6 Types of Blister Packaging in the Pharmaceutical Industry

.jpg)

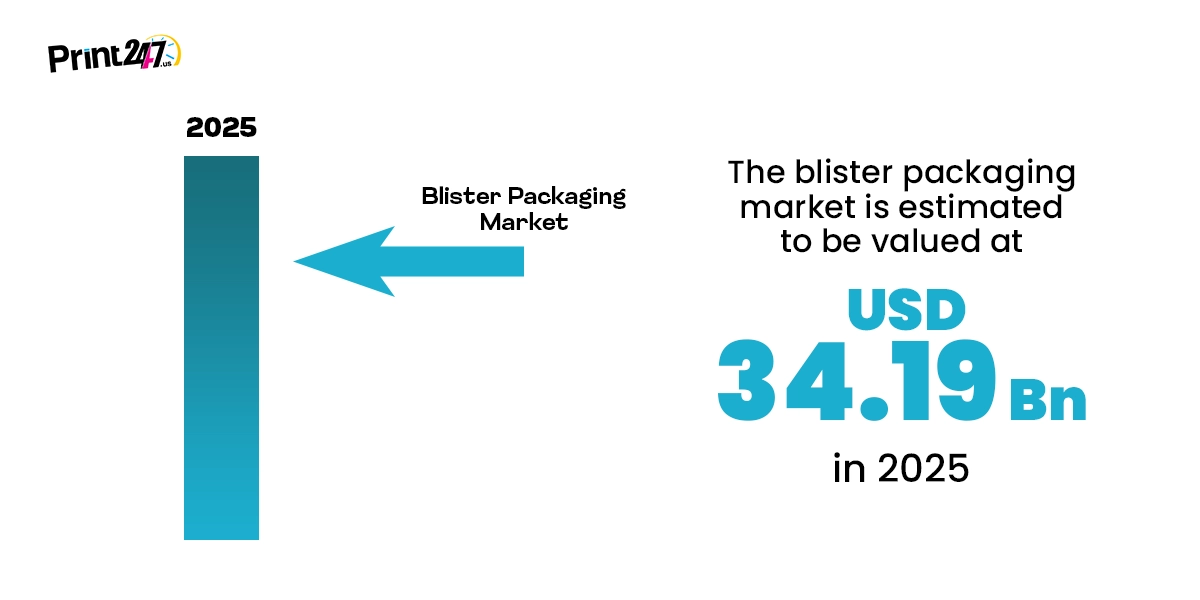

The pharmaceutical industry has seen immense growth over the years as the market faces the highest competition, and some regulatory requirements also evolve with the pharma companies relying more on taking protective measures. Generally, more and more pharma companies are cognizant of the blister pack designs that align with current demands. Therefore, Blister packs have been there for the fast-growing packaging options for the pharmaceutical industry. The enormous popularity in just pharmaceutical blister packaging of North America has reached to a size of USD 10.63 Billion in 2025,

