on the film during processing. Thick mylar sheets handle the mechanical stress and reduce risk of pinholes during vacuum. If your product has edges, use heavier film or add an inner liner to prevent punctures during vacuuming.

How can I tell the thickness of a Mylar bag if it is not labeled?

Measure the caliper with a micrometer in microns and convert to mils (1 mil = 25.4 microns). If you do not have equipment, request a sample and an MDS or a certificate of analysis from the supplier. For critical SKUs, include thickness and tolerance on the PO to avoid surprise batches.

Is it better to double-bag with thinner bags or use one thick bag?

The effectiveness of each strategy depends on the cost, labor, and risk involved. The double-bagging method adds redundancy and can be more cost-effective if thin films are less expensive. A thick bag reduces points of failure and labor. Trial both methods and measure failures per thousand units.

.jpg)

.jpg)

.jpg)