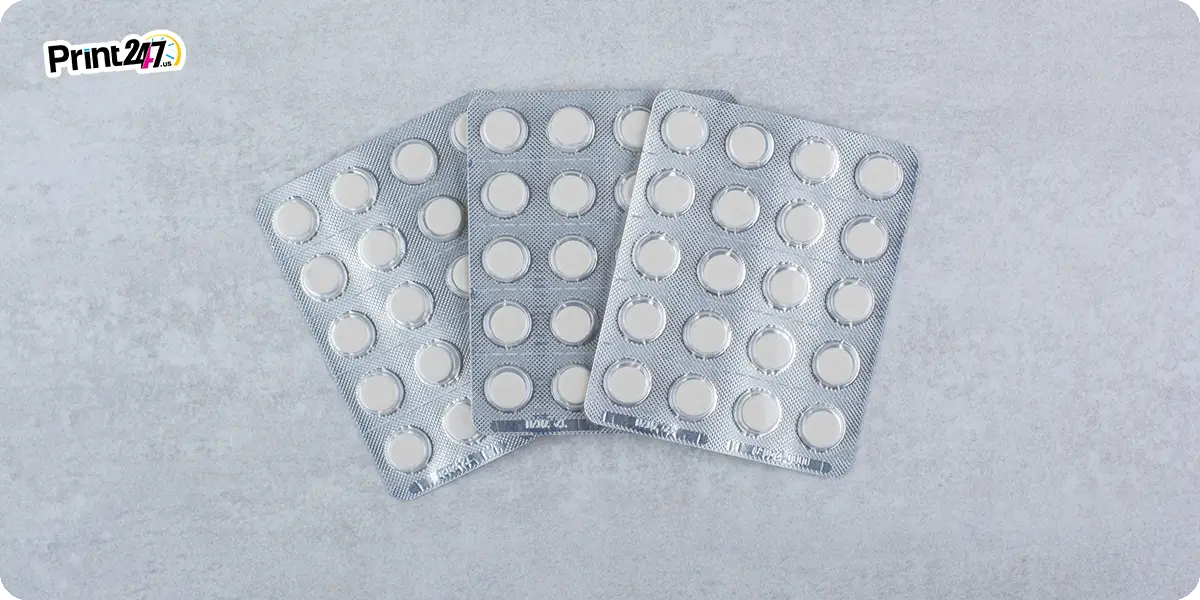

Have you seen the distinction that blister packaging carries for tablets and capsules? These are packaged in ways that you get reasonably regulated medicine packaging. From being a stiff and fixed-size item, the capsule or tablet goes into a rigid cavity; later on, there is a flexible cover stamped on it to finish the package. Giving a protective measure to your pharmaceutical products is essential and generally, items like capsules and tablets these good are handled in a uniform manner, which reduces the chances of error to a maximum level. Moreover, blister packaging has an attractive feature in that each cavity remains independent. It also tends to be interdependent.

With sterility or quality of the product is compromised when the seal between two cavities is broken unless one of the blisters leaks outside of the package. There are several medications susceptible to moisture; the blister pack ensures that your packaging remains in the best state. The drug delivery in these circumstances is quite ineffective within minutes of being in the average room temperature. Supposedly, if the a leak between two cavities, the second cavity will be damaged as the cavity of the first item is consumed.

Why Pharmaceutical Businesses Prefer Blister Packaging?

A precise dosage control: every dose of medicine comes in specific packaging, and the blister packs offer dose control. This is essential to patients that must stick to their prescribed medication regimens. The compartments that are clearly marked on blister packs make it simple for patients to keep track of and determine their dosages, which reduces the chance of mistakes in dosage and increases the patient's acceptance.

Additionally, it extends the longevity of the shelf-life of medications as it protects their contents from outside influences that could affect their quality. The airtight and lightweight structure of the blister packaging shields the medicines from degradation, oxidation, absorption, as well as degrading, thus preserving their efficacy in time. Although protection and preservation of the integrity of the product are the main reasons for blister packing, there are many more motives why pharmaceutical companies use it:

- The product will be apparent

- Good quality seal and easy-to-detect leaks

- Simpler to manufacture in high numbers followed by great speed

- Cost-effective

Caution:

- Clean and organized area to follow instructions as well as mandatory details

- More colors and styles for increased selling value

- Dissuasion to altering

Patient Compliance

- Patients are able to monitor the tablets they consume

- Increased shelf life for product shelf life

- Lightweight, which substantially reduces costs for transportation

- Maintains dose accuracy

it is easy to get rid of a tablet or capsule just by pressing the blister

Different Types of Blister Packaging

For pharmaceutical blister packaging there are a variety of types used, such as thermoformed, cold-formed and face-seal packages. They are mostly used to package capsules and tablets, providing individual dosage packaging as well as protection from the effects of environmental elements.

Blister packaging provides a broad variety of options: among the options are PVC PCTFE PVDC along with thermoform and thermal blisters for products with less sensitivity and cold form Alu-Alu blisters to protect active pharmaceutical Ingredients (APIs), which have a higher sensitivity. You can acquire the best blister card packaging made by Print247.

There are currently primary 6 types of packaging used for pharmaceutical packaging.

The cavity is made from clear thermoformed plastic. The lid is made of clear plastic or any combination of paper, plastic or foil.

The second type of cavity contains foil, which is the primary component of both webs. The process of stretching cold forms the cavity.

The Principal Benefit of Blister Packaging

In the pharmaceutical industry, blister packaging helps protect the medicine and other products from

- Physical damage

- mechanical damages

- Bio-contamination and degradation

- Protects Theft or counterfeiting

all external influences that may negatively affect or alter properties

Cold-formed Foil

Cold-Form pharma blister packaging has been well-known among Americans as the gift pack comprised of foil, film or multi-material backing, which is attached to an unformed sheet of thermoformed blisters. A less popular kind of blister is foil or lamination, which is used to protect products that are more sensitive to light or moisture. As opposed to the all-plastic type of blisters, these aren't thermoformed but can be cold-pressed in order to create a shape.

The products that need the greatest amount of protection are placed with foil in complete packaging. Cold-formed foil has increased as more water-sensitive products are available. Cold-formed foils are gaining recognition due to the fact that it's the sole substance that offers a 100% barrier against oxygen, moisture, and light. It has also facilitated the expansion of ways in which the blisters can be utilized, which allows the safe packing of fragile goods

Thermoformed Blister Packs

They are made by heating sheets of plastic that are compressed into molds, forming blister pockets.

- The most common materials are PVC PET and often aluminium.

- The seal is made by using aluminum foil, paperboard and plastic films.

Cold-Formed Blister Packs

The cold-formed blister packs also tend to be referred to as Alu-packing. They utilize aluminium foil for the blisters. This approach is especially efficient in the case of medications sensitive to moisture. The cavities for the blisters are created by pressing aluminium foil. It is considered an ideal option for packaging sensitive pharmaceutical items.

Face-Seal Blister Packs:

This type of item is formed around the plastic blister that is later encased inside a carton or paperboard. It is common for plastics to be transparent in order to let you see the item. The paperboard could have been engraved to make it easier for you to access.

It's an essential form of packaging in relation to the packaging of pharmaceuticals. It's a type of pre-form plastic packaging where machines create pockets or cavities out of a plastic sheet the aid of heating or pressure.

Kraft Blister Packaging

In the pharmaceutical industry Kraft blister packs are pertinently popular; these are typically prepared from the foil or plastic but tend to have a kraft paper backing. These blister packs are commonly best for pills, capsules and have also been pertinent for oral solid dosages.

Blister cards protect medicine against inclement weather conditions.

Kraft blister packaging in pharmaceuticals refers to using blister packs, which are typically made of plastic or foil, with a kraft paper or cardboard backing. These blister packs are commonly used to package pills, capsules, or other oral solid dosage forms. The blister pack protects the medication from environmental factors and provides a degree of tamper resistance.

Blister Trays

Yes, these blister trays are pivotal for the pharmaceutical industry, like the need for laboratories, vials, tubes, and syringes, these blister tray helps you with the exceptional packaging solution.

Blister tray containers are used primarily to package items

- Medicines

- Food Items

- Hardware tools

- Toys etc.

- Benefits of Blister Trays

- Make sure the product is fresh

- Make sure to have a uniform size and amount

- Secure

- The possibility of customizing is there

- Product visualization

Single-Seal Blister Packs

These offer a single, reliable seal for product protection, though not as commonly used as other types. The packaging of the strip: Similar to blister packaging, however, it could require more conventional strip packaging materials. It is best to upkeep medicine in the most pristine condition.

Last Thoughts On Medical Blister Packaging

Blister packaging has a major role in the pharmaceutical industry, along with other significant industries. Based on the nature of the product and the quality, the appropriate sort of blister packaging should be picked. We are hoping that you've gained enough details from this article on different varieties of blister packaging, and that will assist you in making the right decision to package your item. With Print247, you can upscale your pharmaceutical product safety by adopting top-quality blister packaging. Blister card packaging trends have become very popular so you can adopt this to preserve the appeal and security of your medicinal items.

.jpg)

.jpg)

.jpg)